Treatment method of organic silicon production wastewater

A technology for the production of wastewater and treatment methods, applied in the direction of sedimentation treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of ozone depletion, difficult to reach water, and difficult to crack siloxane, so as to reduce investment cost and operation Cost, reduction of COD value, effect of reduction of ozone consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

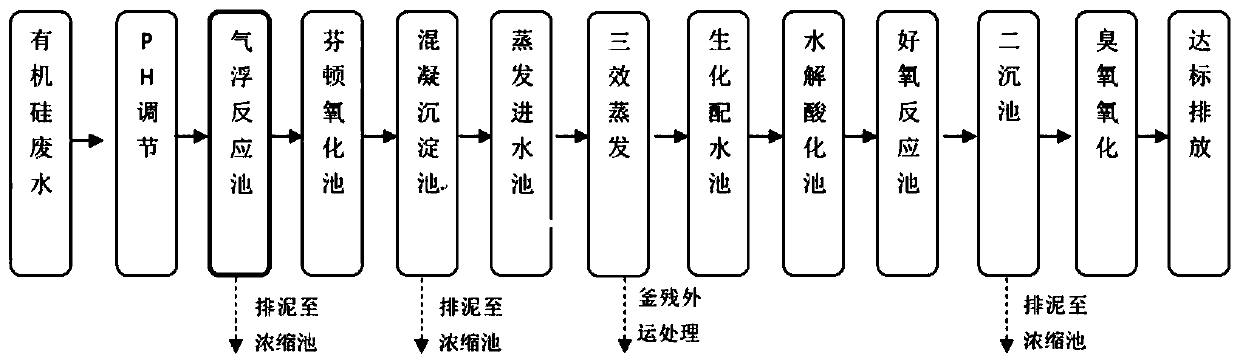

[0033] The process flow chart of the treatment method of the present invention's treatment of organic silicon production wastewater is as figure 1 As shown, pass the organic silicon production wastewater into the air flotation tank, remove the slick oil in the wastewater, add sodium hydroxide to adjust the pH to 3, and add 14g of 2% ferrous sulfate solution and 5g of 27.5% hydrogen peroxide per liter of air flotation water , carry out the Fenton oxidation reaction, the reaction time is 2h; add sodium hydroxide to the obtained wastewater to adjust the pH to be greater than 7, then add a coagulant, add 5 mg of coagulant to every 1L of wastewater, pass it into the coagulation sedimentation tank, and discharge the supernatant, The sludge is transported outside for disposal, and the supernatant is passed into a three-effect evaporation to remove salt by evaporation. The residual liquid of the evaporation kettle is used as hazardous solid waste and sent to the hazardous waste disposa...

Embodiment 2

[0037]Pass organic silicon production wastewater into the air flotation tank, remove the slick oil in the wastewater, add sodium hydroxide to adjust the pH to 4, add 10g of 8% ferrous sulfate solution and 8g of 27.5% hydrogen peroxide per liter of air flotation water, and carry out fen Oxidation reaction, the reaction time is 4 hours; the obtained wastewater is adjusted to a pH greater than 7 by adding sodium hydroxide, and a coagulant is added, and 5mg of a coagulant is added to each 1L of wastewater, which is passed into the coagulation sedimentation tank, the supernatant is discharged, and the sludge is separated. For external disposal, the supernatant is passed into the second-effect evaporation to remove salt, and the residual liquid of the evaporation kettle is used as hazardous solid waste and sent to the hazardous waste disposal center. The evaporative condensate is passed into the biochemical water inlet pool, the water temperature is controlled at 25°C and activated s...

Embodiment 3

[0041] The processing step of this implementation 3 is roughly the same as that of Example 2, and the difference is that the present Example 3 does not adopt Fenton and evaporation pretreatment, and the specific result data are as shown in Table 3:

[0042] table 3

[0043] index raw water air flotation A-O biochemistry Ozone oxidation COD 2500 2250 450 250 Inorganic silicon 18 18 28 108 Silicone 230 215 200 120 total silicon 250 230 230 230

[0044] In conjunction with Table 2 and Table 3, it can be concluded that the air flotation-Fenton oxidation pretreatment process of the present invention can degrade biodegradable substances in wastewater, greatly reduce the COD value, and leave refractory organic silicon and siloxane and other organic matter. Among them, air flotation removes oil slicks in wastewater, and after recycling, it returns to the production process for reuse. The Fenton oxidation process modifies waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com