Method for measuring content of tin in crude lead

A determination method, crude lead technology, applied in the preparation of test samples, thermal excitation analysis, material excitation analysis, etc., can solve the problems of difficult device fabrication, difficult operation, high color temperature and condition requirements of photometric method, and achieve Effects of increasing accuracy, adding correction steps, and widening the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Weigh m as 4.9970g (accurate to 0.001) sample and measure according to the above method;

[0075] In Step 1, add 130 mL of dissolving acid, heat and dissolve on a hot plate at 220°C, add 97.5 mL of hydrochloric acid with a density ρ of 1.19 g / mL and 3 mL of potassium sodium tartrate with a concentration of 200 g / L,

[0076] Wash the original beaker 3 times and the filter paper 3 times with aqua regia with a mass concentration of 1% after the filtration is completed in step 2;

[0077] In step 3, put the zirconium crucible into the muffle furnace and raise it from low temperature to 650°C for ashing. After the ashing is complete, take it out and cool it, add 2g of sodium peroxide, cover with 0.5g of sodium peroxide, and put it in the muffle furnace at Melt at 680°C for 10 minutes, take it out and cool to room temperature;

[0078] Add 50mL water in step 4, add 10mL hydrochloric acid and 5mL potassium sodium tartrate;

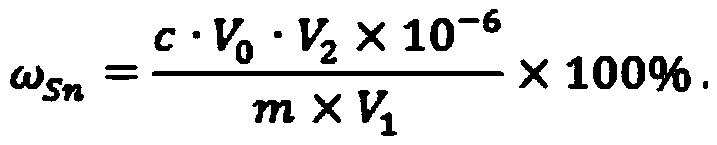

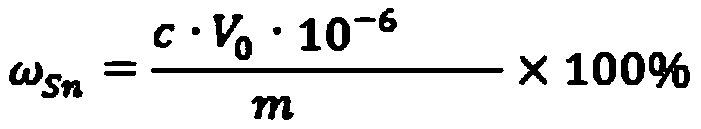

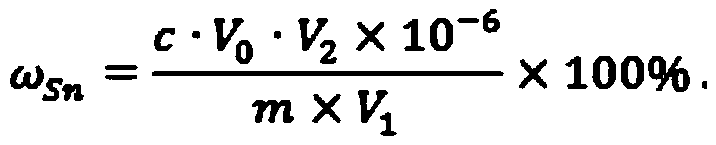

[0079] In step 5, the mass fraction range of tin i...

Embodiment 2

[0083] Weigh m as 4.9980g (accurate to 0.001) sample and measure it according to the above method;

[0084] In step 1, add 150 mL of dissolving acid, heat and dissolve on a hot plate at 250°C, add 97.5 mL of hydrochloric acid with a density ρ of 1.19 g / mL and 4 mL of potassium sodium tartrate with a concentration of 200 g / L,

[0085] After the filtration in step 2 is completed, wash the original beaker 3 times and the filter paper 3 times with aqua regia with a mass concentration of 1.5% respectively;

[0086] In step 3, put the zirconium crucible into the muffle furnace and raise it from low temperature to 700°C for ashing. After the ashing is complete, take it out and cool it, add 3g of sodium peroxide, cover with 1g of sodium peroxide, and put it in the muffle furnace at 700°C Melt at ℃ for 15 minutes, take out and cool to room temperature;

[0087] Add 60mL water in step 4, add 15mL hydrochloric acid and 6mL potassium sodium tartrate;

[0088] The mass fraction range of ...

Embodiment 3

[0092] Weigh m as 4.9990g (accurate to 0.001) sample and measure it according to the above method;

[0093] In step 1, 140 mL of dissolving acid was added, heated and dissolved on a hot plate at 250°C, 97.5 mL of hydrochloric acid with a density ρ of 1.19 g / mL and 5 mL of potassium sodium tartrate with a concentration of 200 g / L were added,

[0094] Wash the original beaker 3 times and the filter paper 3 times with aqua regia with a mass concentration of 1.2% after the completion of the filtration in step 2;

[0095] In step 3, put the zirconium crucible into the muffle furnace and raise it from low temperature to 700°C for ashing. After the ashing is complete, take it out and cool it, add 2.5g of sodium peroxide, cover with 0.8g of sodium peroxide, and put it into the muffle furnace Melt at 700°C for 15 minutes, take out and cool to room temperature;

[0096] Add 50mL water in step 4, add 12mL hydrochloric acid and 5.5mL potassium sodium tartrate;

[0097] The mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com