Stainless steel for valve spring and preparation method of steel wire thereof

A valve spring and stainless steel wire technology, which is applied in the fields of stainless steel and its preparation, spring steel and its preparation, and austenitic stainless steel wire, can solve the problem of high alloy cost and achieve the effects of low alloy cost, excellent fatigue performance and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the chemical composition of a valve spring stainless steel is shown in Table 1.

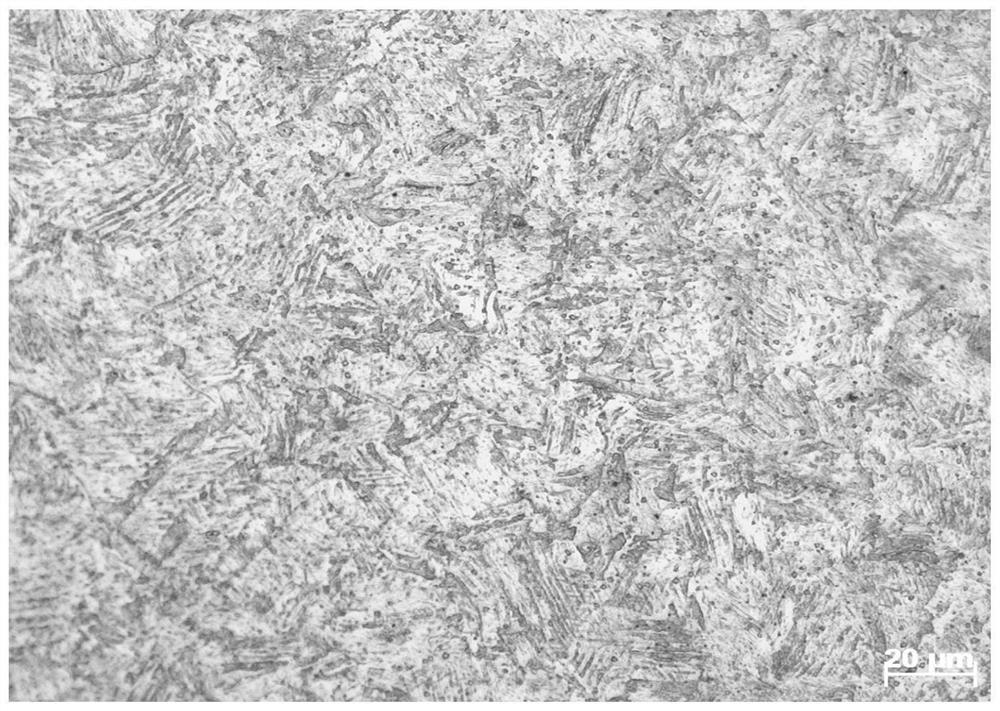

[0040] In this example, see figure 1 And table 2, a kind of preparation method of valve spring stainless steel wire, comprises the steps:

[0041] a. melting and casting process: the valve spring of the present embodiment is smelted into molten steel with stainless steel, and then the molten steel is continuously casted into a round billet;

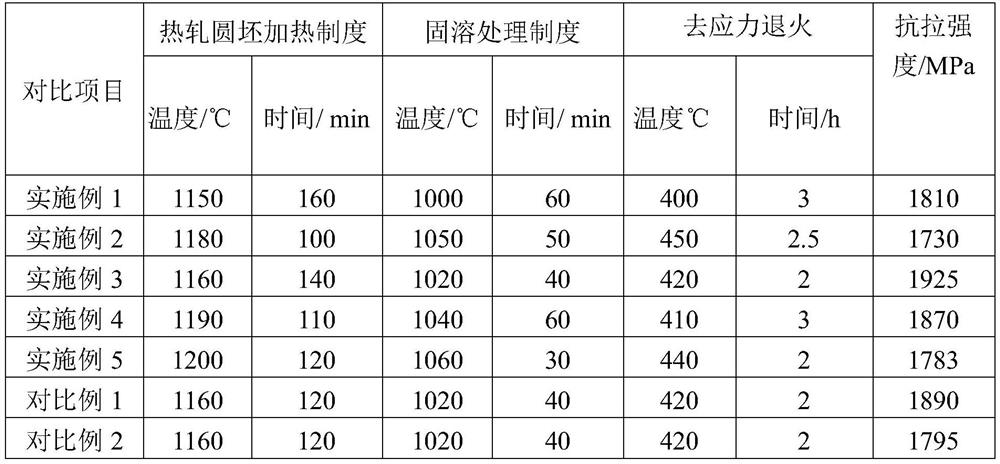

[0042] b. Hot rolling process: Peel the round billet prepared in the step a, then heat the round billet to 1150°C, and obtain a hot-rolled wire rod after hot rolling, and the heating time is 160min;

[0043] c. Solution heat treatment: performing solution heat treatment on the hot-rolled wire rod prepared in the step b, controlling the solution heat treatment temperature to be 1000° C., and the heating time to be at least 60 minutes;

[0044] d. Intermediate treatment process: pickling, phosphating, and saponifying the wire rod a...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, and the special features are:

[0049] In this embodiment, the chemical composition of a valve spring stainless steel is shown in Table 1.

[0050] In this embodiment, referring to Table 2, a method for preparing a stainless steel wire for a valve spring comprises the following steps:

[0051] a. melting and casting process: the valve spring of the present embodiment is smelted into molten steel with stainless steel, and then the molten steel is continuously casted into a round billet;

[0052] b. Hot rolling process: Peel the round billet prepared in the step a, then heat the round billet to 1180°C, and obtain a hot-rolled wire rod after hot rolling, and the heating time is 100 minutes;

[0053] c. Solution heat treatment: performing solution heat treatment on the hot-rolled wire rod prepared in the step b, controlling the solution heat treatment temperature to be 1050° C., and the heating time to be at least 50 m...

Embodiment 3

[0058] This embodiment is basically the same as the previous embodiment, and the special features are:

[0059] In this embodiment, the chemical composition of a valve spring stainless steel is shown in Table 1.

[0060] In this embodiment, referring to Table 2, a method for preparing a stainless steel wire for a valve spring comprises the following steps:

[0061] a. melting and casting process: the valve spring of the present embodiment is smelted into molten steel with stainless steel, and then the molten steel is continuously casted into a round billet;

[0062] b. Hot rolling process: Peel the round billet prepared in the step a, then heat the round billet to 1160°C, and obtain a hot-rolled wire rod after hot rolling, and the heating time is 140min;

[0063] c. Solution heat treatment: performing solution heat treatment on the hot-rolled wire rod prepared in the step b, controlling the solution heat treatment temperature to be 1020° C., and the heating time to be at leas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com