Combined treatment method of electroplating mixed wastewater

一种混合废水、综合处理的技术,应用在冶金废水处理、多阶段水处理、水/污水处理等方向,能够解决废水成分复杂、处理结果达标、困难等问题,达到好市场应用前景、处理成本低、降低COD的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: process the electroplating mixed wastewater containing cyanide

[0071] Electroplating mixed wastewater includes: cyanide copper plating wastewater, cyanide copper-zinc alloy electroplating wastewater, gun black tin-nickel alloy electroplating wastewater, pyrophosphate copper plating wastewater, alkaline zinc-nickel alloy electroplating wastewater, trivalent chromium chrome plating wastewater, trivalent Chromium passivation wastewater, hexavalent chromium passivation wastewater, copper plating, bright nickel plating, potassium chloride zinc plating, cyanide-free alkaline zinc plating, hexavalent chromium plating and other electroplating wastewater, pre-treatment degreasing wastewater, and pickling waste water. Excluding electroless nickel plating wastewater and electroless copper plating wastewater.

[0072] Step one, breaking cyanide

[0073] Transfer the electroplating mixed wastewater from the electroplating wastewater regulating tank to the primary o...

Embodiment 2

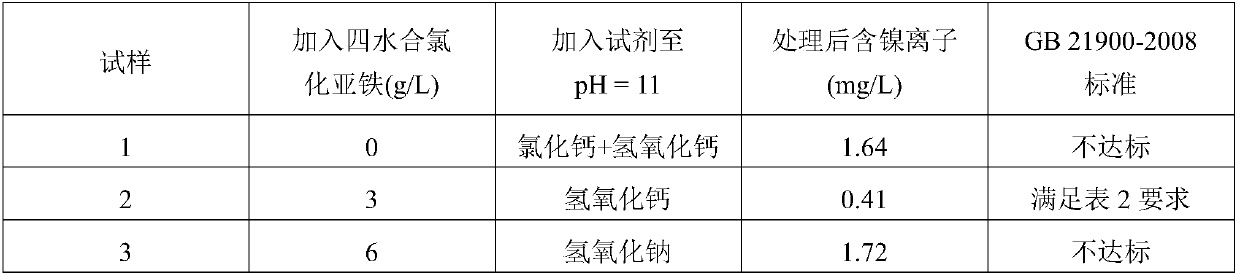

[0088] Embodiment 2: process the electroplating mixed wastewater containing electroless plating wastewater

[0089] Electroplating mixed wastewater includes: cyanide copper plating wastewater, cyanide copper-zinc alloy electroplating wastewater, gun black tin-nickel alloy electroplating wastewater, pyrophosphate copper plating wastewater, alkaline zinc-nickel alloy electroplating wastewater, trivalent chromium chrome plating wastewater, trivalent Chromium passivation wastewater, hexavalent chromium passivation wastewater, acid copper plating, bright nickel plating, potassium chloride zinc plating, cyanide-free alkaline zinc plating, hexavalent chromium plating and other electroplating wastewater, electroless nickel plating wastewater, electroless copper plating wastewater , pre-treatment degreasing wastewater, and pickling wastewater.

[0090] Step 1, oxidizing cyanide, and electroless plating complexing agent and reducing agent

[0091] Transfer the electroplating mixed wast...

Embodiment 3

[0105] Embodiment 3: Treatment does not contain the electroplating mixed wastewater of cyanide and electroless plating wastewater

[0106] Electroplating wastewater includes: pyrophosphate copper plating wastewater, electroplating alkaline zinc-nickel alloy wastewater, trivalent chromium plating wastewater, trivalent chromium passivation wastewater, hexavalent chromium passivation wastewater, acid copper plating, bright nickel plating, chloride Potassium galvanizing, cyanide-free alkaline galvanizing, hexavalent chromium plating and other electroplating wastewater, pre-treatment degreasing wastewater, and pickling wastewater.

[0107] Step 1. Oxidation of organic matter such as electroplating additives

[0108] Transfer the electroplating mixed wastewater from the electroplating wastewater regulating tank to the primary oxidation tank, stir the pool liquid with a mixer, add lime emulsion to adjust the pH of the wastewater to 10.5-12, and add an oxidant to oxidize for 60 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com