Continuous synthesis method and device of solvent-free waterborne polyurethane

A technology of water-based polyurethane and synthesis method, which is applied in the field of continuous synthesis method and device of solvent-free water-based polyurethane, which can solve the problems of poor product stability, low solid content of polyurethane dispersion, poor compatibility, etc., and achieve high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 5kg of polyethylene oxide diol with a relative molecular mass of 2000, 5kg of polypropylene oxide diol with a relative molecular mass of 2000, 10.8kg of isophorone diisocyanate, 2.3kg of 1,4-butanediol and 120g of stannous octoate , and reacted at 80°C for 5h to obtain a clear solvent-free polyurethane prepolymer.

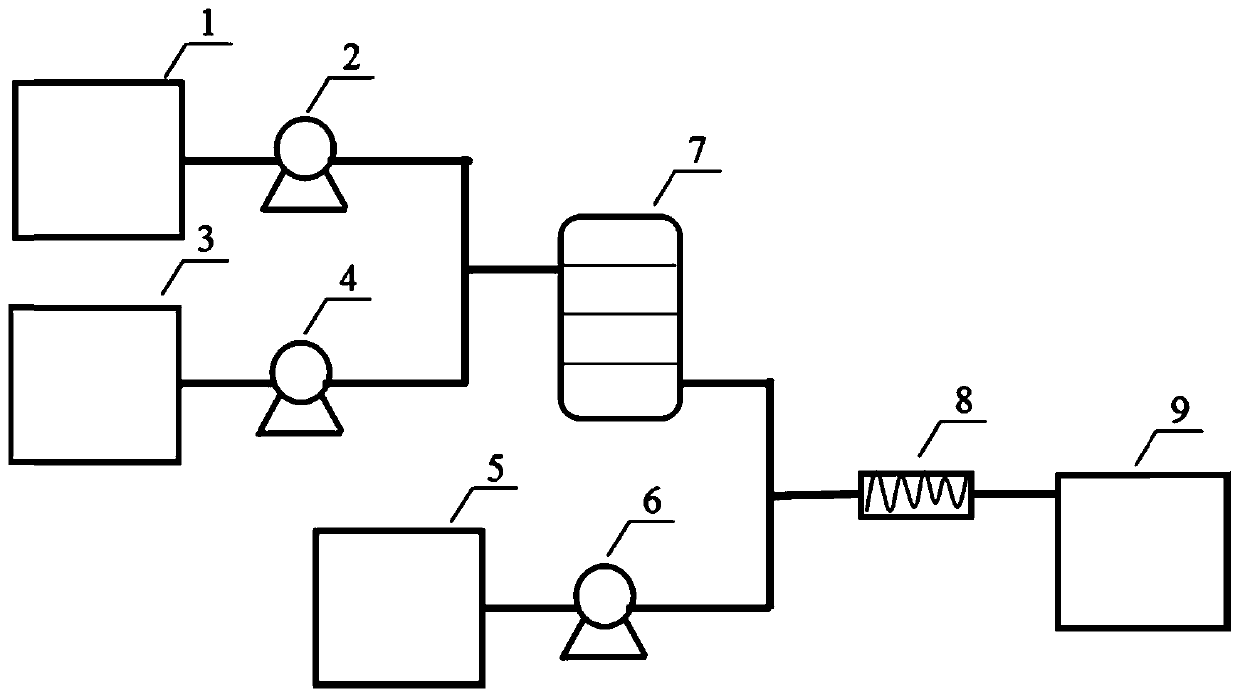

[0032] The above-mentioned polyurethane prepolymer is delivered to the emulsifier by the first metering pump from the prepolymer tank at a flow rate of 10kg / h, and at the same time, deionized water is delivered to the emulsifier by the second metering pump at a flow rate of 10L / h. The emulsifier performs strong dispersion and emulsification at a speed of 4000rpm, and the obtained polyurethane dispersion is sent to a static mixer with an aspect ratio of 60. At the same time, 40% of N-(2-aminoethyl)- The aqueous solution of sodium 2-aminoethanesulfonate is delivered to the static mixer by the third metering pump at a flow rate of 1.5 L / h, and through the effic...

Embodiment 2

[0034] With the polyneopentyl glycol adipate of 3kg relative molecular mass 1000, the polytetrahydrofuran diol of 3kg relative molecular mass 1000, 8.9kg toluene diisocyanate, 1kg ethylene glycol, 1.5kg neopentyl glycol and 40g stannous octoate, React at 85°C for 5h to obtain a clear solvent-free polyurethane prepolymer.

[0035] The above-mentioned polyurethane prepolymer is delivered to the emulsifier by the first metering pump from the prepolymer tank with a flow rate of 5kg / h. At the same time, deionized water is delivered to the emulsifier by the second metering pump at a flow rate of 8L / h. The emulsifier performs strong dispersion and emulsification at a speed of 5000rpm, and the obtained polyurethane dispersion is sent to a static mixer with an aspect ratio of 40. At the same time, the mass fraction of 50% N-(2-aminoethyl)- The aqueous solution of sodium 3-aminoethanesulfonate was delivered to the static mixer by the third metering pump at a flow rate of 1.2 L / h, and th...

Embodiment 3

[0037] 6kg of polybutylene adipate with a relative molecular mass of 3000, 2kg of polybutylene adipate with a relative molecular mass of 1000, 10.52kg of hydrogenated phenylmethane diisocyanate, 2kg of 1,4-butanediol, 0.5kg Diethylene glycol and 50g of dibutyltin dilaurate were reacted at 90°C for 4 hours to obtain a clear solvent-free polyurethane prepolymer.

[0038] The above-mentioned polyurethane prepolymer is delivered to the emulsifier by the first metering pump from the prepolymer tank with a flow rate of 15kg / h. At the same time, deionized water is delivered to the emulsifier by the second metering pump at a flow rate of 10L / h. The emulsifier performs strong dispersion and emulsification at a speed of 6000rpm, and the obtained polyurethane dispersion is sent to a static mixer with an aspect ratio of 80. At the same time, 30% of N-(3-aminoethyl)- The aqueous solution of sodium 2-aminoethanesulfonate was transported into the static mixer by the third metering pump at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com