Vacuum furnace remelting method of boiler membrane wall anti-corrosion coating

An anti-corrosion coating, vacuum furnace technology, applied in the coating, metal material coating process, melting spray plating and other directions, can solve the limited service life of ordinary stainless steel, coating failure, aggravating the uneven oxide scale of coating heating growth and other problems, to achieve the effect of accurately adjusting the temperature in the furnace, prolonging the service life and eliminating potential risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

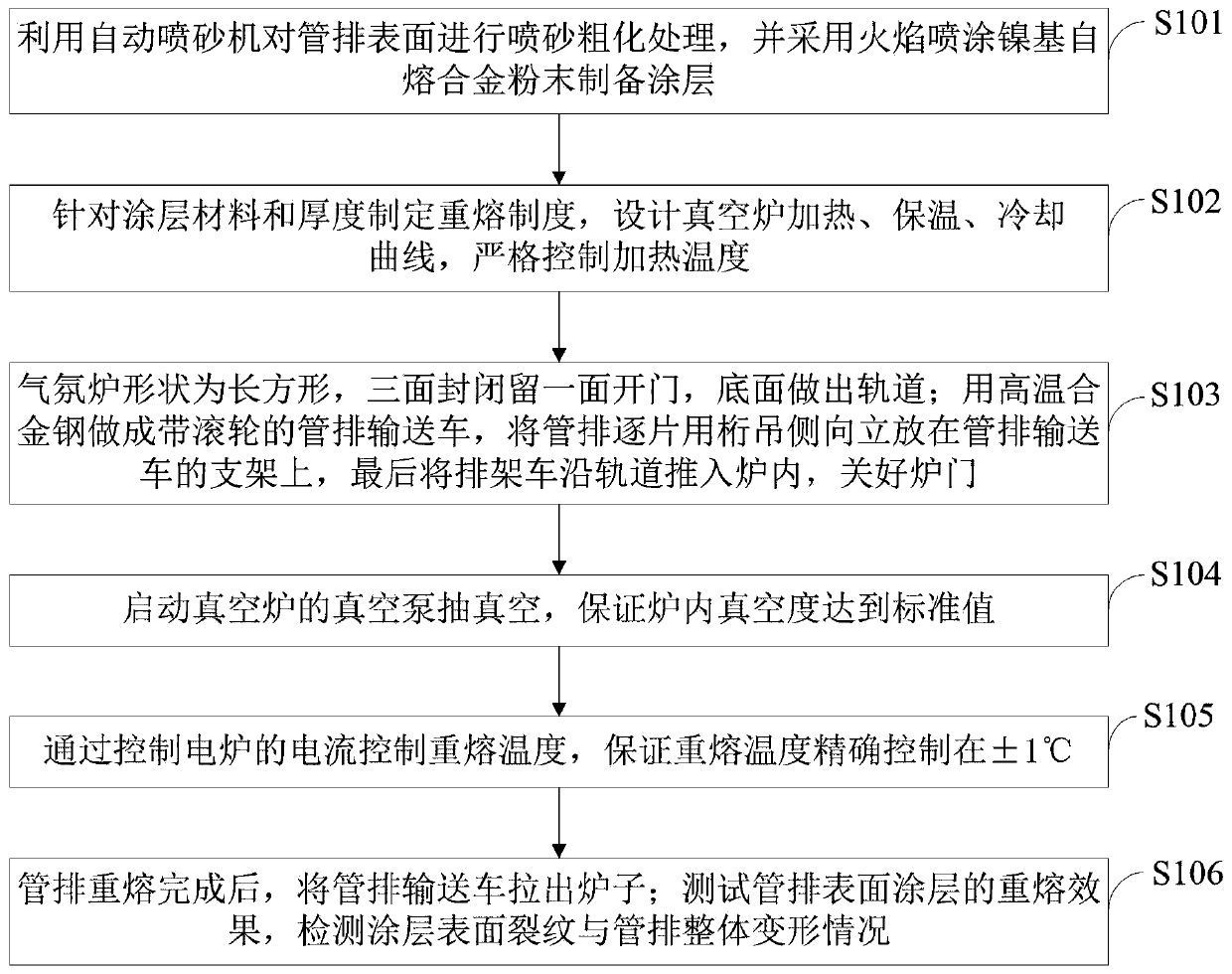

[0054] Embodiment: The vacuum furnace remelting method of the boiler membrane wall anticorrosion coating comprises the following steps:

[0055] 1. The automatic sandblasting machine performs sandblasting roughening on the surface of the pipe row.

[0056] 2. The coating is prepared by flame spraying nickel-based self-fluxing alloy powder.

[0057] 3. Formulate the remelting system according to the coating material and thickness, and design the reasonable heating, heat preservation and cooling curves of the vacuum furnace. The most important thing is to strictly control the heating temperature. The heating temperature is generally set at 10°C-30°C above the solidus line of the alloy , If the solid phase point of the nickel-based self-fluxing alloy is 1035°C and the liquid phase point is 1280°C, the furnace temperature should be set at 1045°C-1065°C.

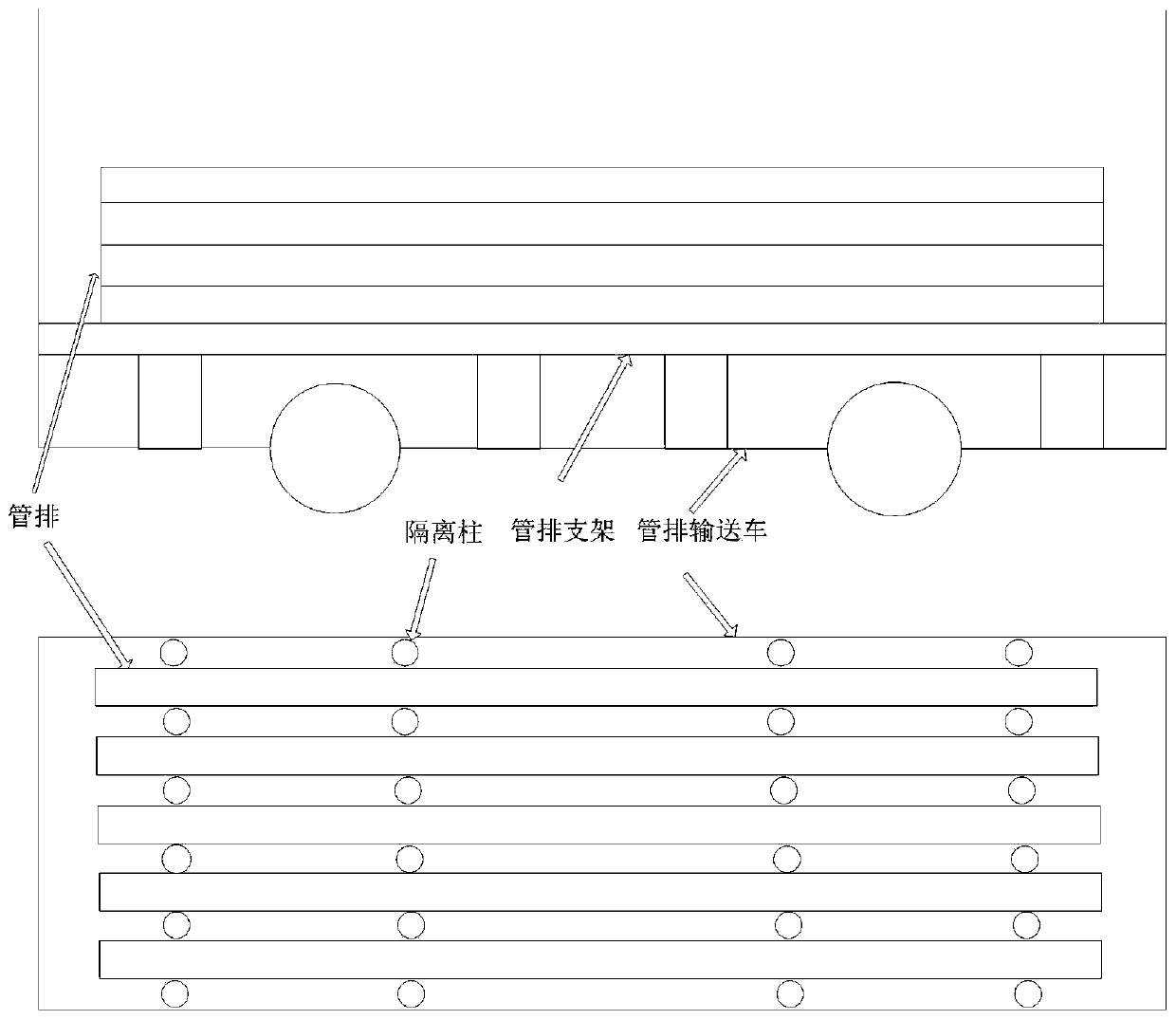

[0058] 4. The shape of the vacuum furnace is rectangular, and the other sides are closed, leaving only one side to open the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com