A kind of polydopamine film and its preparation method and application

一种聚多巴胺薄膜、反应的技术,应用在医用植入材料中的应用领域,能够解决腐蚀性、解聚和溶膜现象、负载难题等问题,达到提高安全性能、避免腐蚀作用、避免刺激和腐蚀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

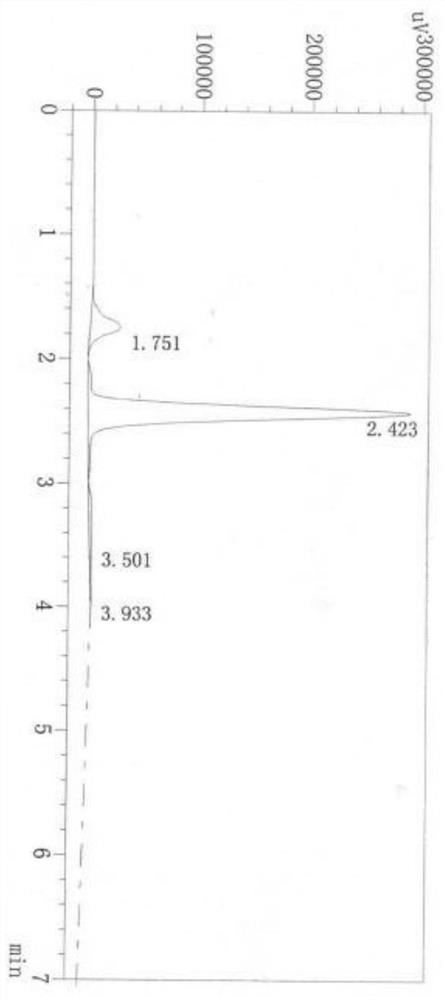

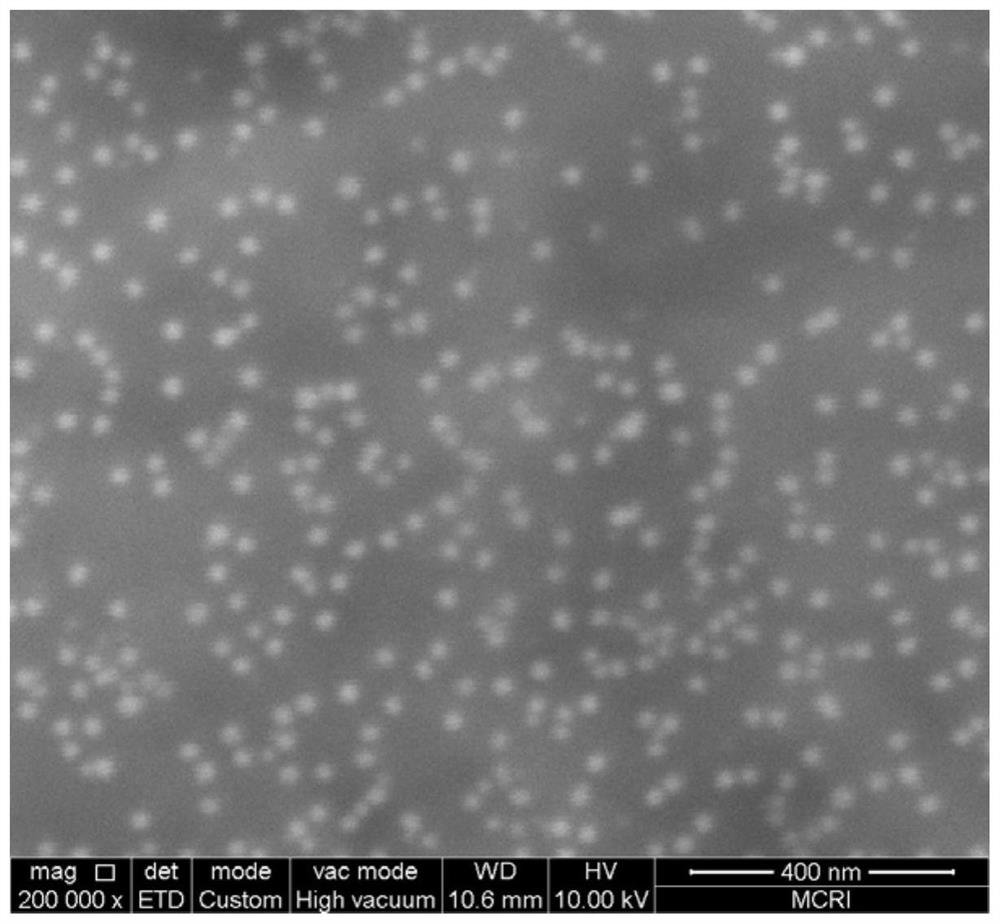

[0057] 1. Preparation of polydopamine coating:

[0058] 1.1 The cleaned pure titanium medical implant material is irradiated with ultraviolet rays for 1 hour, then soaked in Tris-HCL solution containing 2g / L dopamine monomer at pH 8.5, and then calcium peroxide with a final concentration of 10mg / L is added. Immediately put the reaction bottle containing the mixture into the body cavity of a temperature-controllable focusing microwave synthesizer, and react at a constant temperature of 25°C for 3 minutes, with a microwave power of 300W, and a dense polydopamine film can be obtained on the surface of the implant. Take it out and wash it repeatedly by ultrasonic, rinse it with deionized water, and dry it with nitrogen gas.

[0059] 1.2 does not repeat 1.1. The polydopamine film is a single layer.

[0060] 2. In Situ Synthesis of Silver Sulfadiazine on Conventional Polydopamine Films

[0061] 2.1 Put the material treated in 1.2 in a solution of sulfadiazine (20mmol / L) in sodium...

Embodiment 2

[0064] 1. Preparation of polydopamine coating:

[0065] 1.1 Irradiate the cleaned titanium alloy (TI-6AL-4V) medical implant material under ultraviolet light for 6 hours, then soak it in a pH7.1 Tri-HCL solution containing 1g / L dopamine monomer, and then add a final concentration of 20mg / L of calcium peroxide, immediately put the reaction bottle containing the mixture into the body cavity of the temperature-controllable focusing microwave synthesizer, react at a constant temperature of 65°C for 5 minutes, and the microwave power is 100W, and a A dense polydopamine film was taken out, washed repeatedly by ultrasonic waves, rinsed with deionized water, and dried with nitrogen.

[0066] 1.2 Repeat step 1.1 4 times. The final polydopamine film is 5 layers.

[0067] 2. In Situ Synthesis of Silver Sulfadiazine on Conventional Polydopamine Films

[0068] 2.1 Place the material treated in 1.2 in a solution of sulfadiazine (30mmol / L) in sodium hydroxide (45mmol / L), pH 8.7, so that ...

Embodiment 3

[0071] 1. Preparation of polydopamine coating:

[0072] 1.1 The cleaned titanium alloy (Ti-25nb-10ta-1zr-0.2fe) medical implant material was irradiated under ultraviolet light for 12 hours, and then soaked in a pH8.0 Tri-HCL solution containing 3g / L dopamine monomer, Calcium peroxide with a final concentration of 40 mg / L was then added, and the reaction bottle containing the mixture was immediately put into the body cavity of a temperature-controllable focusing microwave synthesizer, and reacted at a constant temperature of 50°C for 11 minutes, and the microwave power was 100W, and the plant was ready. A dense polydopamine film was obtained on the surface of the object, which was taken out and washed repeatedly with ultrasonic waves, rinsed with deionized water, and dried with nitrogen gas.

[0073] 1.2 Repeat step 1.1 9 times. The polydopamine film is 10 layers.

[0074]2. In Situ Synthesis of Silver Sulfadiazine on Conventional Polydopamine Films

[0075] 2.1 Put the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com