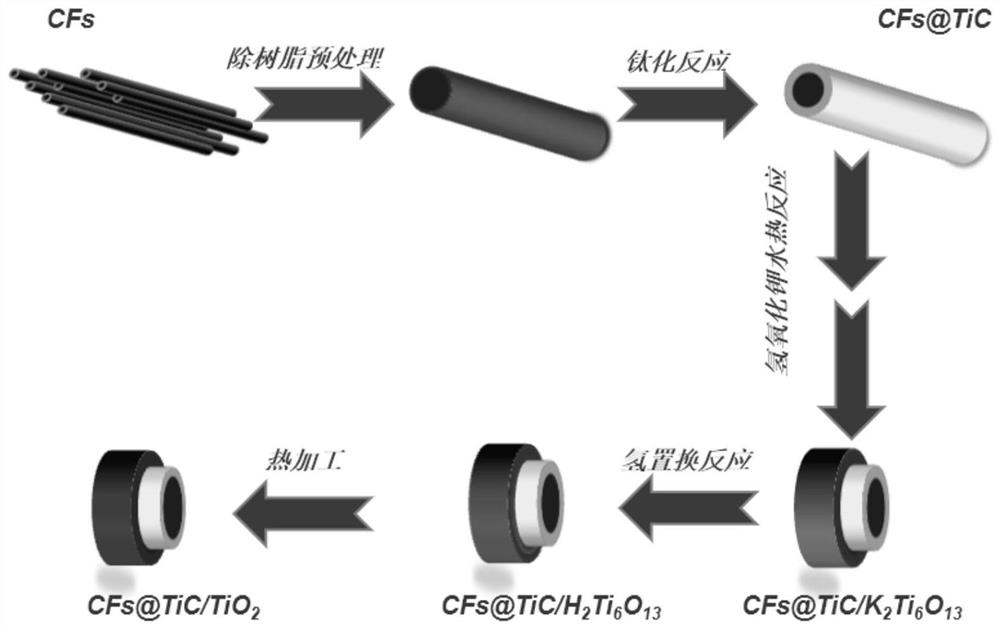

acfs@tic/tio 2 Composite materials and their preparation methods and applications

A composite material and mixture technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of fiber strength and performance damage, complexity, environmental pollution, etc., to achieve catalytic performance, prevent The effect of falling off and avoiding secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

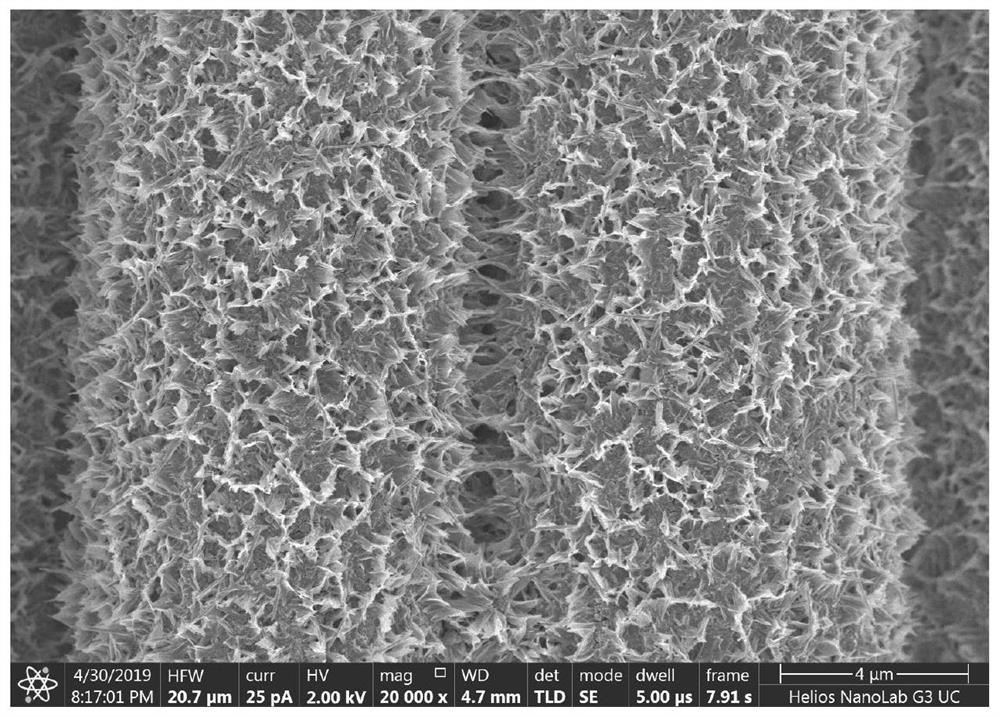

[0054] 1) First, remove the glue on the carbon fiber to obtain a single dispersed fiber. Use a Soxhlet extractor to hold the fiber bundle coated with resin, and use acetone steam to reflux back and forth to wash off the resin on the fiber surface. The temperature is controlled at 80°C and the time is controlled. At 72h, take out the fibers, dry them in vacuum at 105°C for 24h in a vacuum oven, and take them out for use;

[0055] 2) Titanium hydride powder and KCl (analytical pure) particles are fully mixed in the sample mixer, Ti: C = 0.5 (molar ratio), the amount of KCl added is 10 times the mass of the reactant, and carbon fibers are dispersed in titanium hydride and KCl Put the alumina crucible into the alumina crucible, put the alumina crucible in the tube furnace, pass in argon as the protective gas, program the temperature rise, the heating rate is 10°C / min, and the temperature is raised to 1000°C. Keep warm at 1000°C for 3 hours, cool down to room temperature, and contr...

Embodiment 2

[0061] 1) First, remove the glue on the carbon fiber to obtain a single dispersed fiber. Use a Soxhlet extractor to hold the fiber bundle coated with resin, and use acetone steam to reflux back and forth to wash off the resin on the fiber surface. The temperature is controlled at 80°C and the time is controlled. At 72h, take out the fiber, vacuum dry it in a vacuum oven at 105°C for 24h, and take it out for later use;

[0062] 2) Titanium hydride powder and KCl (analytical pure) particles are fully mixed in the sample mixer, Ti: C = 1.0 (molar ratio), the amount of KCl added is 10 times the mass of the reactant, and carbon fibers are dispersed in titanium hydride and KCl Put the alumina crucible into the alumina crucible, put the alumina crucible in the tube furnace, pass in argon as the protective gas, program the temperature rise, the heating rate is 10°C / min, and the temperature is raised to 1000°C. Keep warm at 1000°C for 3 hours, cool down to room temperature, and control...

Embodiment 3

[0068] Other conditions are the same as in Example 1, except that titanium hydride powder is replaced by titanium powder. After testing, the catalytic degradation rate of the sample obtained in Example 2 is 51% in 200 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com