Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, instruments, optics, etc., can solve the problems of lower yield and poor sealant leveling, and achieve improved yield and better sealant leveling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0171]

[0172] The preparation method of the liquid crystal alignment agent of the present invention is not particularly limited, and can be prepared by a general mixing method. For example, first add the solvent (B) to the polymer (A) prepared in the above manner at a temperature of 0°C to 200°C, and optionally add the additive (C), and finally continue with the stirring device Stir until dissolved. In addition, it is more preferable to add the solvent (B) at a temperature of 20°C to 60°C.

[0173]

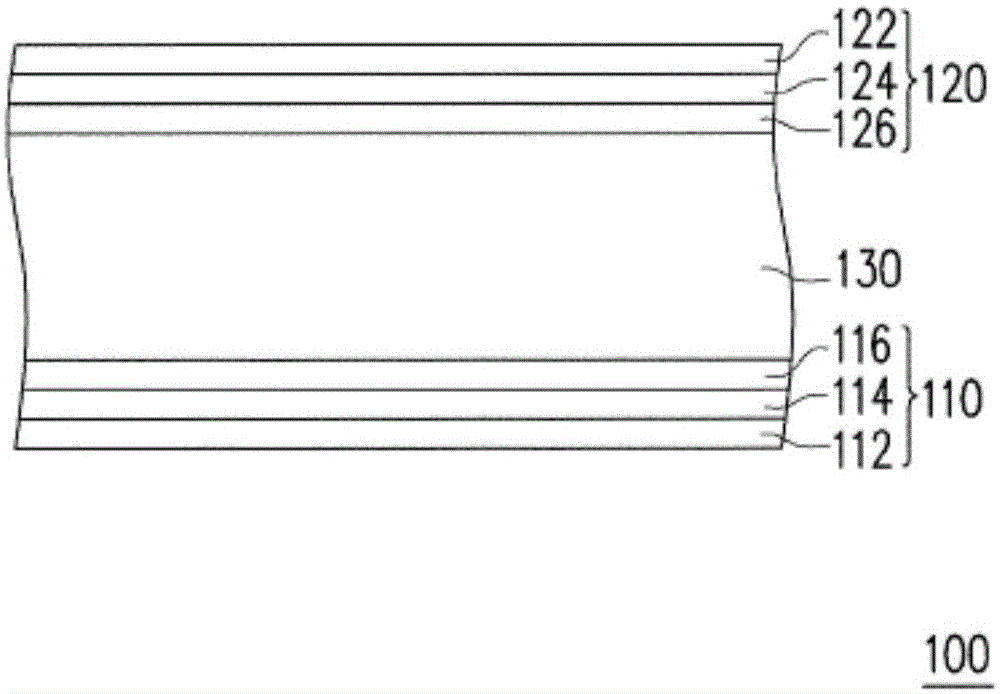

[0174] The method for forming a liquid crystal alignment film of the present invention includes the following steps: first, the liquid crystal alignment agent prepared above is coated by a roll coating method, a spin coating method, a printing method, an ink-jet method, etc. A pre-coating layer is formed on the surface of the substrate; then, the pre-coating layer is subjected to pre-bake treatment, post-bake treatment, and alignment treatment.

[0175] The purpose of the pre-bakin...

Synthetic example

[0196] The following describes the synthesis example A-1-1 to the synthesis example A-1-5 of the polymer (A), the synthesis example A-2-1 to the synthesis example A-2-10 and the comparative synthesis example A-3-1 to the comparison Synthesis Example A-3-6:

Synthetic example A-1-1

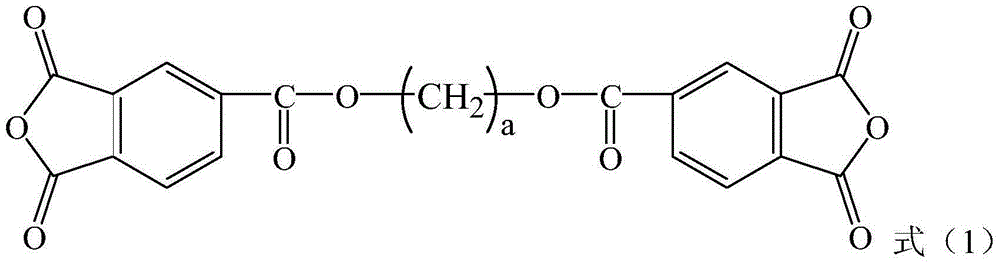

[0198] A nitrogen inlet, a stirrer, a condenser, and a thermometer were set on a four-necked flask with a volume of 500 ml, and nitrogen was introduced. Then, in a four-necked flask, 1.41 g (0.005 mol) of the diamine compound represented by formula (2-2) (abbreviated as b-1-1), 8.92 g (0.045 mol) of 4,4'- Diaminodiphenylmethane (abbreviated as b-2-1) and 80 grams of N-methyl-2-pyrrolidone (abbreviated as NMP) were stirred at room temperature until dissolved. Then, 41.03 grams (0.01 moles) of ethylene glycol bis(trimellitic anhydride) (abbreviated as a-1-1) and 8.96 grams (0.04 moles) of 2,3,5-tricarboxycyclopentylacetic dianhydride (abbreviated as It is a-2-1) and 20 grams of NMP, and reacted at room temperature for 2 hours. After the completion of the reaction, the reaction solution was poured into 1500 ml of water to precipitate the polymer. Then, the obtained polymer was filtered, washed with methanol and filtered three times, placed in a vacuum oven, and dried at a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com