Polycrystalline silicon ingot and casting method thereof

A technology of polycrystalline silicon ingots and silicon liquid, which is applied in the field of solar cells to achieve the effects of reducing production costs, reducing energy consumption, and high yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

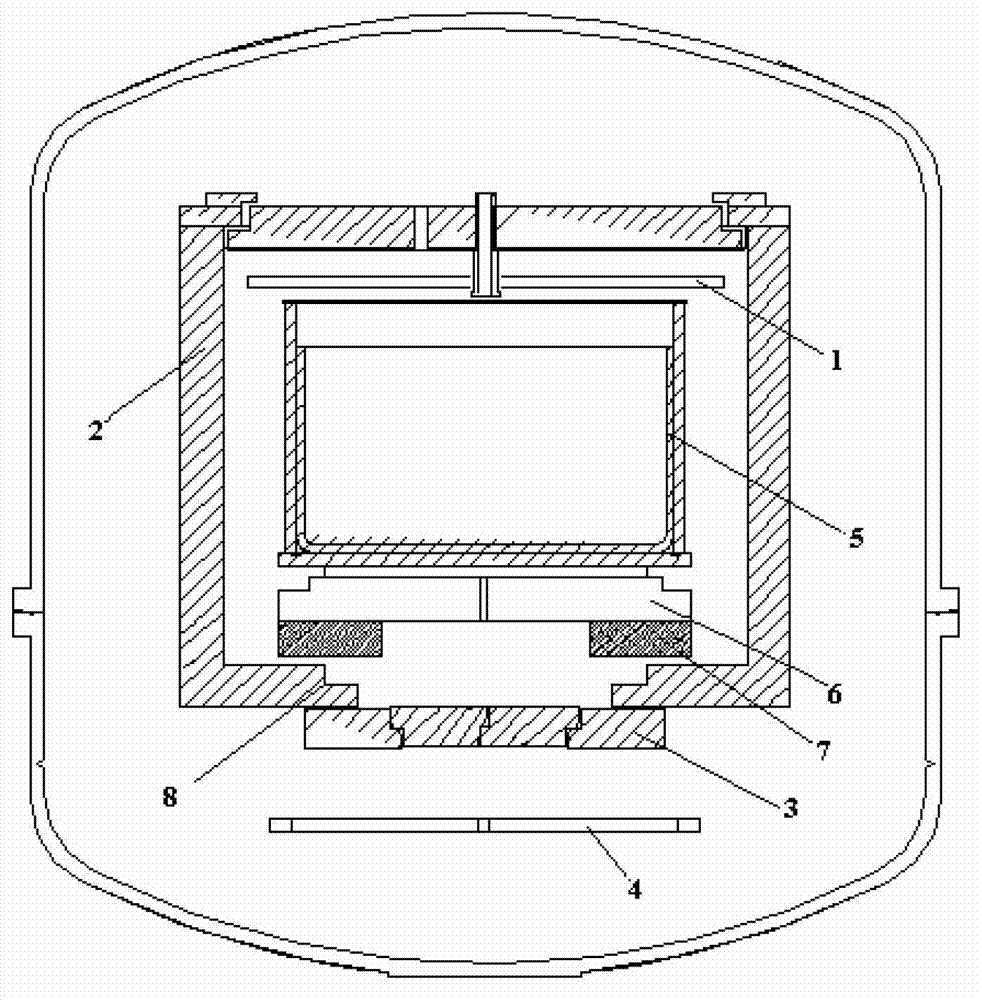

[0042] This embodiment provides a polysilicon ingot furnace, such as figure 2 As shown, the ingot casting furnace only has a top heater 1, which is characterized in that the ingot casting furnace includes a heat insulation layer 2, a water-cooled copper plate 4 located below the louver 3, a crucible 5 located inside the heat insulation layer 2, and a The heat dissipation platform 6 at the bottom of the crucible 5, and the thermal insulation bottom plate 7 arranged on the periphery of the bottom of the heat dissipation platform 6 and inside the heat insulation layer 2, the thermal insulation bottom plate 7 is directly in contact with the bottom of the heat dissipation platform 6; wherein the heat insulation The bottom of layer 2 has a louver 3 comprising a plurality of louvers, each openable to an angle of 90°;

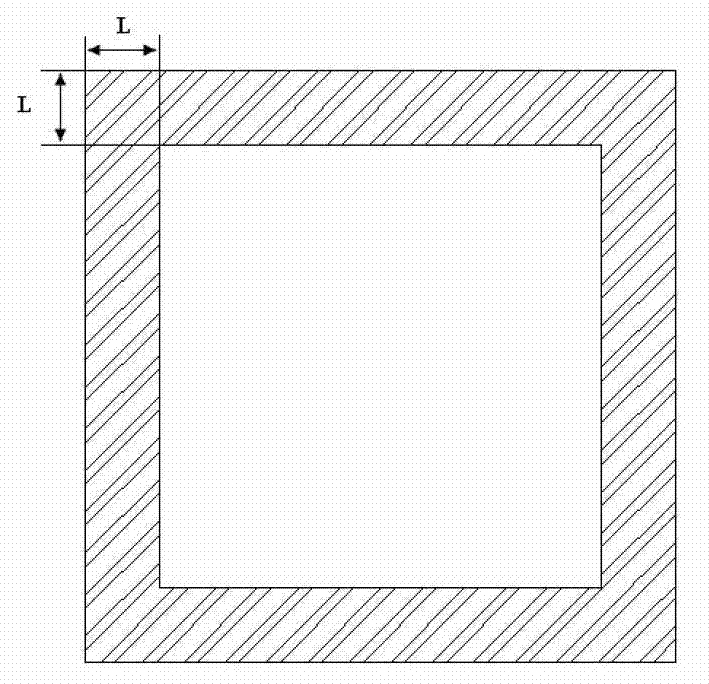

[0043] Wherein, the shape of the thermal insulation bottom plate 7 arranged on the periphery of the bottom of the heat dissipation platform 6 and inside the heat insula...

Embodiment 2

[0049] This embodiment provides a polysilicon ingot casting method, using the polysilicon ingot furnace provided in Example 1, the specific process is as follows Figure 4 shown, including:

[0050] Step 401: Load the silicon material into the crucible, and heat the silicon material to a molten state.

[0051] After loading the silicon material in the crucible, close the insulation layer, and use the top heater to heat the silicon material in the crucible until the silicon material is in a molten state. In order to melt all the silicon material in the crucible and make the impurities in the silicon liquid more volatile, it is necessary to keep the top of the crucible at a high temperature, and the temperature of the silicon liquid surface is higher than the melting point of the silicon liquid at 1420°C.

[0052] Step 402: Reduce the power of the heater at the top of the polysilicon ingot furnace, and at the same time gradually open the louvers to an angle of 25°-35° to lower ...

Embodiment 3

[0063] This embodiment discloses a polysilicon ingot produced by the methods of the above embodiments. Impurity residues and dark spots around the polycrystalline silicon ingot are significantly reduced, even without impurity residues and dark spots. The infrared flaw detection scan of the polycrystalline silicon ingot is shown in Figure 5 As shown, the quality of the polycrystalline silicon ingot is good and the production rate is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com