100% biodegradable garbage bag with traceable two-dimensional code identifier and production method

A two-dimensional code, all-biological technology, applied in the field of full-biological 100% fully degradable garbage bags and preparation, can solve the problems of garbage recycling and sorting and processing difficulties, and achieve excellent environmental protection characteristics, reduce environmental pollution, and good tensile properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0042] Preparation Example 1: Add distilled water to cornstarch to prepare a cornstarch solution. The mass ratio of cornstarch to distilled water is 1:3. Stir and feed nitrogen. Stir in a water bath at 85°C for 30min, cool to 34°C, and Under the protection of nitrogen, add methyl acrylate with a concentration of 1120mol / L, stir for 5min, then add a solution of cerium ammonium nitrate with a concentration of 315×10-3mol / L, react at 34°C for 310-315h, and precipitate the product with absolute ethanol , washed three times with distilled water, dried by centrifugation and then dried to constant weight in a vacuum oven at 60°C.

preparation example 2-4

[0044] Rosin-modified phenolic resin in Preparation Example 2-4 is selected from the rosin-modified phenolic resin sold by Shanghai Nanke Electronic Trading Co., Ltd. with the brand name PR-12603, and the epoxy soybean oil is selected from the model sold by Guangzhou Zhongye Chemical Co., Ltd. It is the epoxy soybean oil of ESO, and black pigment is selected from the black pigment that the article number that Shenzhen Guanghong Plastic Pigment Co., Ltd. sells is 675, and nano-titanium dioxide is selected from the model that Anhui Xuancheng Jingrui New Material Co., Ltd. sells and is VK-T06S Nano-titanium dioxide, white peak wax is selected from Dongguang County Yilong Wax Products Factory, the brand is 62 # The white peak wax, chitosan is selected from the chitosan of item number 102 sold by Jiangsu Fushengde Biological Engineering Co., Ltd.

preparation example 2

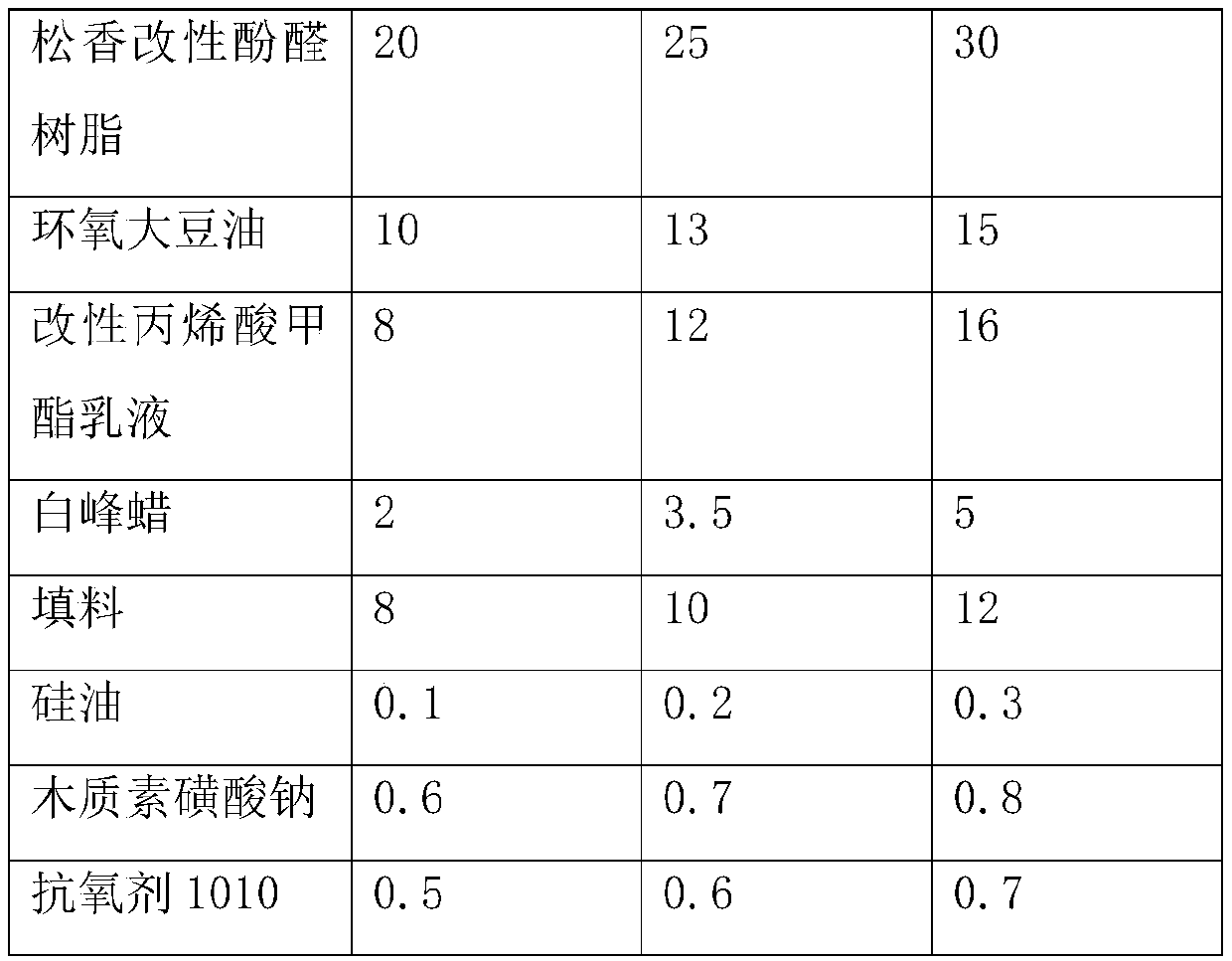

[0045] Preparation Example 2: (1) According to the raw material ratio in Table 1, heat 20kg rosin-modified phenolic resin, 10kg epoxy soybean oil and 8kg modified methyl acrylate emulsion to 200°C, stir for 2 hours, and add 0.5kg antioxidant Agent 1010, 0.1kg silicone oil and 8kg filler, stir and cool down to 50°C, let stand for 3h, and solidify at 30°C for 5h, the modified methyl acrylate emulsion is made from Preparation Example 1, and the mass ratio of the filler is 1:0.5: Made of 0.3 nanometer titanium dioxide, chitosan and calcium carbonate;

[0046] (2) Mix the product obtained in step (1) with 10 kg of pigment, 2 kg of white peak wax and 0.6 kg of sodium lignosulfonate, stir and disperse for 40 minutes, mix well and grind to a particle size of 10 μm to obtain soybean ink, the pigment is black.

[0047] The raw material ratio of soybean ink in table 1 preparation example 2-4

[0048]

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com