Preparation method and application of tin-lead binary perovskite thin film growing in preferred orientation mode

A preferred orientation, perovskite technology, applied in electrical components, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of destroying the three-dimensional perovskite structure, limiting perovskite, poor photoelectric properties of thin films, etc. The effect is sufficient to enhance the photoelectric properties and improve the surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

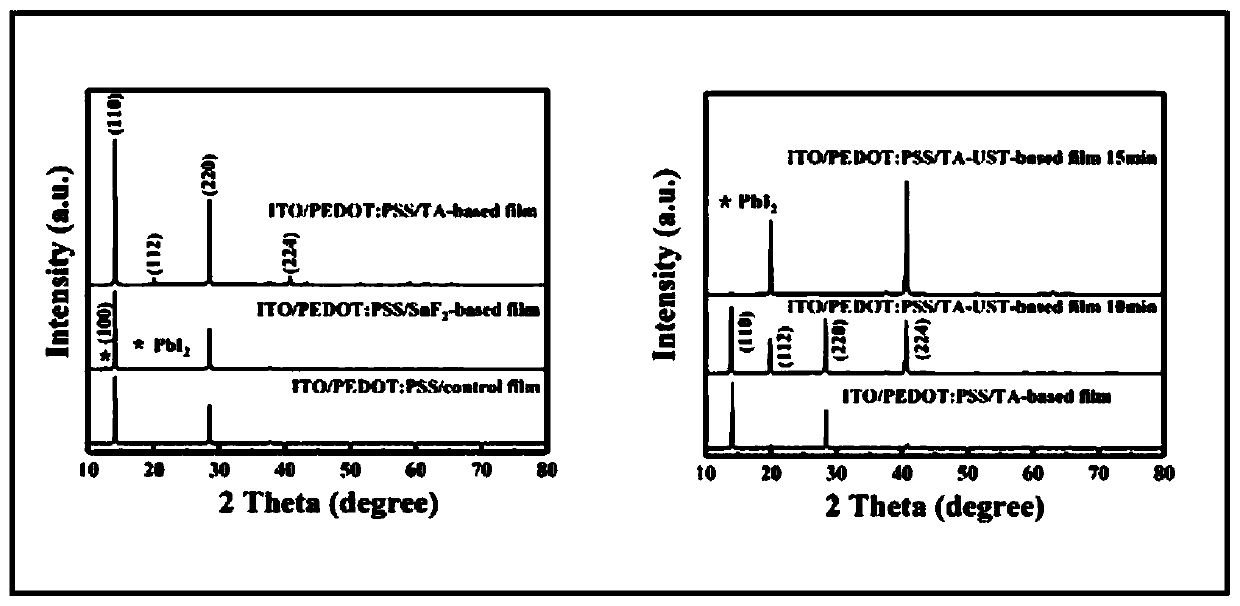

[0023] Specific embodiments of the present invention will be described in detail below with reference to the drawings.

[0024] A method for preparing a tin-lead binary perovskite film grown in a preferred orientation, the method comprising the following steps:

[0025] 1. Preparation of base material PEDOT:PSS: The clean ITO transparent conductive glass is treated with ultraviolet ozone for 20 minutes to improve its surface wettability and remove functional groups such as -OH on the surface. After the ITO is cooled to room temperature, 80μLPEDOT:PSS (AI4083) The original solution was dropped on the ITO surface and allowed to stand for 5-15 seconds, then spin-coated at a low speed of 500 rpm for 10 s, and processed at a high speed of 4000 rpm for 60 s. Then the material was heated on a scorching table at 140°C for 10 minutes. The prepared PEDOT:PSS film was subjected to ultraviolet ozone treatment for 20 minutes, cooled to room temperature, and moved to a glove box for later use.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com