Method for leaching antimony oxide materials and electrodeposition-producing metalic antimony through tartaric acid system

A technology of tartaric acid and antimony oxide, which is applied in the improvement of process efficiency, photography process, instruments, etc., can solve problems such as corrosion, and achieve the effect of less reagent consumption, less corrosiveness, and clean extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

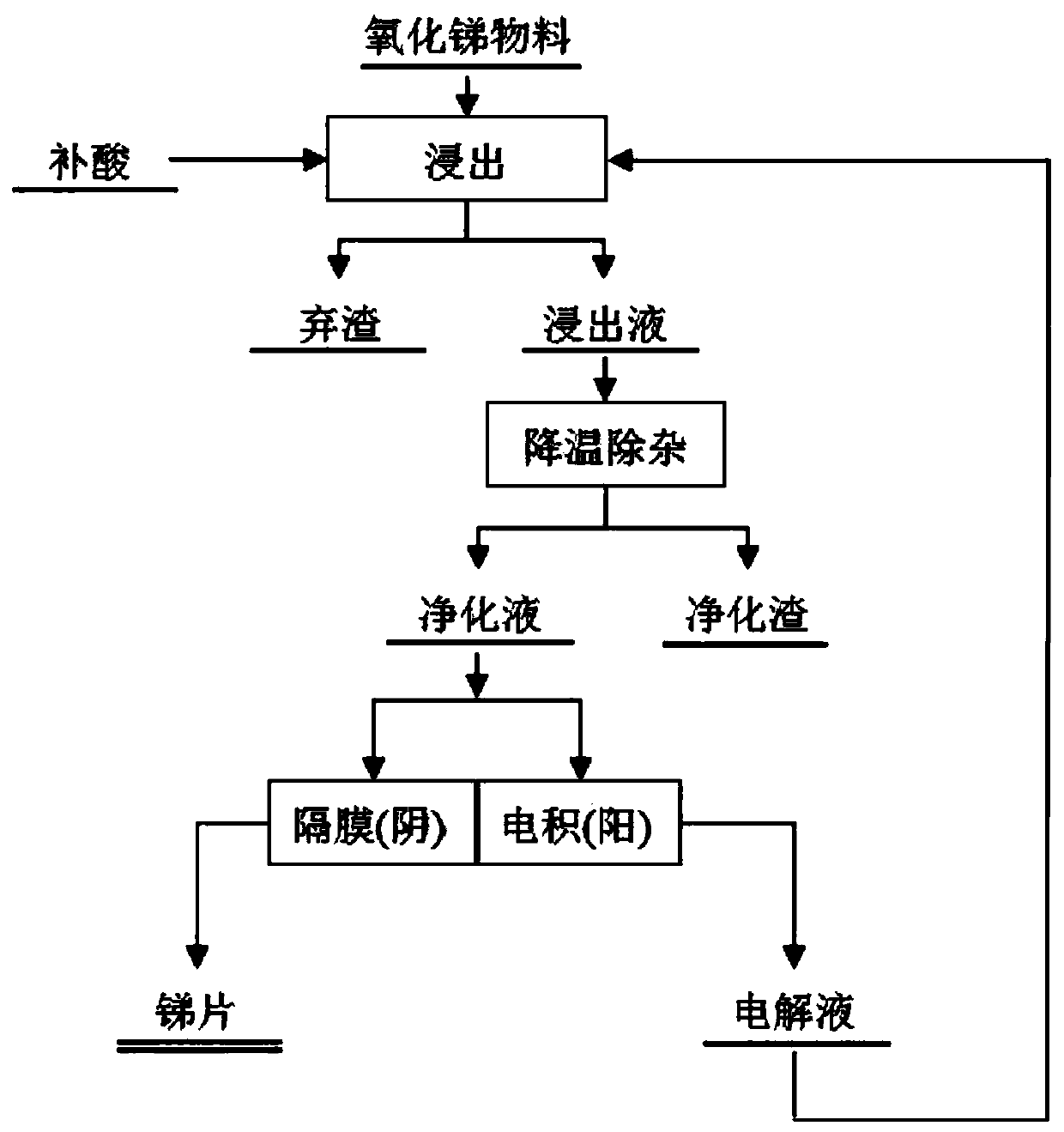

[0042] This embodiment provides a method for leaching antimony oxide materials with tartaric acid system and producing antimony metal by electrowinning. The process flow chart is as attached figure 1 shown. The antimony oxide material used as the test raw material is obtained by oxidation and roasting of antimony sulfide concentrate, and its composition (wt.%) is: Sb 79.36, S 0.34, Fe 0.13, As 0.07, Pb 0.06, SiO 2 0.58, CaO 1.02; Tartaric acid, potassium hydrogen tartrate, and sodium hydrogen tartrate used as leaching agents are all industrial pure grades, and are prepared to the required concentration by adding water.

[0043] Specifically include the following steps:

[0044] S1. Leaching: Weigh 100g of antimony oxide powder of the above ingredients, add 800mL of tartaric acid-sodium hydrogen tartrate leaching solution according to the liquid-solid ratio of 8:1, wherein the total concentration of tartrate groups is 150g / L, and the molar ratio of tartaric acid to sodium hydr...

Embodiment 2

[0049] This embodiment provides a method for leaching antimony oxide materials with tartaric acid system and producing antimony metal by electrowinning. The process flow chart is as attached figure 1 shown. The antimony oxide material used as the experimental raw material is the same as that in Example 1, and the leaching solution used is prepared from the electrowinning solution obtained in step S3 in Example 1.

[0050] Specifically include the following steps:

[0051] S1. Leaching: Weigh 100g of antimony oxide powder of the above ingredients, add 600mL of the electrowinning solution of Example 1 according to the liquid-solid ratio of 6:1, and add 10g of tartaric acid, at a temperature of 70°C and a stirring speed of 800rpm After reacting for 1 hour, the supernatant and the final slag were separated by filtration to obtain 8.3 g of slag. After analysis, the final slag contained 12.09% of antimony, and the leaching rate of antimony was calculated to be 98.74%.

[0052] S2....

Embodiment 3

[0055] This embodiment provides a method for leaching antimony oxide materials with tartaric acid system and producing antimony metal by electrowinning. The process flow chart is as attached figure 1 shown. The antimony oxide material used as the experimental raw material is the same as that in Example 1, and the leaching solution used is prepared from the electrowinning solution obtained in Step S3 in Example 2.

[0056] Specifically include the following steps:

[0057] S1. Leaching: Weigh 100g of antimony oxide powder of the above ingredients, add 400mL of the electrolytic solution in Example 2 according to the liquid-solid ratio of 4:1, and add 2g of tartaric acid, at a temperature of 40°C and a stirring speed of 400rpm After reacting for 3 hours, the supernatant and the final slag were separated by filtration to obtain 11.6 g of slag. After analysis, the final slag contained 36.66% of antimony, and the leaching rate of antimony was calculated to be 94.64%.

[0058] S2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com