Preparation method of polyesterimide insulating paint and polyesterimide insulating paint

A polyesterimide, insulating paint technology, applied in sustainable manufacturing/processing, coating, climate sustainability, etc., can solve the problems of complex feeding sequence of production process, volatile raw materials, and high reaction temperature, so as to improve the reaction Quality, heat resistance improvement, effect of heat resistance improvement and chemical resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

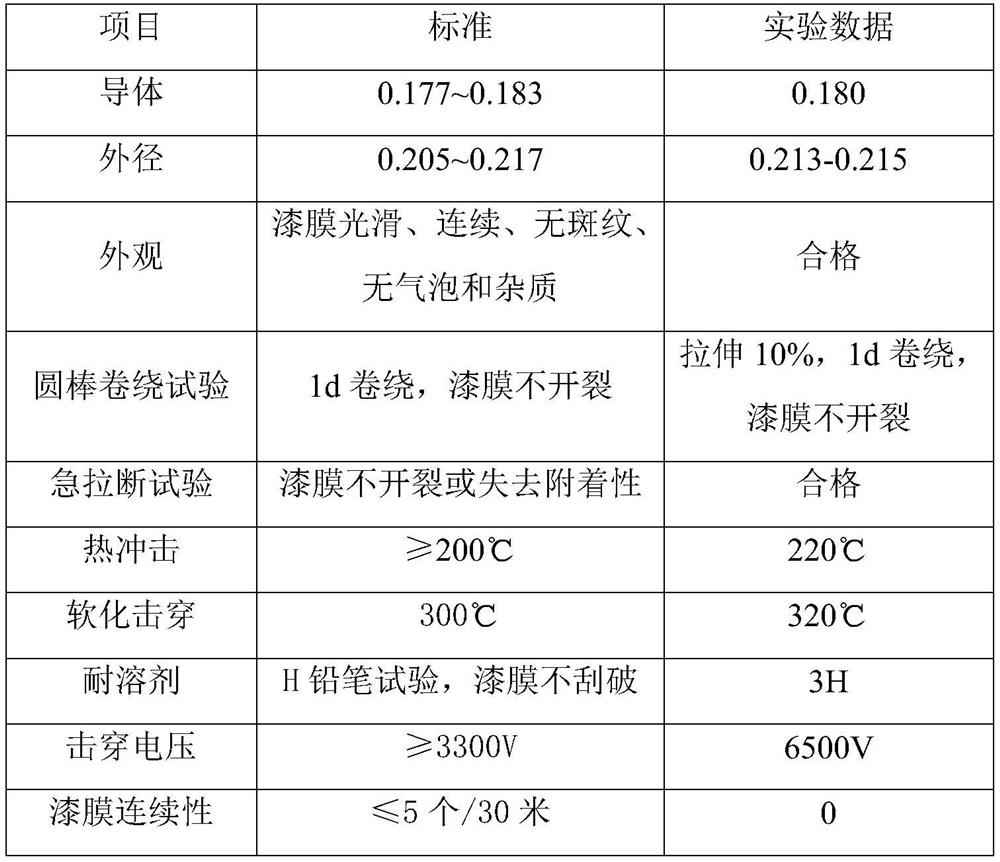

Image

Examples

Embodiment 1

[0036] This embodiment discloses a preparation method of polyesterimide insulating paint, which includes the following steps:

[0037] S1. Weigh the raw materials of the following formula amounts: 8 parts of trimellitic anhydride, 4 parts of aromatic diamine, 10 parts of diol, 8 parts of glycerol; 22 parts of dimethyl terephthalate, trihydroxyethyl isocyanurate 8 parts of acid ester, 15 parts of xylene, 30 parts of mixed cresol, 4 parts of N-methyl pyrrolidone, 2 parts of butyl orthotitanate, 1 part of resin, wherein the resin is phenolic resin, amino resin, One or more of acrylic resins;

[0038] S2, after described reaction vessel is dried, add described N methyl pyrrolidone solvent after nitrogen 5min, add the trimellitic anhydride of partial amount, be warming up to 100 ℃ under stirring, be incubated for 1 hour until trimellitic anhydride dissolves;

[0039] S3. Divide the aromatic diamine into six equal parts, add one part of the aromatic diamine, and keep the reaction f...

Embodiment 2

[0050] This embodiment discloses a preparation method of polyesterimide insulating paint, which includes the following steps:

[0051] S1. Weigh the raw materials of the following formula amounts: 10 parts of trimellitic anhydride, 6 parts of aromatic diamine, 15 parts of diol, 10 parts of glycerol; 28 parts of dimethyl terephthalate, trihydroxyethyl isocyanurate 12 parts of acid esters, 20 parts of trimethylbenzene, 50 parts of mixed cresols, 8 parts of N-methylpyrrolidone, 3 parts of butyl orthotitanate, and 3 parts of resins, wherein the resins are phenolic resins, amino resins, One or more of acrylic resins;

[0052] S2, after described reaction vessel is dried, add described N-methyl pyrrolidone solvent after 10min of nitrogen, add the trimellitic anhydride of partial amount, be warming up to 140 ℃ under stirring, be incubated for 0.5 hour until trimellitic anhydride dissolves;

[0053] S3. Divide the aromatic diamine into eight equal parts, and by adding one part of the...

Embodiment 3

[0064] This embodiment discloses a preparation method of polyesterimide insulating paint, which includes the following steps:

[0065] S1. Weigh the raw materials of the following formula amounts: 9 parts of trimellitic anhydride, 5 parts of aromatic diamine, 12 parts of diol, 9 parts of glycerol; 25 parts of dimethyl terephthalate, trihydroxyethyl isocyanurate 11 parts of acid ester, 17 parts of xylene, 40 parts of mixed cresol, 5 parts of N-methyl pyridinone, 2.5 parts of butyl orthotitanate, 2 parts of resin, wherein, the resin is phenolic resin, amino resin, One or more of acrylic resins;

[0066] S2, after the reaction vessel is dried, add the N-methylpyrrolidone solvent after 7min of nitrogen, add a partial amount of trimellitic anhydride, be warming up to 120 ° C under stirring, and be incubated for 0.8 hours until the trimellitic anhydride dissolves;

[0067] S3. Divide the aromatic diamine into ten equal parts, and keep the reaction for 0.8 hours by adding one part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com