Structure and preparation method of novel high-thermal-conductivity s electronic packaging base plate material

An electronic packaging and high thermal conductivity technology, which is applied in the structure and preparation of substrate materials for new high thermal conductivity electronic packaging, can solve the problems of large thermal expansion coefficient and insignificant improvement of thermal conductivity, so as to reduce thermal expansion coefficient, improve thermal conductivity, and reduce thermal conductivity. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

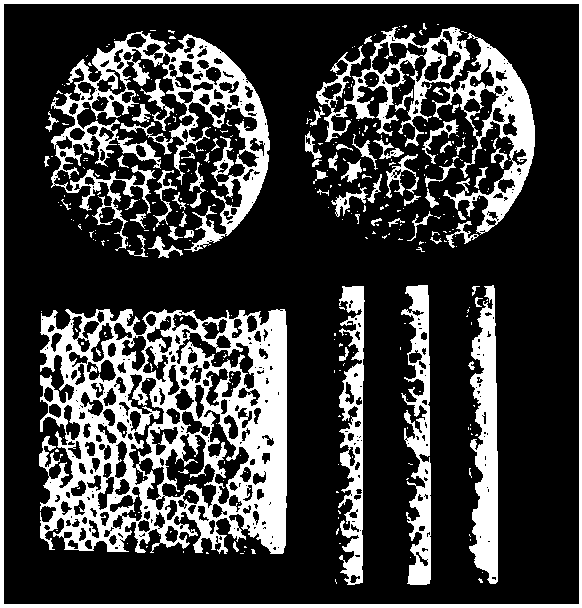

[0028] 1) Preparatory steps: prepare ceramic slurry; polyurethane foam sponge, size is 48cm*48cm*20cm, volume density is 0.0286g / cm 3 ; PT-7016 type epoxy resin (A) and curing agent (B), the viscosity after mixing is 600cps, the curing time is 6h at 25°C, 1h at 50°C, and the volume resistivity (50HZ) is 1.6×10 15Ω·cm; other preparation materials include epoxy resin defoamer XYS-6201 (foam breaking polyorganosiloxane), silicone mold, etc.

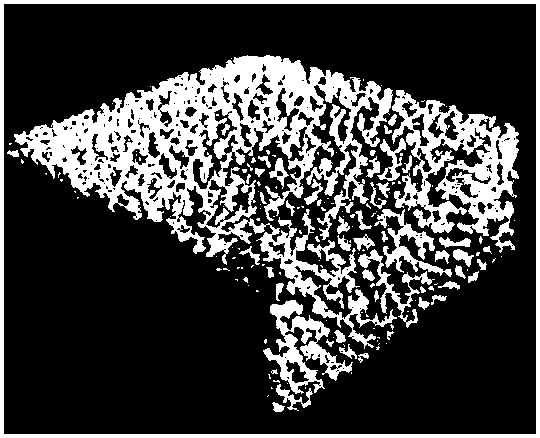

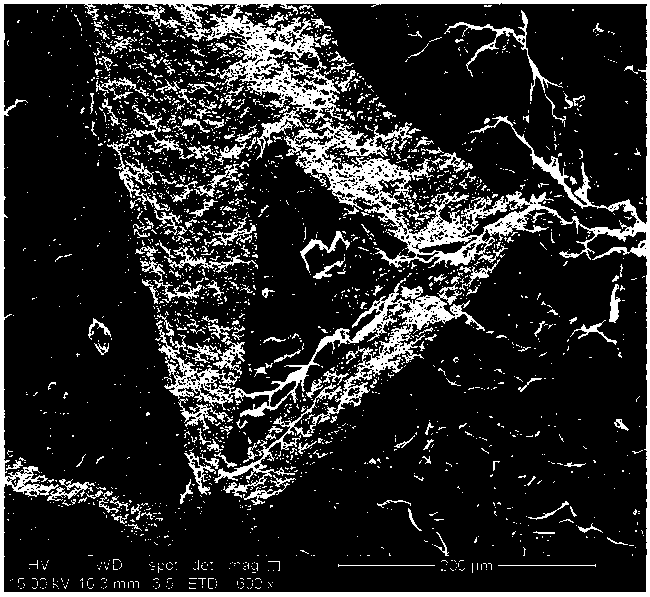

[0029] 2) Making a mesh porous ceramic skeleton: use w(NaOH)=20% NaOH solution to treat the polyurethane foam for 3 hours respectively, then wash and dry it with water, and use w(PVA)=5% PVA solution to its surface modified, and then the α-Al 2 o 3 The ceramic slurry prepared with powder as the main raw material is coated on the surface of the pretreated polyurethane foam, and then the reticular porous ceramic skeleton is prepared by extrusion, drying and calcination. The porosity of the prepared reticular porous ceramic skeleton is 92.5%....

Embodiment 2

[0033] 1) Preparatory steps: prepare ceramic slurry; polyurethane foam sponge, size is 48cm*48cm*20cm, volume density is 0.0597g / cm 3 ; PT-7016 type epoxy resin (A) and curing agent (B), the viscosity after mixing is 600cps, the curing time is 6h at 25°C, 1h at 50°C, and the volume resistivity (50HZ) is 1.6×10 15 Ω·cm; other preparation materials include epoxy resin defoamer XYS-6201 (foam breaking polyorganosiloxane), silicone mold, etc.

[0034] 2) Making a mesh porous ceramic skeleton: use w(NaOH)=20% NaOH solution to treat the polyurethane foam for 3 hours respectively, then wash and dry it with water, and use w(PVA)=5% PVA solution to its surface modified, and then the α-Al 2 o 3 The ceramic slurry prepared with powder as the main raw material is coated on the surface of the pretreated polyurethane foam, and then the reticular porous ceramic skeleton is prepared by extrusion, drying and calcination. The porosity of the prepared reticular porous ceramic skeleton is 88.3%...

Embodiment 3

[0038] 1) Preparatory steps: prepare ceramic slurry; polyurethane foam sponge, the size is 48cm*48cm*20cm; PT-7016 epoxy resin (A) and curing agent (B), the viscosity after mixing is 600cps, and the curing time is 25°C 6h, 1h at 50°C, volume resistivity (50HZ) 1.6×10 15 Ω·cm; silane coupling agent KH-560; other preparation materials include epoxy resin defoamer XYS-6201 (foam breaking polyorganosiloxane), silicone mold, etc.

[0039] 2) Making a mesh porous ceramic skeleton: use w(NaOH)=20% NaOH solution to treat the polyurethane foam for 3 hours respectively, then wash and dry it with water, and use w(PVA)=5% PVA solution to its surface modified, and then the α-Al 2 o 3 The ceramic slurry prepared with powder as the main raw material is coated on the surface of the pretreated polyurethane foam, and then the reticular porous ceramic skeleton is prepared by extrusion, drying and calcination. The porosity of the prepared reticular porous ceramic skeleton is 88.3%. , bulk dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com