Self-filtering reactor

A kind of reaction kettle, self-contained technology, applied in the field of reaction kettle with self-contained filter, can solve the problems of wasting raw materials, affecting product quality, doping, etc., and achieve the effect of pure product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

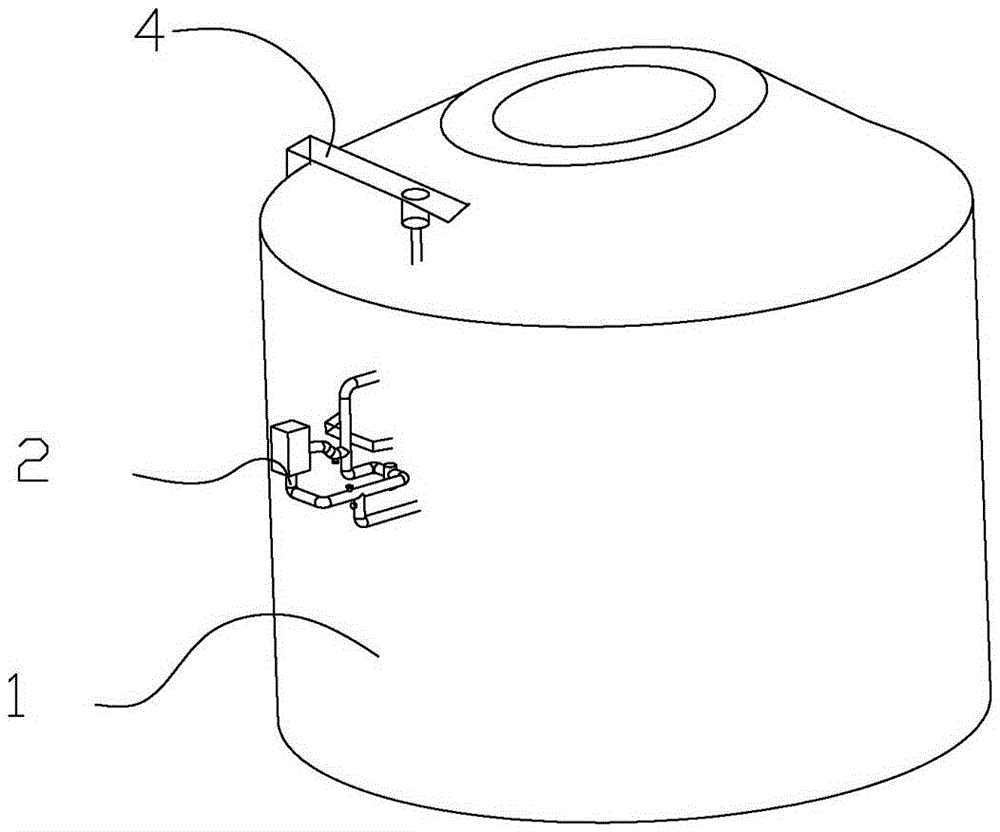

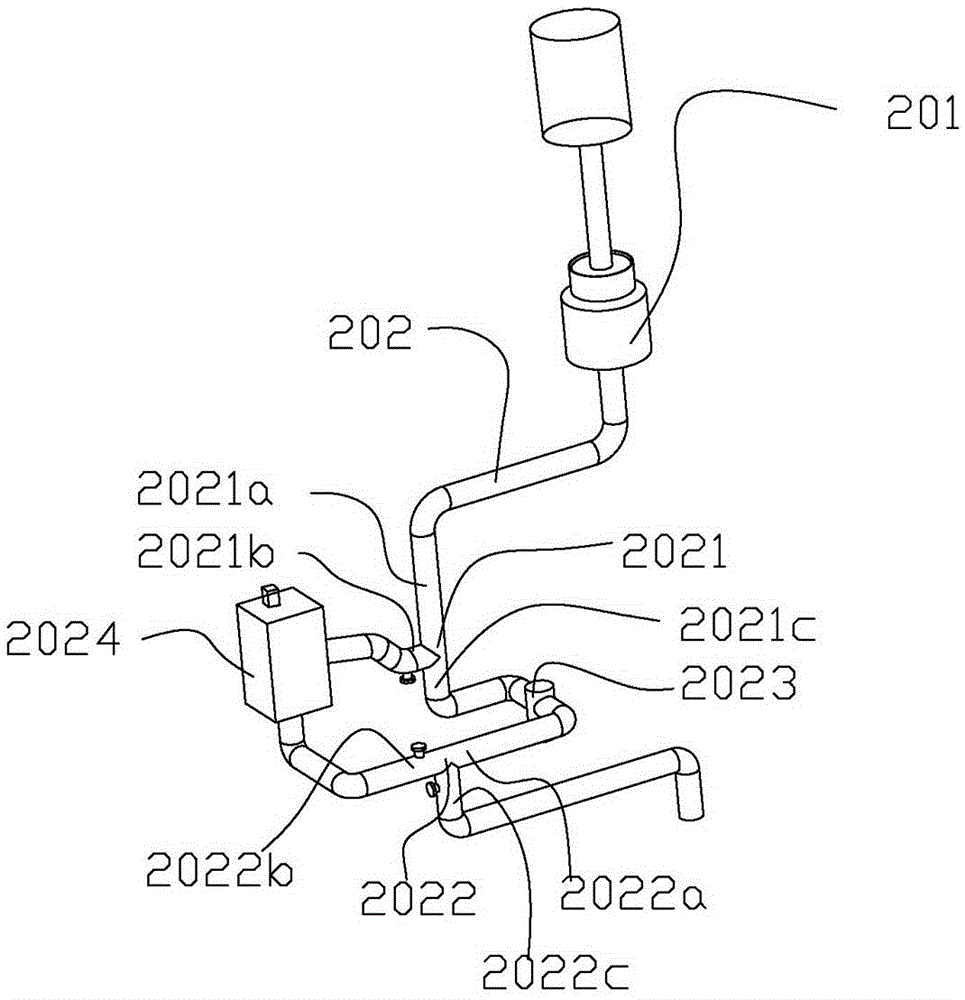

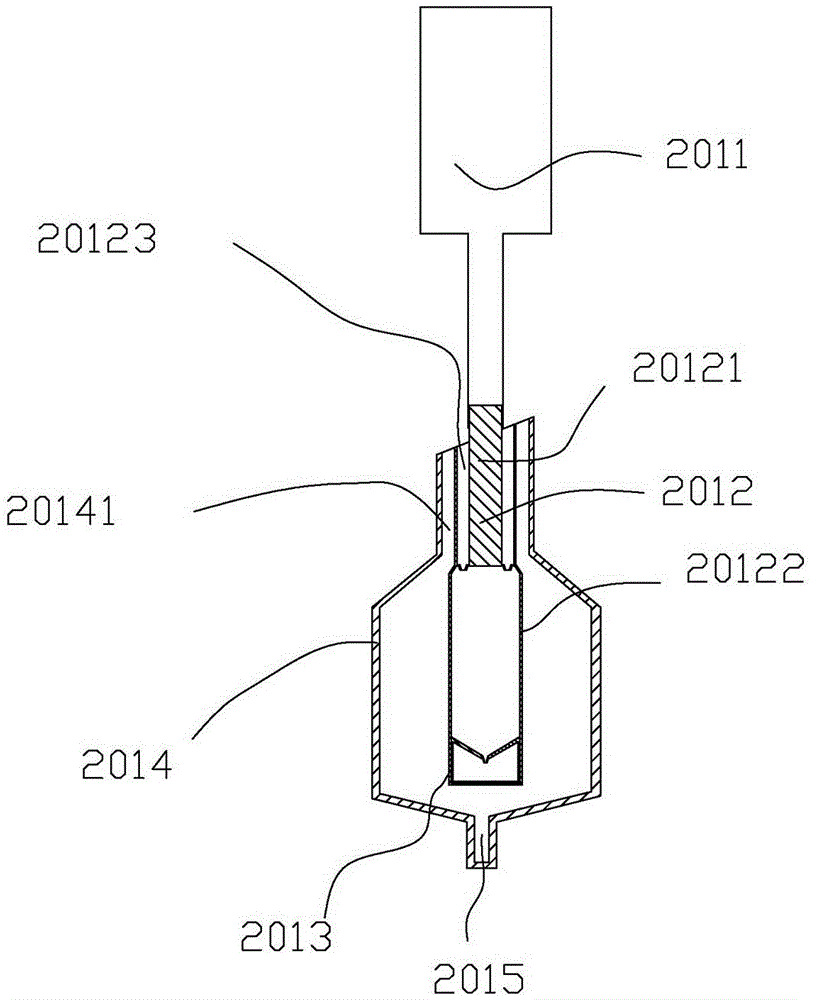

[0023] Example: figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a self-filtering reactor includes a reactor body 1, and also includes a negative pressure circulation filter device 2 arranged on the reactor body 1 for filtering raw materials, and the negative pressure circulation filter Device 2 comprises a first filter unit 201 and a second filter unit 202 connected to said first filter unit 201; said first filter unit 201 comprises a motor 2011 located above said reactor body 1, and said motor 2011 is connected with the rotating and shaking filter screen 2012, the impurity collection box 2013 located at the bottom of the rotating and shaking filter screen 2012, and the storage box for storing the rotating and shaking filter screen 2012 fixedly connected on the reactor body 1. The liquid temporary storage tank 2014 of the liquid and the bottom outlet 2015 arranged at the bottom of the liquid temporary storage tank 2014, the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com