Preparation method and device of styrene-acrylic resin

A styrene-acrylic resin and acrylic technology, applied in the field of preparation of styrene-acrylic resin, can solve the problems of limited application scope of customers, strong odor, inconvenient transportation, etc., and achieves a mild and controllable synthesis process, simple synthesis process, and reduced preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

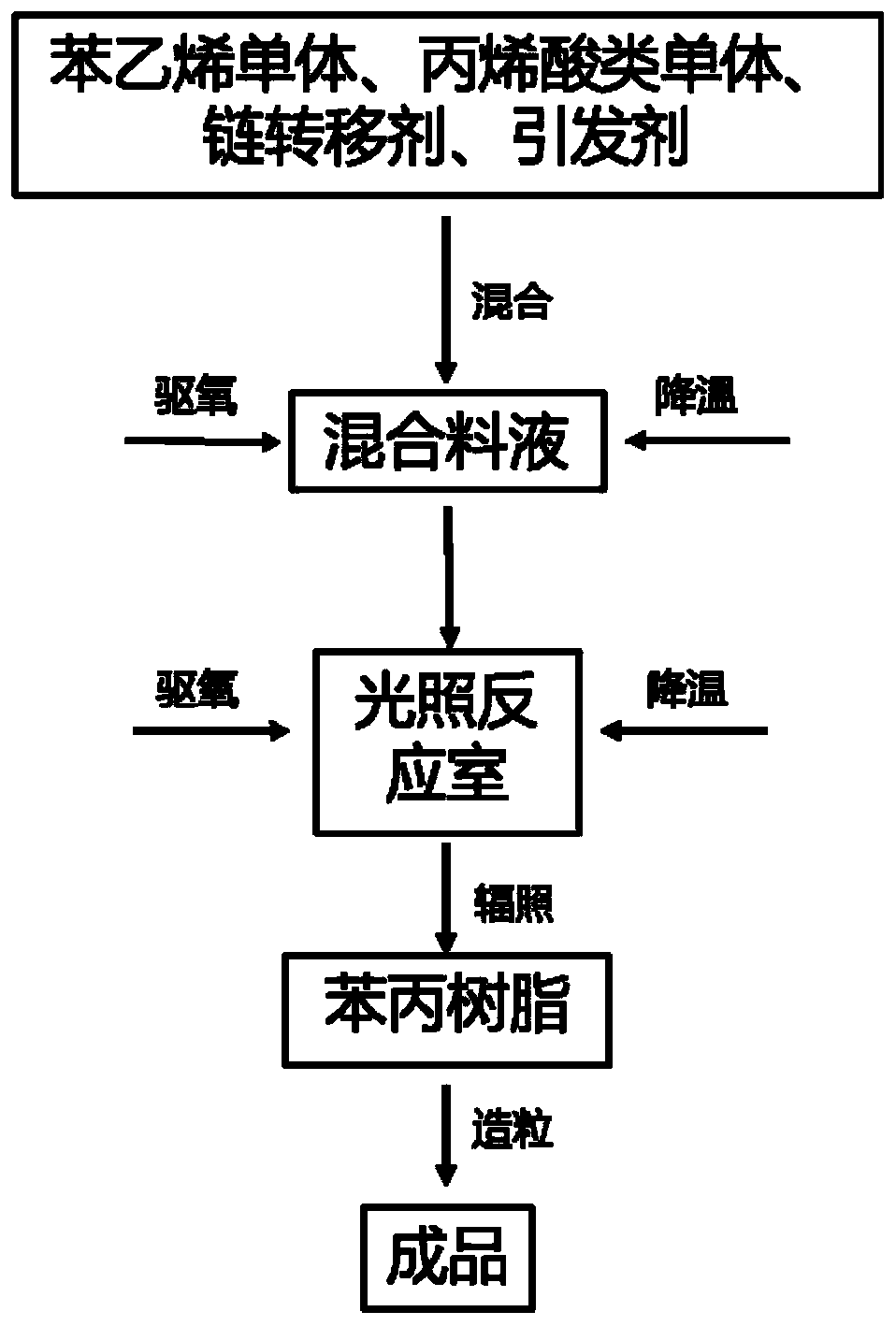

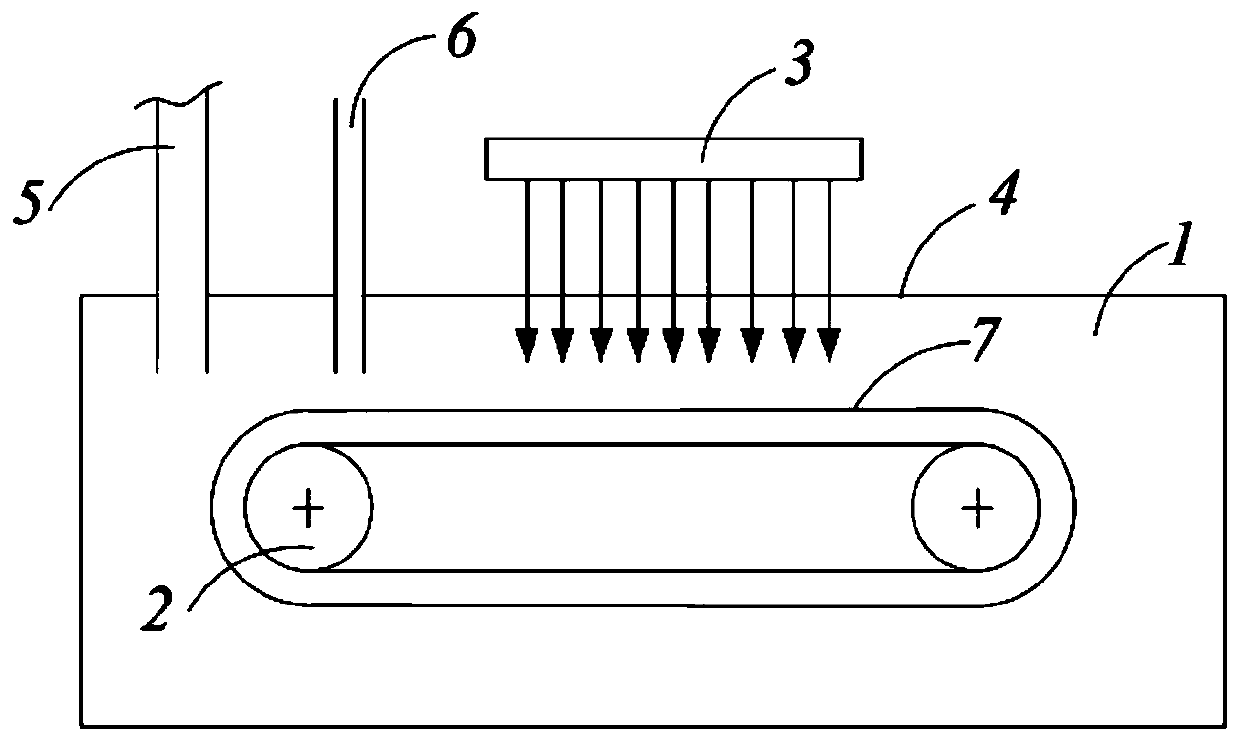

[0021] The object of the present invention is to find a method and device for preparing styrene-acrylic resin with a mild and controllable synthesis process, simple synthesis process and pure product, and provides a method for preparing styrene-acrylic resin, comprising the following steps: S1, making styrene The monomer, acrylic monomer, chain transfer agent and initiator are fully mixed uniformly, and the equipment used in the process of mixing materials is preferably a mixing tank to obtain a mixed material liquid; S2, performing the mixed material liquid in step S1 Oxygen removal and cooling, that is: carrying out the oxygen removal project on the material in the mixing tank and cooling the material liquid at the same time, further, in step S2, the temperature of the mixed material liquid after cooling is controlled at ≤ 50 ° C, and the temperature of the driving In the process of oxygen, nitrogen is preferably passed into the mixed material liquid to drive oxygen; S3, the ...

Embodiment 1

[0027] First, 100 parts by mass of styrene, 23 parts of acrylic acid, 2 parts of ethyl acrylate, 0.25 parts of AMSD and 0.3 parts of benzoyl peroxide were dissolved, fully mixed evenly, and a mixed material liquid was obtained; Next, pass nitrogen gas into the mixture liquid and lower the temperature. The time for the nitrogen gas to drive oxygen is more than 25 minutes. After cooling down, the temperature of the mixture liquid is controlled at 30° C.; Fill nitrogen to drive oxygen, and control the temperature at 30°C; again, introduce the mixture solution after oxygen drive and cooling into the light reaction chamber, apply ultraviolet light irradiation, and continuously adjust the nitrogen flow rate into the light reaction chamber , make it keep a constant temperature of 30° C., and irradiate for 14 hours to obtain block styrene-acrylic resin; finally, crush and sieve the block styrene-acrylic resin to prepare the finished styrene-acrylic resin. After testing, the finished p...

Embodiment 2

[0029]First, 100 parts of styrene, 25 parts of acrylic acid, 1 part of butyl acrylate, 2 parts of methyl acrylate, 0.5 parts of AMSD and 0.02 parts of azobisisobutyronitrile were fully dissolved, Mix evenly to obtain a mixed material liquid; secondly, pass nitrogen gas into the mixed material liquid and lower the temperature, the time for the nitrogen gas to drive oxygen is more than 20 minutes, and control the temperature of the mixed material liquid at 35 °C after cooling; at the same time , filling nitrogen into the light reaction chamber to drive oxygen, and controlling the temperature at 35° C.; again, introducing the mixture solution after oxygen drive and cooling into the light reaction chamber, and applying pulsed strong light irradiation for 12 hours. Obtain block-shaped styrene-acrylic resin; finally, crush and sieve the block-shaped styrene-acrylic resin to prepare the finished styrene-acrylic resin. After testing, the finished product does not contain organic solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com