Grignard hydrolysis two-phase separation synthesis method and device in maltol production

A synthesis method and phase separation technology, applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., to achieve pure products, avoid extensive labor, and fully react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

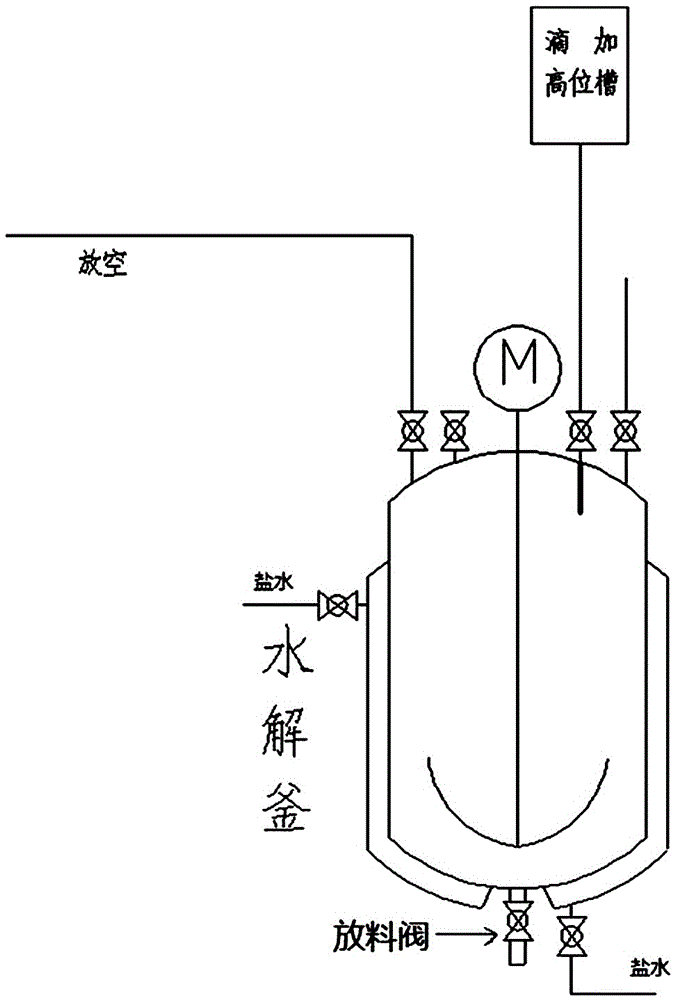

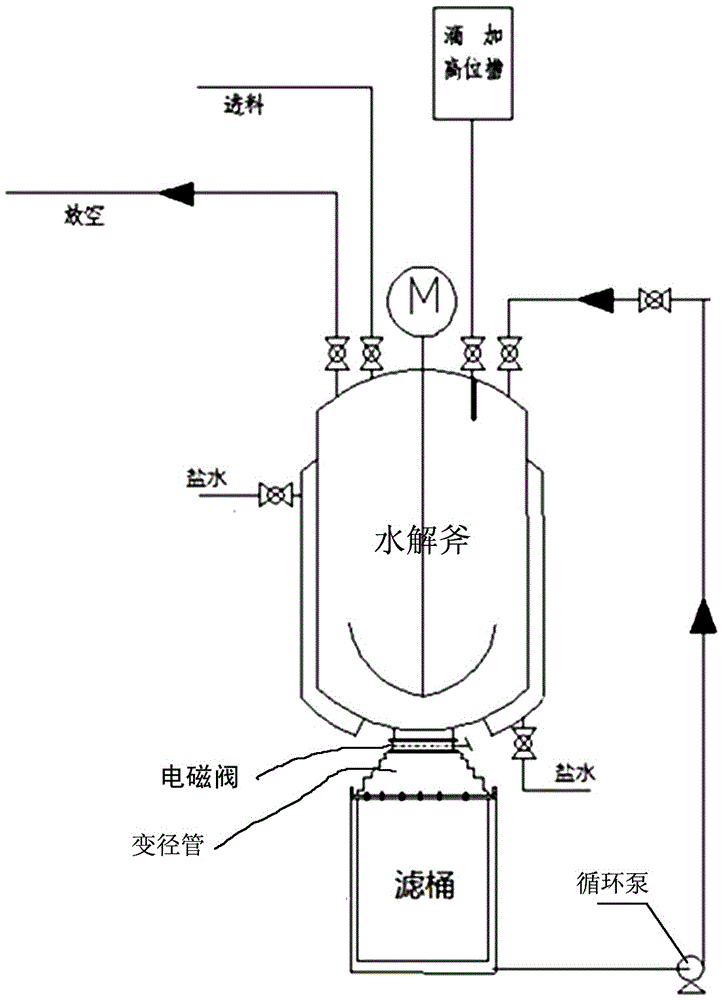

[0013] The invention provides a Grignard hydrolysis two-phase separation and synthesis device in the production of maltol, which includes a hydrolysis kettle, a dripping tank, and a stirrer, and is characterized in that:

[0014] Change the discharge port of the original Grignard hydrolysis reactor from diameter?=100mm to diameter?=200mm. After installing the solenoid valve, connect the upper end diameter? The lower end of the variable-diameter hose is connected to the upper port of the filter cartridge with a diameter of 1000 mm, and the outlet at the bottom of the filter cartridge is connected to the upper part of the hydrolysis kettle through a circulating pump.

[0015] The invention provides a kind of Grignard hydrolysis two-phase separation synthesis method in the production of maltol, comprising the steps of feeding, stirring and filtering, characterized in the following steps:

[0016] a. Put a pot of Grignard reagent (magnesium 80Kg) in a 3000L enamel hydrolysis kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com