Method for preparing silicon-carbon composite negative material by low-temperature plasmas

A low-temperature plasma and low-temperature plasma technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low specific capacity, small amplitude, complicated preparation process, etc., and achieve improved cycle performance and structural stability. Strong and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

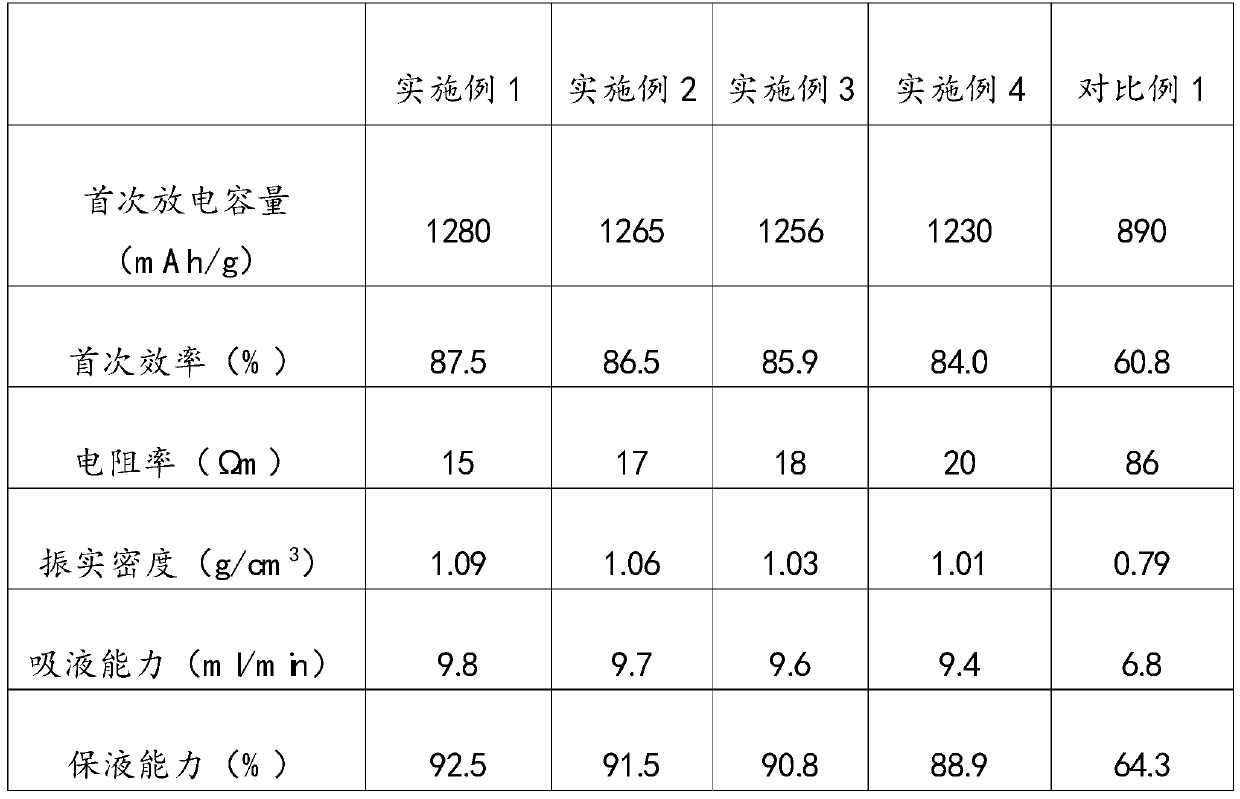

Examples

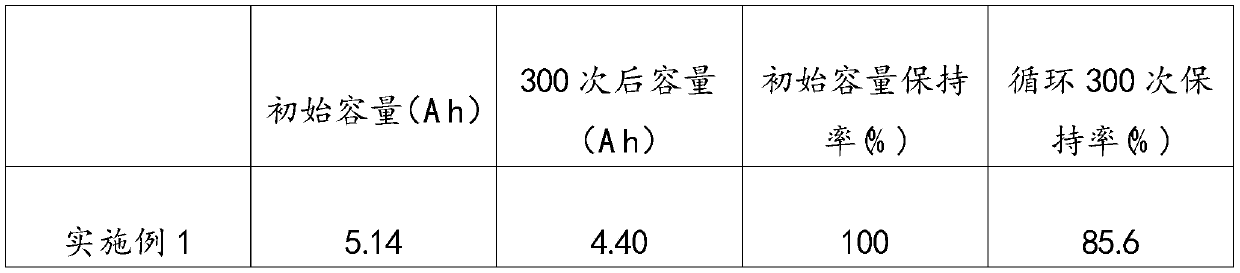

Embodiment 1

[0024] A method for preparing a silicon-carbon composite negative electrode material by low-temperature plasma, comprising the following steps:

[0025] (1) Preparation of nano-silicon complex

[0026] Add nano-silicon, silane coupling agent, additives and catalysts into the organic solvent, mix and stir evenly, and process through low-temperature plasma technology. After the treatment is completed, ultrasonically disperse and filter to obtain nano-silicon complexes;

[0027] (2) Preparation of silicon-carbon composite anode materials containing nano-silicon / silicon monoxide by chemical vapor deposition

[0028] Put the nano-silicon complex into the vapor deposition tube furnace, raise the temperature of the tube furnace to 500°C under the protection of inert gas, and keep it warm for 6 hours. After the heat preservation is over, cool down, then stop the inert gas and replace it with reducing gas hydrogen to obtain the silicon-carbon composite negative electrode material.

Embodiment 2

[0030] A method for preparing a silicon-carbon composite negative electrode material by low-temperature plasma, comprising the following steps:

[0031] (1) Preparation of nano-silicon complex

[0032] Add 10g of nano-silicon, 1g of vinyltriethoxysilane, 0.5g of mesoporous molecular sieve SBA-15 and 0.1g of tertiary amine into 100g of benzene, mix and stir evenly, pass the processing frequency at 15kHz, the air gap distance is 10mm, and the power is 100W low-temperature plasma technology was used to treat at room temperature for 10 minutes. After the treatment was completed, the nano-silicon complex was obtained by ultrasonic dispersion and filtration;

[0033] (2) Preparation of silicon-carbon composite anode materials containing nano-silicon / silicon monoxide by chemical vapor deposition

[0034] Put the nano-silicon complex into the vapor deposition tube furnace, raise the temperature of the tube furnace to 600°C under the protection of inert gas argon, and keep it warm for...

Embodiment 3

[0036] A method for preparing a silicon-carbon composite negative electrode material by low-temperature plasma, comprising the following steps:

[0037] (1) Preparation of nano-silicon complex

[0038] Add 15g of nano-silicon, 3g of γ-glycidyl ether propyl trimethoxysilane, 1g of mesoporous molecular sieve SBA-15 and 0.2g of N, N-diethylformamide into 100g of cyclohexane, mix and stir evenly, and pass through the processing frequency of 18kHz, the air gap distance is 15mm, and the power is 150W. The low-temperature plasma technology is processed at room temperature for 30 minutes. After the treatment is completed, the nano-silicon composite is obtained by ultrasonic dispersion and filtration;

[0039] (2) Preparation of silicon-carbon composite anode materials containing nano-silicon / silicon monoxide by chemical vapor deposition

[0040] Put the nano-silicon complex into the vapor deposition tube furnace, raise the temperature of the tube furnace to 700°C under the protection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com