Single crystal thin film composite substrate and manufacturing method thereof

A single crystal thin film, composite substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as warping, affecting the efficiency of lithography process, electrodes, semiconductor performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

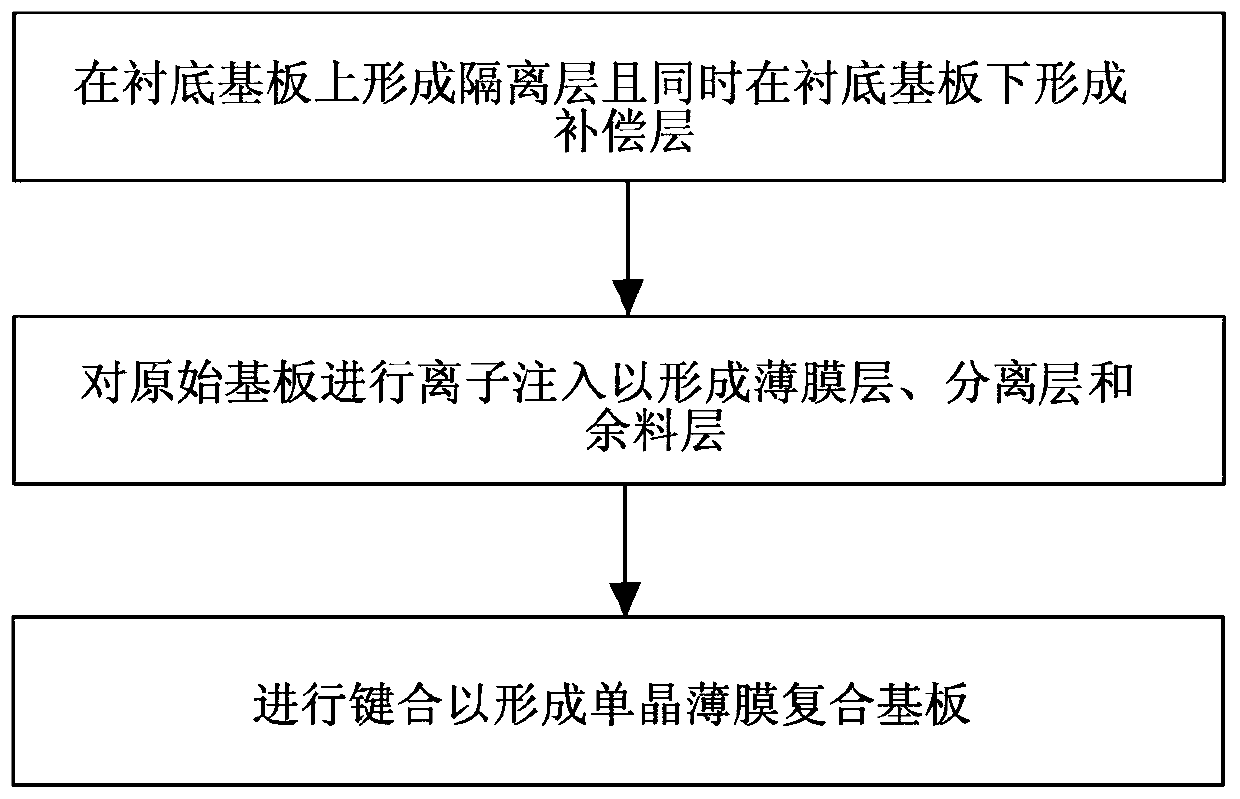

Method used

Image

Examples

Embodiment 1

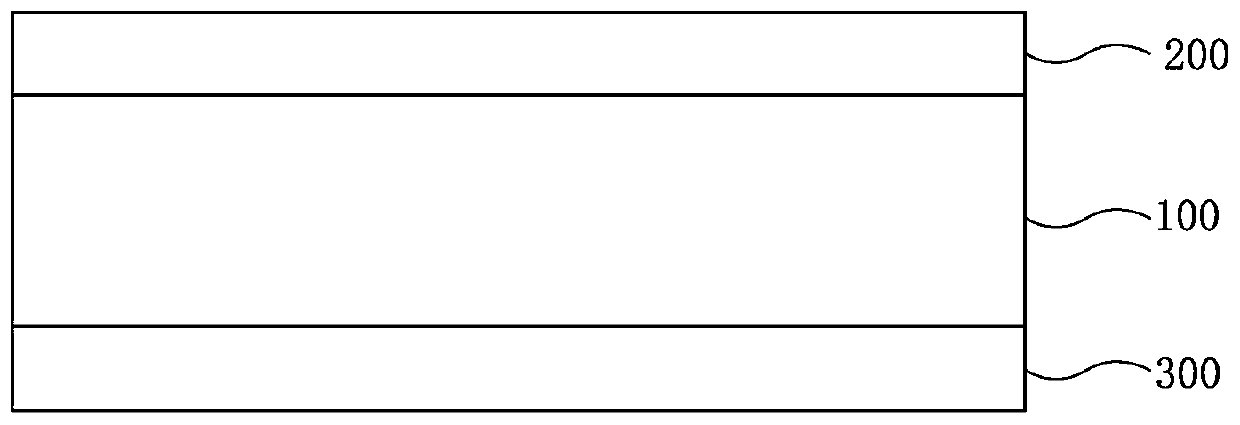

[0062] The base substrate is a single crystal lithium niobate wafer with a size of 3 inches and a thickness of 0.4 mm, and the lithium niobate wafer has a smooth surface. After the lithium niobate wafer is thoroughly cleaned, a silicon dioxide layer with a thickness of 2.7 μm is prepared on the upper and lower sides of the lithium niobate wafer by PECVD, and the silicon dioxide layer is chemically and mechanically polished to 2 μm and the surface roughness is less than 0.5nm.

[0063] The original substrate was a 3-inch lithium niobate wafer. Using ion implantation method, the implant dose of lithium niobate wafer is 4×10 16 ions / cm 2 the helium ion (He 1+), the energy of the helium ion is 200keV. After the ions are implanted into the lithium niobate wafer, a thin film layer, a separation layer and a residue layer are formed. At room temperature, the silicon dioxide layer on one surface of the single crystal lithium niobate wafer is bonded to the thin film layer of the li...

Embodiment 2

[0065] Substrate The substrate is a single crystal silicon wafer with a size of 3 inches and a thickness of 0.4 mm, and the single crystal silicon wafer has a smooth surface. After the single crystal silicon wafer is thoroughly cleaned, a silicon dioxide layer with a thickness of 2 μm and a surface roughness of less than 0.5 nm is prepared on the upper and lower sides of the single crystal silicon wafer by a thermal oxidation process.

[0066] The original substrate was a lithium niobate wafer measuring 3 inches. Using the ion implantation method, the implantation dose to the lithium niobate wafer is 4×10 16 ions / cm 2 Helium ions (He 1+ ), the energy of the helium ion is 200keV. After the ions are implanted into the lithium niobate wafer, a thin film layer, a separation layer and a residue layer are formed. At room temperature, the silicon dioxide layer on one surface of the single crystal silicon wafer is bonded to the thin film layer of the lithium niobate wafer to form ...

Embodiment 3

[0068] The substrate is a single crystal lithium niobate wafer with a size of 3 inches and a thickness of 0.4 mm, and the lithium niobate wafer has a smooth surface. After the lithium niobate wafer was thoroughly cleaned, a silicon nitride layer with a thickness of 2.7 μm was prepared on the upper and lower sides of the lithium niobate wafer by PECVD, and the silicon nitride layer was chemically and mechanically polished to 2 μm and the surface roughness was less than 0.5nm.

[0069] The original substrate was a lithium niobate wafer measuring 3 inches. Using the ion implantation method, the implantation dose to the lithium niobate wafer is 4×10 16 ions / cm 2 Helium ions (He 1+ ), the energy of the helium ion is 200keV. After the ions are implanted into the lithium niobate wafer, a thin film layer, a separation layer and a residue layer are formed. At room temperature, the silicon nitride layer on one surface of the single crystal lithium niobate wafer is bonded to the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com