Graphene aluminum-based composite powder used for laser deposition manufacturing, and preparation method and application thereof

A laser deposition, aluminum-based composite technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of difficult molding, long printing time, difficult processing, etc., to achieve improved sample performance, interface Good combination, good interface combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

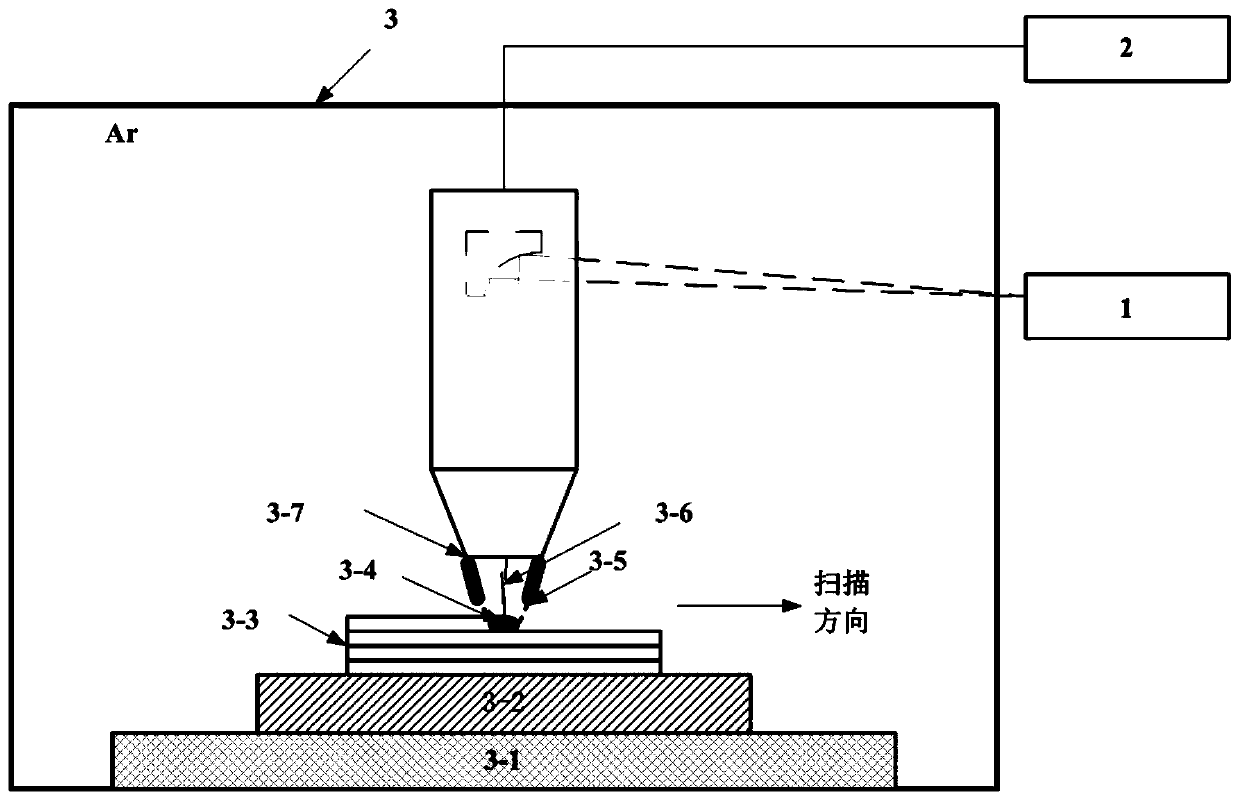

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for a graphene-aluminum-based composite powder manufactured by laser deposition, comprising the following steps:

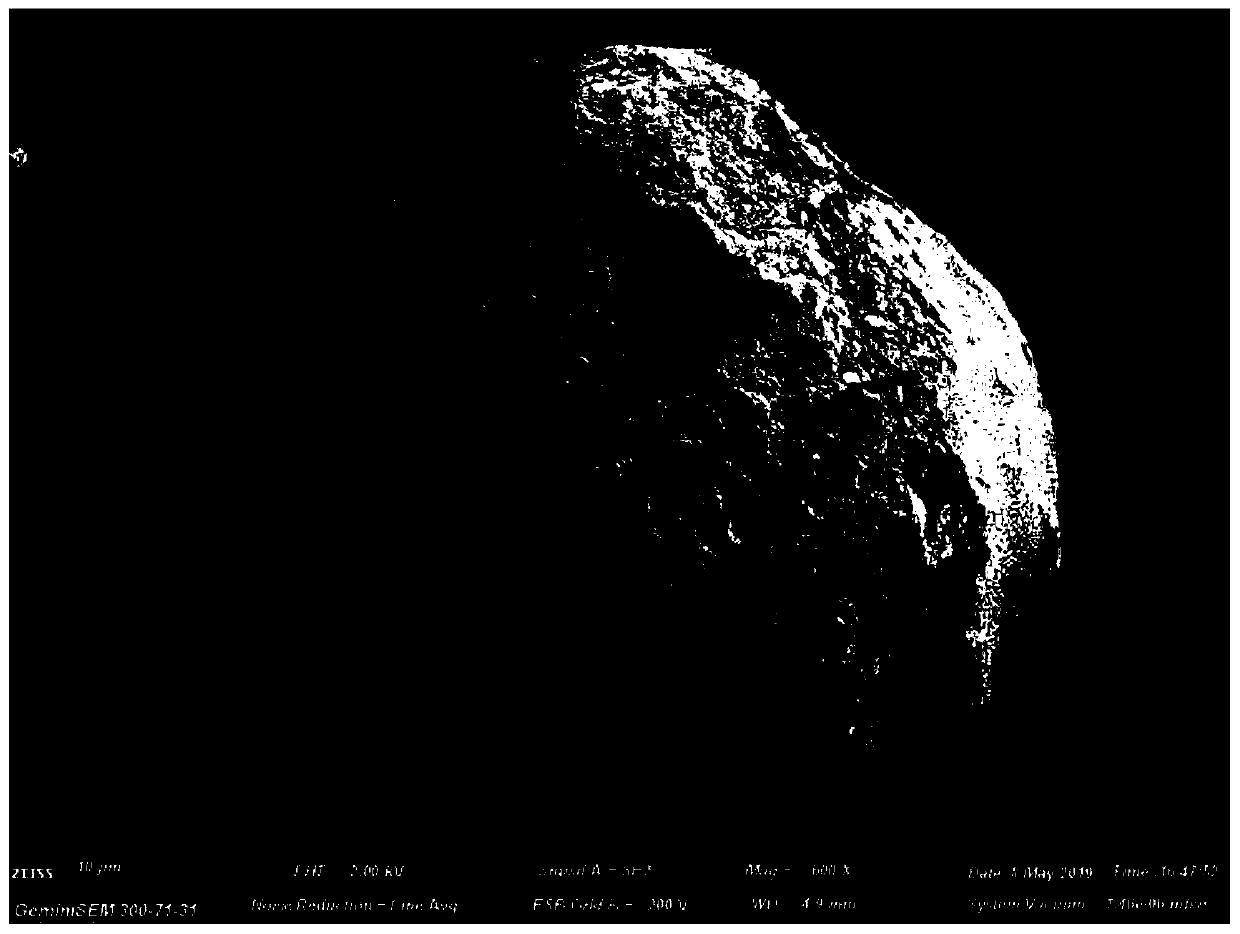

[0040] Step 1: Preparation of graphene sheets by combined thermal expansion-ultrasonic method

[0041] Take the raw material of intercalated expandable graphite and put it into a crucible, put the crucible into a muffle furnace with crucible tongs and heat it at 600°C for 3min, take it out and cool it down to obtain an expanded graphene sheet.

[0042] Take 0.15 g of the expanded graphene sheet and put it into a beaker, add 150 mL of absolute ethanol, and put it into an ultrasonic machine for ultrasonication for 2 hours to obtain few-layer graphene nanosheets.

[0043] Step 2: Wet ball milling

[0044] Before ball milling, prepare 2-5mm ball milling balls and put them into a beaker, add absolute ethanol and ultrasonically clean them for 3-5 times, each time for 5-10 minutes, to obtain 2-5mm ball milling balls after removal of impuritie...

Embodiment 2

[0055] A preparation method for a graphene-aluminum-based composite powder manufactured by laser deposition, comprising the following steps:

[0056] Step 1: Preparation of graphene sheets by combined thermal expansion-ultrasonic method

[0057] Take the intercalated expandable graphite raw material and put it into a crucible, put the crucible into a muffle furnace with a crucible tongs and heat it at 500°C for 5 minutes, take it out and cool it down to obtain an expanded graphene sheet.

[0058] Take 0.3g of the expanded graphene sheet and put it into a beaker, add 200mL of absolute ethanol, put it into an ultrasonic machine and sonicate for 5h, and obtain few-layer graphene nanosheets.

[0059] Step 2: Wet ball milling

[0060] Before ball milling, prepare 2-5mm ball milling balls and put them into a beaker, add absolute ethanol and ultrasonically clean them for 3-5 times, each time for 5-10 minutes, to obtain 2-5mm ball milling balls after removal of impurities.

[0061] ...

Embodiment 3

[0071] A preparation method for a graphene-aluminum-based composite powder manufactured by laser deposition, comprising the following steps:

[0072] Step 1: Preparation of graphene sheets by combined thermal expansion-ultrasonic method

[0073] Take the intercalated expandable graphite raw material and put it into a crucible, put the crucible into a muffle furnace with a crucible tongs and heat it at 500°C for 5 minutes, take it out and cool it down to obtain an expanded graphene sheet.

[0074] Take 0.2 g of the expanded graphene sheet and put it into a beaker, add 200 mL of absolute ethanol, and put it into an ultrasonic machine for ultrasonication for 4 hours to obtain few-layer graphene nanosheets.

[0075] Step 2: Wet ball milling

[0076] Before ball milling, prepare 2-5mm ball milling balls and put them into a beaker, add absolute ethanol and ultrasonically clean them for 3-5 times, each time for 5-10 minutes, to obtain 2-5mm ball milling balls after removal of impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com