Friction test device for steel wire rope

A test device and wire rope technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of large deviation of test data, large deviation between test data and actual data, high production and use costs, and achieve strong test load capacity , reduce the cost of use, reduce the effect of occupying an area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

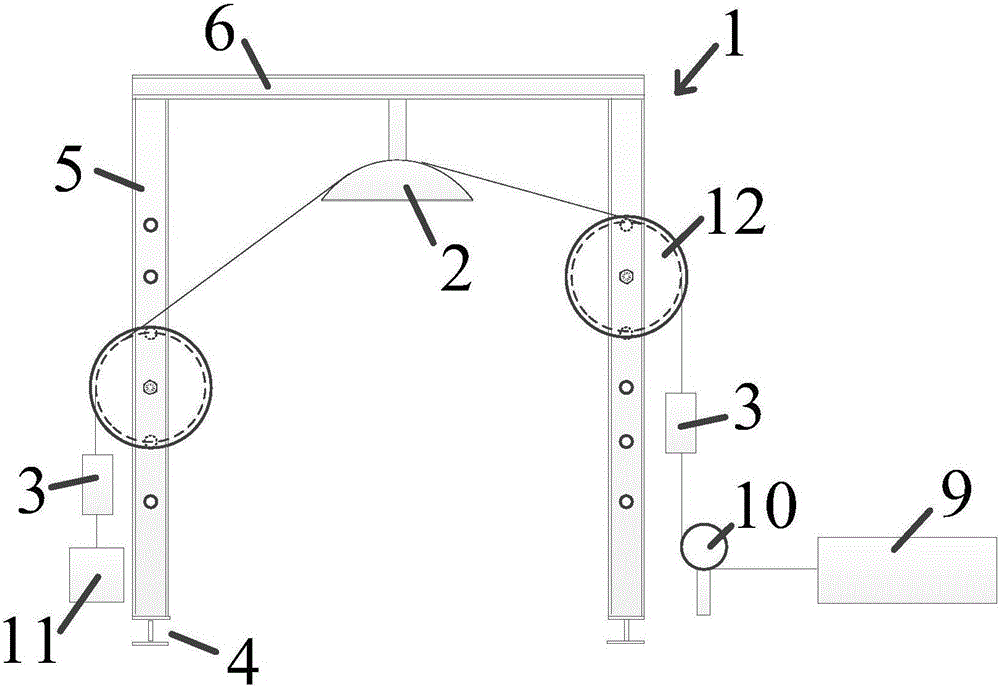

[0041] Such as figure 1 Shown, a kind of friction test device of steel wire rope, described steel wire rope comprises central steel wire and the outer layer steel wire strand that is arranged around described central steel wire; components,

[0042] The fixed frame 1 is provided with a saddle 2 connected with the steel wire rope,

[0043] The test assembly is provided with a tension gauge 3 .

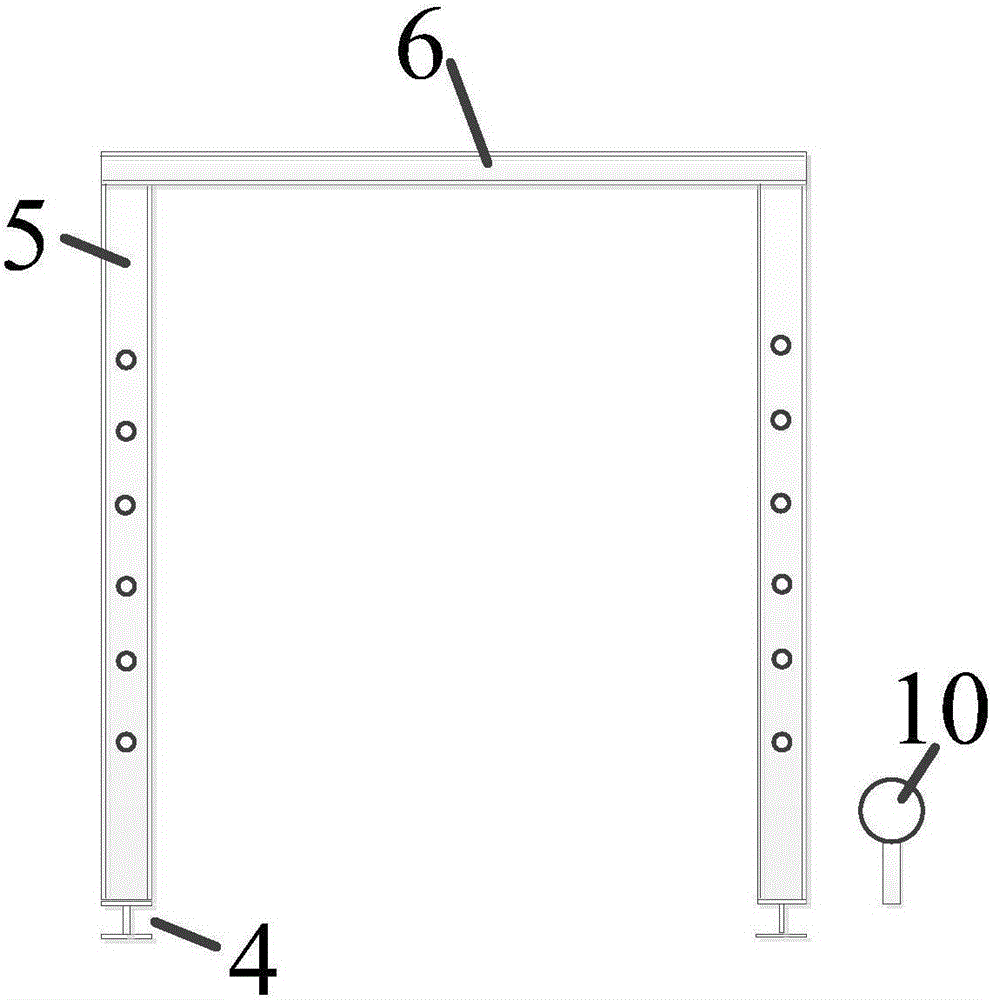

[0044] Such as figure 2 As shown, the fixed frame 1 is a doorframe-shaped frame, which includes a vertically arranged support rod 5, a base that is respectively arranged at the bottom end and the top end of the described support rod 5, and a crossbeam 6 arranged longitudinally;

[0045] The base is composed of two horizontally arranged I-beams 4,

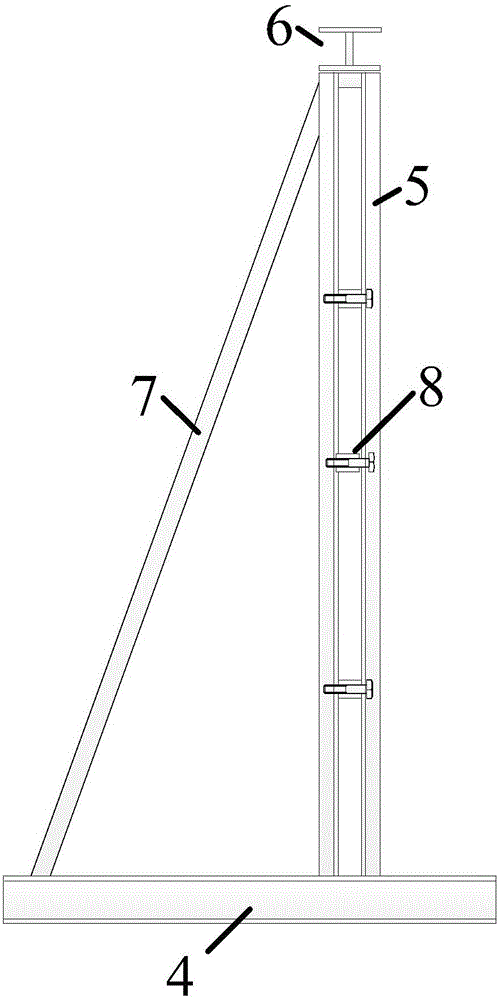

[0046] A diagonal brace 7 is arranged between the support rod 5 and the I-beam 4 , one end of the diagonal brace 7 is connected to the upper end of the support rod 5 , and the other end is connected to the I-beam 4 to form a right triang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com