High impact toughness polycrystalline diamond carbide composite sheet and manufacturing method thereof

A technology of diamond composite sheet and polycrystalline diamond, which is applied to the method of using atmospheric pressure to chemically change substances, chemical instruments and methods, earth square drilling and mining, etc., which can solve the problems of insufficient improvement in the reduction of impact toughness of composite sheets, etc. , to achieve the effects of reducing residual internal stress, reducing metal phase loss, and improving sinterability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

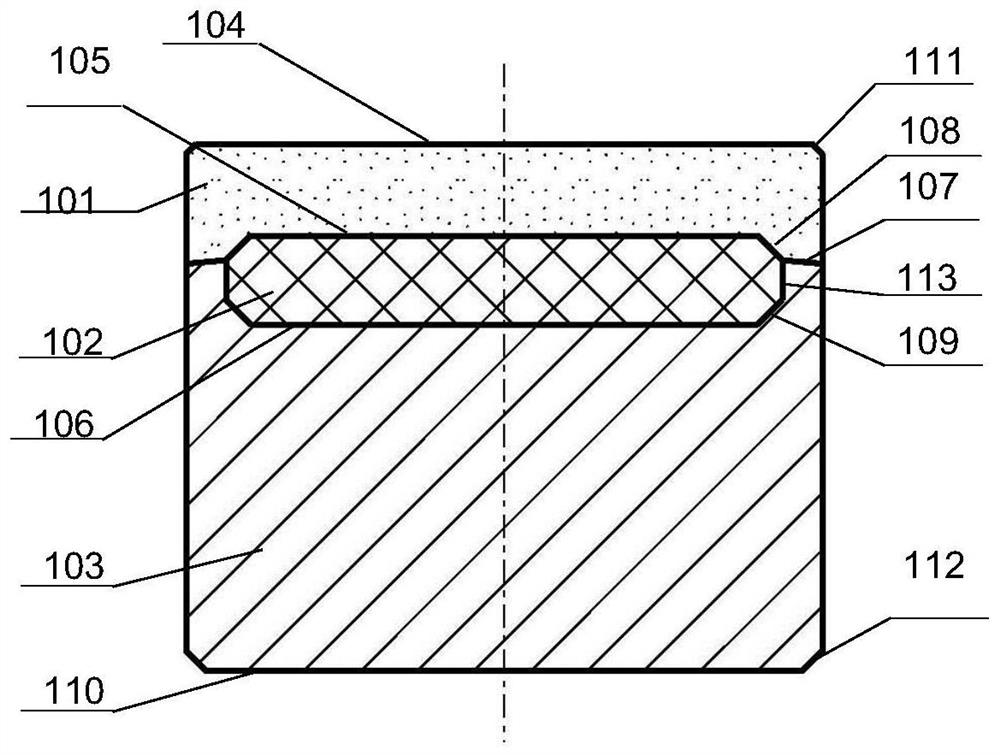

[0045] Such as figure 1 As shown, a polycrystalline diamond cemented carbide composite sheet with high impact resistance and toughness includes a diamond composite layer 101 , a cemented carbide substrate 103 and a polyhedral filler block 102 on top of the cemented carbide substrate 103 . Wherein, the polyhedral filling block 102 is provided with a circular top surface 105, a circular bottom surface 106 and side surfaces 113, the top surface edge has a chamfered surface 108 formed by chamfering, and the bottom surface edge has a chamfered surface 109 formed by chamfering. The top of the cemented carbide substrate 103 is provided with a groove complementary to the shape of the above-mentioned polyhedral filler block 102 , and the groove matches the bottom surface 106 of the polyhedron filler block 102 , the side surface 113 and the chamfered surface 109 on the edge of the bottom surface 106 . The combination of the annular inclined surface 107 on the top of the cemented carbide...

Embodiment 2

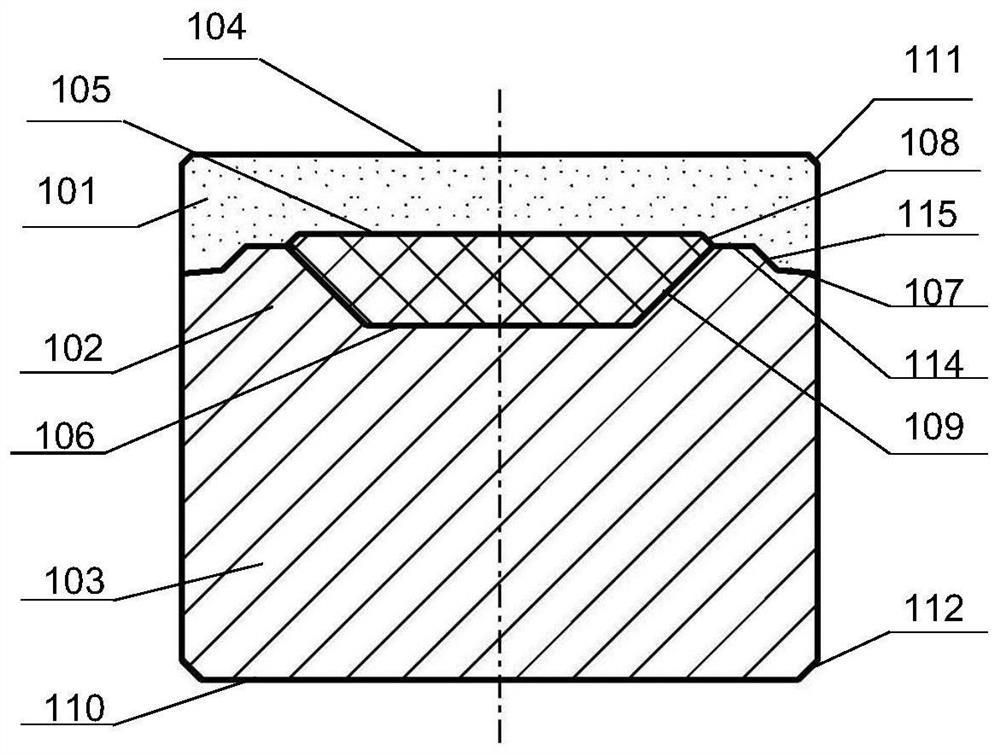

[0056] Such as figure 2 As shown, the difference between this embodiment and the first embodiment is that the shape of the polyhedron filling block 102 is different, and the polyhedron filling block 102 is also provided with a circular top surface and a circular bottom surface, and the edge of the circular top surface is chamfered. The formed chamfered surface 208 has a chamfered surface 109 formed by chamfering on the edge of the bottom surface, but the polyhedral filling block 102 has no side faces. Furthermore, the cemented carbide substrate 103 has different shapes, and the top of the cemented carbide substrate 103 is provided with a groove that is complementary to the shape of the polyhedron filling block 102, and the bottom surface 106 of the polyhedron filling block 102 and the chamfering surface 109 of the edge thereof are in phase with the groove. match. The annular inclined surface 107 on the top of the cemented carbide substrate 103, the raised conical side 115 an...

Embodiment 3

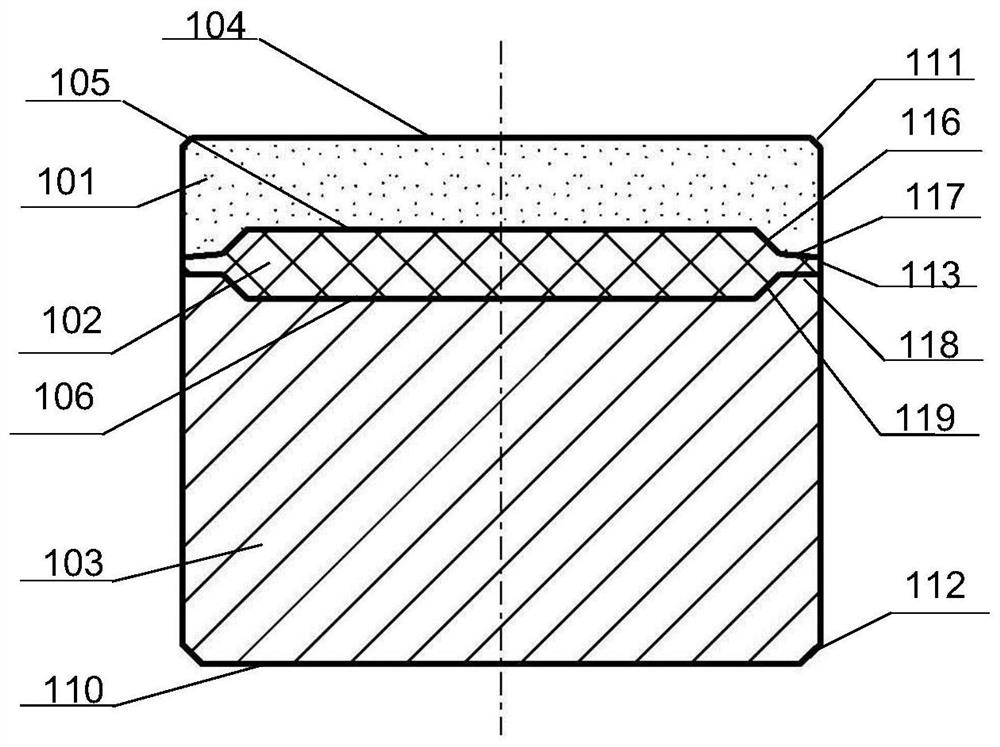

[0059] Such as image 3 As shown, the structure difference between the present embodiment and the first embodiment is that the polyhedron filling block 102 is provided with a circular top surface 105, a circular bottom surface 106, an upper conical side surface 116, a lower circular conical side surface 119, an annular upper bottom surface 117, an annular Lower bottom surface 118 and side surfaces 113 .

[0060] The top of the cemented carbide substrate 103 is provided with a groove complementary to the shape of the polyhedral filling block 102 , the groove coincides with the circular bottom 106 , the lower frustum side 119 and the annular bottom 118 of the polyhedral filling 102 . The annular upper bottom surface 117 of the polyhedral filling block 102, the upper circular frustum side surface 116 and the circular top surface 105 are combined to form a bonding interface with the diamond powder. The radial section of the diamond composite sheet is circular with a diameter of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com