Enamel color material, preparation method thereof, and application in porcelain body painting enamel cultural relic repair

An enamel and color material technology, applied in the field of cultural relics restoration, can solve the problems of poor pigment dispersion, inability to use ancient ceramic restoration materials, etc., and achieve the effects of bright enamel color and luster, favorable for popularization and use, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Repair the black material and yellow stamen part of an enamel ancient porcelain plate with a black background.

[0041] (1) Preparation of black enamel pigment:

[0042] 1) Weigh the following raw materials and the mass parts of each raw material: 41 parts lead silicate, 28 parts quartz, 10 parts anhydrous boric acid, 2.5 parts bismuth trioxide, 13 parts potassium nitrate, 2 parts calcite, 9.5 parts iron oxide , 3.5 parts of manganese oxide, 0.5 parts of cobalt oxide, 0.06 parts of copper oxide;

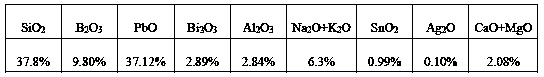

[0043] Table 1 shows the main chemical components of black enamel pigment and the mass percentage of each chemical component:

[0044]

[0045] 2) Mix the weighed raw materials, put them in a ceramic mortar and grind them to a 30-mesh sieve, and then place them in an alumina crucible with a lid;

[0046] 3) Place the open lid of the alumina crucible with a lid in the frit furnace. The frit furnace is evenly heated to 650℃ at a heating rate of 10℃ / min, then the lid of the alu...

Embodiment 2

[0057] Example 2: Repair the blue painted part of the painted enamel purple sand pot.

[0058] (1) Preparation of emerald blue enamel pigment:

[0059] 1) Weigh the following parts by mass: 62 parts of lead silicate, 33 parts of quartz, 11 parts of anhydrous boric acid, 3 parts of bismuth trioxide, 15 parts of potassium nitrate, 2.4 parts of cobalt oxide, 2 parts calcite, 4.5 parts iron oxide;

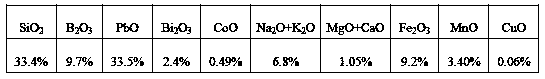

[0060] Table 3 shows the main chemical components of emerald blue enamel pigment and the mass percentage of each chemical component:

[0061]

[0062] 2) Put the weighed mixture of raw materials into a ceramic mortar and grind it to a 30-mesh sieve and pass it twice, then place it in an alumina crucible with a lid;

[0063] 3) Put the alumina crucible with lid in the frit furnace, open the lid of the alumina crucible, and evenly heat the frit furnace to 650°C at a heating rate of 10°C / min, then close the lid of the alumina crucible and continue heating To the maximum melting temperature of 125...

Embodiment 3

[0068] Example 3: Making carmine enamel porcelain.

[0069] (1) Preparation of carmine red enamel pigment:

[0070] 1) Combine 53 parts of lead silicate, 34 parts of quartz, 12 parts of anhydrous boric acid, 14 parts of potassium nitrate, 3.5 parts of bismuth trioxide, 0.12 parts of silver oxide, 1.2 parts of tin oxide, 8 parts of calcined kaolin, and 4.5 parts of calcite. Weigh the ingredients;

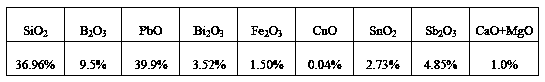

[0071] Table 4 shows the main chemical components of carmine enamel pigment and the mass percentage of each component:

[0072]

[0073] 2) Mix the weighed raw materials, add them to a ceramic mortar, grind them evenly, add a gold chloride solution containing 0.08% gold oxide, and stir evenly, 0.08% by mass in the gold chloride solution containing 0.08% gold oxide Is the mass percentage of the entire formula;

[0074] 3) Pour into a stainless steel pan, rinse the mortar with distilled water for 2-3 times, pour the rinsed solution into the stainless steel pan, then dry the materials in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com