Polydopamine film as well as preparation method and application thereof

A polydopamine film and reaction technology, applied in the application field of medical implant materials, can solve problems such as corrosion, depolymerization and film dissolution, loading problems, etc., and achieve the effects of simplifying steps, promoting synthesis, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

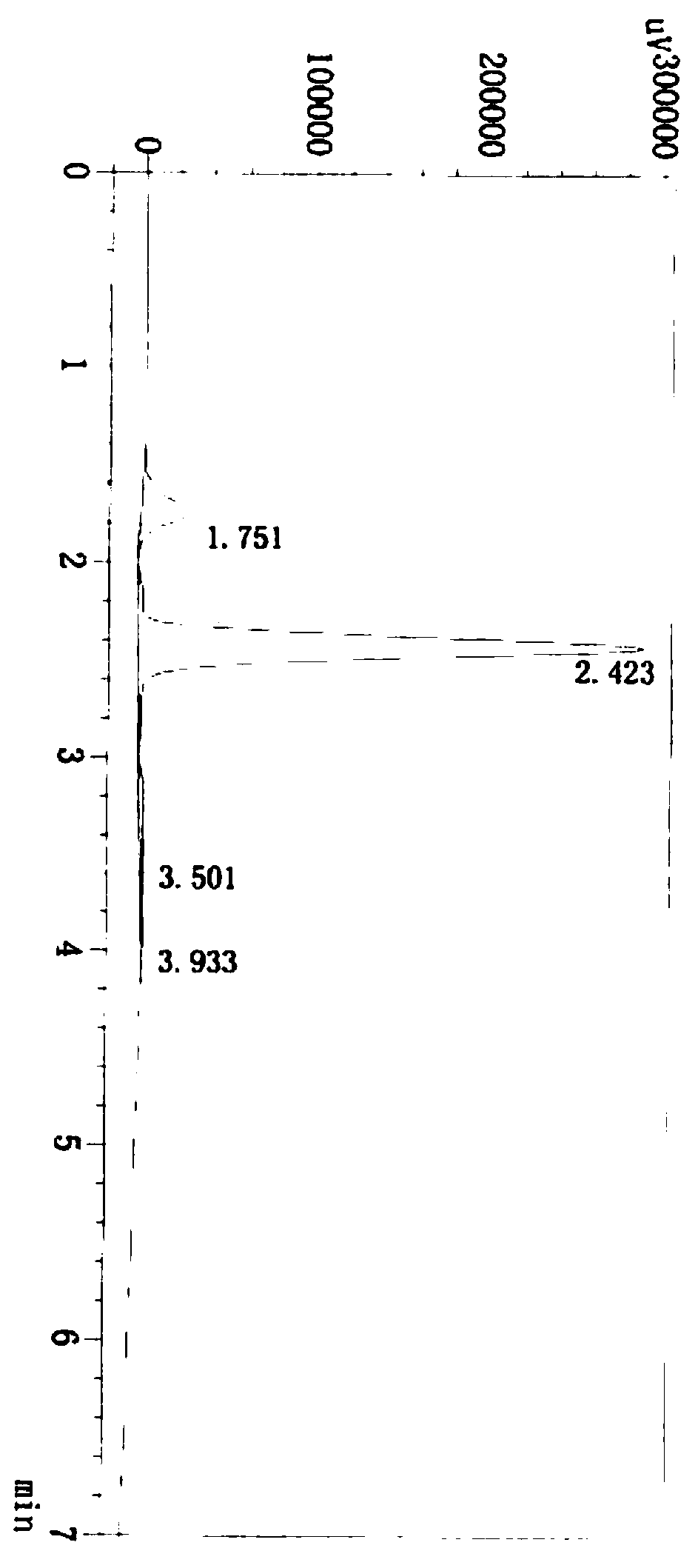

[0057] 1. Preparation of polydopamine coating:

[0058] 1.1 The cleaned pure titanium medical implant material is irradiated under ultraviolet light for 1 hour, then soaked in a pH 8.5 solution containing 2g / L dopamine monomer Tris-HCL, and then added with a final concentration of 10mg / L calcium peroxide, Immediately after putting the reaction flask containing the mixed solution into the body cavity of a temperature-controlled focused microwave synthesizer, react at a constant temperature of 25°C for 3 minutes with a microwave power of 300W, and a dense polydopamine film can be obtained on the surface of the implant. Take out and repeat ultrasonic washing and rinse with deionized water and dry with nitrogen.

[0059] 1.2 does not repeat 1.1. The polydopamine film is a single layer.

[0060] 2. In-situ synthesis of silver sulfadiazine on conventional polydopamine film

[0061] 2.1 Put the treated material in 1.2 in a solution of sulfadiazine (20mmol / L) in sodium hydroxide (20mmol / L),...

Embodiment 2

[0064] 1. Preparation of polydopamine coating:

[0065] 1.1 The cleaned titanium alloy (TI-6AL-4V) medical implant material is irradiated under ultraviolet light for 6 hours, then immersed in a pH 7.1 solution containing 1g / L dopamine monomer Tri-HCL, and then added to a final concentration of 20mg / L calcium peroxide, immediately put the reaction flask containing the mixture into the body cavity of the temperature-controlled focused microwave synthesizer, and react at 65°C for 5 minutes with a microwave power of 100W. The dense layer of polydopamine film is taken out and washed repeatedly with ultrasonic and rinsed with deionized water, and dried with nitrogen.

[0066] 1.2 Repeat step 1.1 4 times. Finally, the polydopamine film has 5 layers.

[0067] 2. In-situ synthesis of silver sulfadiazine on conventional polydopamine film

[0068] 2.1 Put the treated material in 1.2 in a solution of sulfadiazine (30mmol / L) in sodium hydroxide (45mmol / L), pH 8.7, so that the molar ratio of sul...

Embodiment 3

[0071] 1. Preparation of polydopamine coating:

[0072] 1.1 The cleaned titanium alloy (Ti-25nb-10ta-1zr-0.2fe) medical implant material is irradiated under ultraviolet light for 12 hours, and then immersed in a pH 8.0 Tri-HCL solution containing 3g / L dopamine monomer. Then add calcium peroxide with a final concentration of 40mg / L, and immediately put the reaction flask containing the mixed solution into the body cavity of the temperature-controlled focusing microwave synthesizer, and react at a constant temperature of 50°C for 11 minutes with a microwave power of 100W. A layer of dense polydopamine film is obtained on the surface of the object, which is taken out and washed repeatedly with ultrasonic and rinsed with deionized water and dried with nitrogen.

[0073] 1.2 Repeat step 1.1 9 times. The polydopamine film has 10 layers.

[0074] 2. In-situ synthesis of silver sulfadiazine on conventional polydopamine film

[0075] 2.1 Put the treated material in 1.2 in a solution of sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com