Cladding layer of valve sealing surface

A valve sealing and cladding layer technology, which is applied in the coating, metal material coating process, etc., can solve problems affecting the application of laser technology, and achieve the effects of large-scale production, high hardness, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment relates to the cladding layer of the valve sealing surface.

[0033] A cladding layer of a valve sealing surface, the alloy powder of the cladding layer includes the following raw material components in mass percentage:

[0034] Carbon 1.1~2.0%, Chromium 19.5~20.0%, Nickel 3.6~4.0%, Molybdenum 1.0~1.4%, Boron 2.0%, Silicon 3.0%, Tungsten 1.5~2.0%, Vanadium 0.51~0.6%, Lanthanum≤0.05%, Yu The amount is iron.

[0035] The raw material formula of alloy powder in each embodiment is as shown in the table below:

[0036] Example 1.1 Example 1.2 Example 1.3 carbon 78g 87.5g 140g chromium 1365g 1397g 1395g nickel 252g 267.5g 280g molybdenum 70g 90g 98g boron 140g 140g 140g silicon 210g 210g 210g tungsten 105g 124g 140g vanadium 36g 36g 42g lanthanum 3.5g 3.5g 3.5g iron 4740.5g 4644.5g 4551.5g

[0037] The preparation method of each embodiment alloy powder in the ...

Embodiment 2

[0047] This embodiment relates to the detection of the performance of the cladding layer on the sealing surface of the valve in the first embodiment.

[0048] The alloy powder of Example 1.1 is compared with the cladding layer prepared by the laser cladding process of the present invention with the cladding layer prepared by the plasma spray welding process of the same alloy powder. The structure and phase, the thickness and quality of the dissolved layer, the composition and dilution rate of the dissolved layer, the hardness of the dissolved layer, the wear resistance of the dissolved layer and the corrosion resistance of the dissolved layer were tested. The test results are as follows:

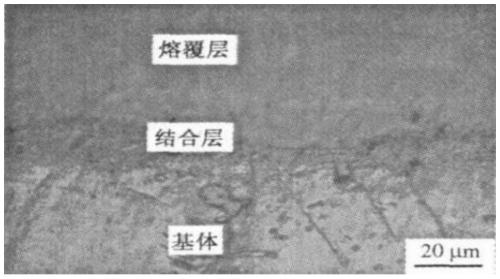

[0049] (1) Detection of the combination of the solution layer and the matrix

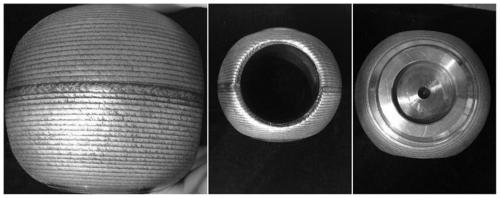

[0050] Analyzing the metallographic structure of the molten layer treated by laser cladding and plasma spray welding process see figure 2 , along the vertical direction of the processing surface, it can be divid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com