Hydrocarbon material lift pipe reactor

A technology of a reactor and a riser, which is applied in the field of a riser reactor for catalytic conversion of hydrocarbon feedstocks, can solve the problems of difficulty in realization, inability to improve reaction, coordination of reaction processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

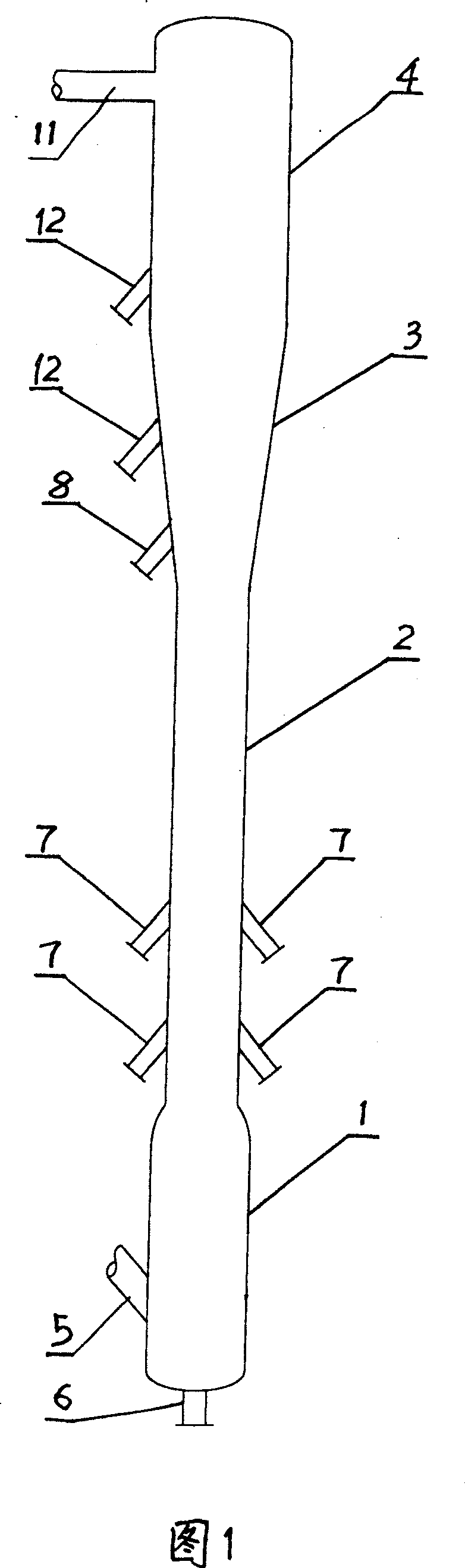

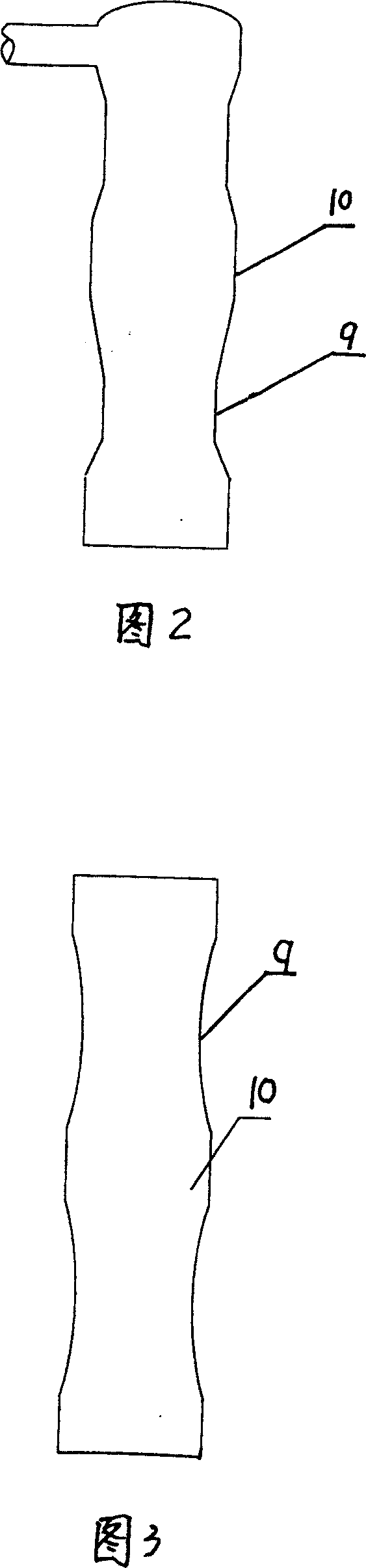

[0014] Embodiment 1. A riser reactor for hydrocarbon raw materials is divided into a pre-lift section 1 and three reaction sections 2, 3, and 4 from bottom to top. The pre-lift section 1 and the three reaction sections 2, 3, and 4 are coaxially connected in series. The pre-lifting section 1 has a total height of 5 meters, a lower part with a diameter of 1.5 meters and a height of 2.5 meters, an upper part with a diameter of 0.8 meters and a height of 2.5 meters, a catalyst inlet pipe 5 with a diameter of 0.7 meters in the lower part, and a pre-lifting medium connecting pipe 6 at the bottom. The first reaction section 2 is equal in diameter up and down, with a diameter of 0.8 meters and a height of 15 meters. The lower part is provided with two layers of feeding nozzles 7, four in the lower layer and two in the upper layer. 3 meters apart. The lower end of the second reaction section 3 has a diameter of 0.8 meters, a taper of 10 degrees, and a height of 6.5 meters. The side wal...

Embodiment 2

[0015] Embodiment 2. In this embodiment, the upper and lower sides of the pre-lift section 1 are equal in diameter, with a diameter of 1.5 meters. The second reaction section 3 has a taper of 20 degrees. The third reaction section 4 adopts the zoom-type structure in Fig. 3, with a total height of 15 meters and a diameter reduction every 2 meters. The diameter of the oil and gas outlet pipe is 1.2 meters. In this embodiment, there is no connecting pipe for oil and gas refining. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com