Monolithic titanium oxide-aluminum oxide material and preparation method thereof

A technology of alumina and titanium oxide, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems that the product does not have a three-dimensional macroporous structure, and the environmental pollution of the discharge is serious, so as to eliminate Non-uniform pore size, increased specific surface area, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

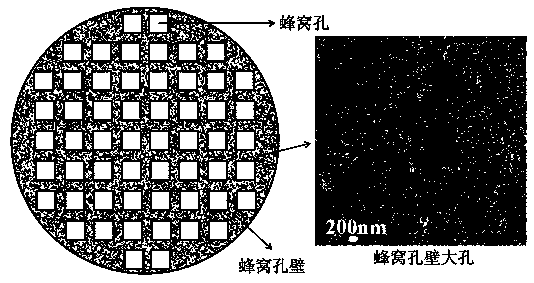

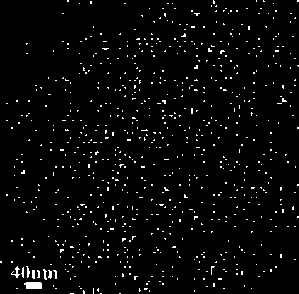

Image

Examples

Embodiment 1

[0040] (1) Preparation of titanium-containing aluminum sol: Boehmite powder, titanium dioxide ultrafine particles (average particle size 10nm) are mixed with distilled water to form a suspension, and hydrochloric acid is added dropwise under continuous stirring conditions to meet the acid / aluminum molar ratio of 0.07 After the dropwise addition, the temperature was raised to 85°C and refluxed for 5 hours to form a stable aluminum sol, and then a paste was formed by rotary evaporation (temperature 40°C, vacuum degree 100Pa).

[0041] (2) Mix water, absolute ethanol, aluminum chloride, polyethylene glycol, paste, and acetamide evenly at room temperature, and then add pyridine. The contents of each component of the mixture are by weight: water 22wt%, Ethanol 20wt%, aluminum chloride 22wt%, polyethylene glycol (viscosity average molecular weight 1 million) 1.0wt%, paste 5wt% (containing 20wt% titanium dioxide), acetamide 2wt%, pyridine 28%. After mixing evenly, cast it into the se...

Embodiment 2

[0044] Step (1) is the same as in Example 1.

[0045] (2) Mix water, absolute ethanol, aluminum chloride, polyethylene glycol, paste, and formamide at room temperature, and then add pyridine. The contents of each component of the mixture are by weight: water 24wt%, Ethanol 20wt%, aluminum chloride 22wt%, polyethylene glycol (viscosity average molecular weight 2 million) 1.0wt%, paste 3wt% (containing 25wt% titanium dioxide), formamide 3wt%, pyridine 27%. After mixing evenly, cast it into a plastic anti-honeycomb mold, continue to age at 70°C for 48 hours after gelation, soak the aged mixture in ethanol for 48 hours after demoulding, after soaking and remove the liquid phase, bake at 60°C Dry until the product no longer loses weight significantly, and then calcined at 650° C. for 6 hours to obtain a cylindrical monolithic titanium oxide-alumina composite oxide material.

[0046] The obtained monolithic alumina material has a total porosity of 74% and a specific surface area of...

Embodiment 3

[0048] Step (1) is the same as in Example 1, except that the particle size of the ultrafine titanium dioxide used is 15 nm.

[0049] (2) Mix water, absolute ethanol, aluminum chloride, polyethylene glycol, paste, N,N-dimethylformamide evenly at room temperature, and then add pyridine. The components of the mixture are by weight, and the content They are: water 22wt%, ethanol 20wt%, aluminum chloride 21wt%, polyethylene glycol (viscosity average molecular weight 2 million) 1.0wt%, paste 8wt% (containing 20wt% titanium dioxide), N, N-two Methylformamide 2wt%, pyridine 26%. After mixing evenly, cast it into a plastic anti-honeycomb mold, continue to age at 70°C for 48 hours after gelation, soak the aged mixture in ethanol for 48 hours after demoulding, after soaking and remove the liquid phase, bake at 60°C Dry until the product no longer loses weight significantly, and then calcined at 700° C. for 6 hours to obtain a cylindrical monolithic titanium oxide-alumina composite oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com