Method for preparing nano-silica

A nano-silicon dioxide and silicon source technology, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of clogging and cleaning of microchannel reactor channels, and achieve uniform and controllable particle size and production efficiency. High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

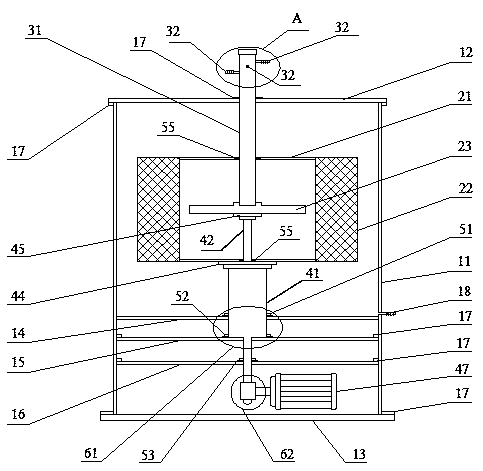

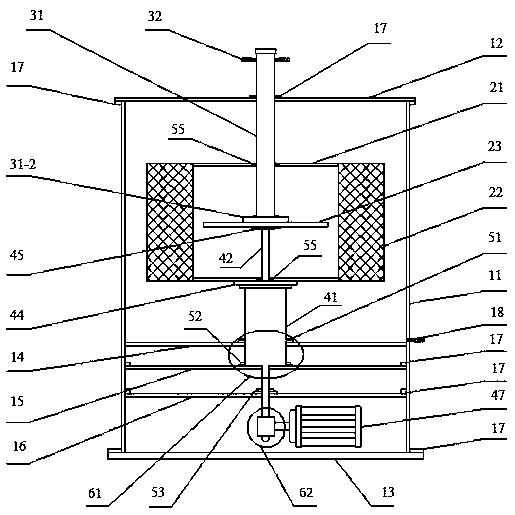

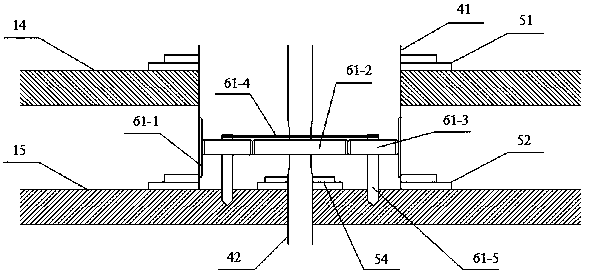

Image

Examples

Embodiment 1

[0052] Sodium silicate and sodium oleate were dissolved in deionized water to obtain solution A, wherein the mass concentration of sodium silicate was 15%, and the concentration of sodium oleate was 0.1mol / L; sodium oleate and excess ammonium sulfate were dissolved in deionized water In ionized water, take the solution part to obtain solution B with a sodium oleate concentration of 0.1mol / L; turn on the supergravity micro-reaction device, adjust the rotation speed of the micro-reaction plate to 1000rpm, and the rotation speed of the packing layer to 500rpm, wherein the size of the micro-reaction channel is 1 ~2mm; pump solution A and solution B into the supergravity micro-reaction device at a ratio of 1:3, and control the reaction temperature at 35°C; pump the precursor slurry obtained from the reaction into the high-pressure reactor, add After equal mass of deionized water, add a certain amount of polyacrylamide and hydrofluoric acid and stir evenly. The concentration of polya...

Embodiment 2

[0054] Prepare an ethanol solution with a tetraethyl tetrasilicate concentration of 3 mol / L and a hexadecyltrimethylammonium bromide concentration of 0.3 mol / L as solution A; add ammonia water dropwise to the mixture of deionized water and absolute ethanol Add cetyltrimethylammonium bromide and stir to obtain solution B afterward, wherein the concentration of ammoniacal liquor in solution B is 0.5mol / L, and cetyltrimethylammonium bromide concentration is 0.3mol / L, remove The volume ratio of ionized water to ethanol is 2:1; open the supergravity micro-reaction device, adjust the rotation speed of the micro-reaction plate to 1000rpm, and the rotation speed of the packing layer to 500rpm, wherein the size of the micro-reaction channel is 1.5mm; solution A and solution B Pump it into the supergravity micro-reaction device at a ratio of 1:2.5, and control the reaction temperature at 35°C; pump the precursor slurry obtained from the reaction into a high-pressure reactor, add deionize...

Embodiment 3

[0056] Dissolve sodium silicate and sodium dodecylbenzenesulfonate in deionized water to obtain solution A, wherein the mass concentration of sodium silicate is 20%, and the concentration of sodium dodecylbenzenesulfonate is 0.2mol / L; Sodium dodecylbenzenesulfonate concentration is the aqueous solution of 0.2mol / L, then add excess ammonium chloride and stir and take the supernatant to obtain solution B; open the supergravity micro-reaction device, adjust the rotating speed of the micro-reaction plate to 2000rpm, fill The rotation speed of the layer is 1500rpm, and the size of the micro-reaction channel is 0.5-1mm; the solution A and the solution B are pumped into the high-gravity micro-reaction device at a ratio of 1:3.5, and the reaction temperature is controlled at 35°C; The precursor slurry is pumped into the high-pressure reactor, after adding deionized water of equal mass, a certain amount of polyethylene glycol (400-2000) and hydrofluoric acid are added and stirred evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com