High-strength anti-crack environment-friendly concrete and preparation process thereof

A technology of environmentally friendly concrete and ceramsite concrete, which is applied in the field of concrete, can solve problems such as limiting the application of recycled concrete, affecting the durability of concrete, and low aggregate strength, and achieves stable and efficient intermolecular bonding, strong overall structural stability, and reduced water absorption. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

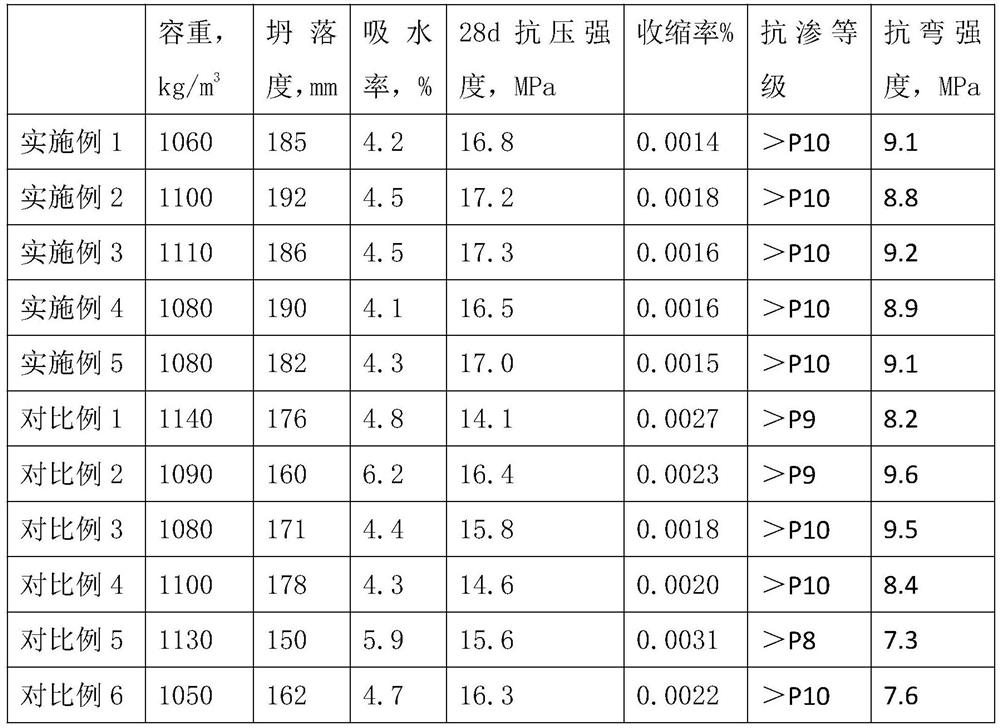

Examples

Embodiment 1

[0024] A high-strength anti-cracking environment-friendly concrete, including the following components by mass: 430 parts of PC42.5 cement, 80 parts of fly ash, 520 parts of recycled lightweight aggregate, 120 parts of coated sponge iron, and fluorocarbon modified polyacrylamide 20 parts of copolymer, 45 parts of sodium bicarbonate, 60 parts of polyphenylene particles, 1.5 parts of polycarboxylate superplasticizer, 200 parts of mixing water, among which, recycled lightweight aggregates include waste ceramsite concrete blocks, waste rock wool boards, Coated sponge iron includes sponge iron, borax, polyvinyl alcohol solution, and rice husk.

[0025] Among them, the mass percentages of waste ceramsite concrete block and rock wool board in the recycled lightweight aggregate are 70% and 30% respectively; the mass parts of each material in the coated sponge iron are 20 parts of sponge iron and 1 part of borax , 10 parts of polyvinyl alcohol solution, 3 parts of rice husk.

[0026] ...

Embodiment 2

[0035] A high-strength crack-resistant environmentally friendly concrete, including the following components by mass: 350 parts of PC42.5 cement, 120 parts of fly ash, 500 parts of recycled lightweight aggregate, 180 parts of coated sponge iron, and fluorocarbon modified polyacrylamide 20 parts of copolymer, 60 parts of sodium bicarbonate, 60 parts of polyphenylene particles, 1.4 parts of polycarboxylate superplasticizer, 220 parts of mixing water, among which, recycled lightweight aggregates include waste ceramsite concrete blocks, waste rock wool boards, Coated sponge iron includes sponge iron, borax, polyvinyl alcohol solution, and rice husk.

[0036] Among them, the mass percentages of waste ceramsite concrete block and rock wool board in the recycled lightweight aggregate are 65% and 35% respectively; the mass parts of each material in the coated sponge iron are 20 parts of sponge iron and 1.5 parts of borax , 15 parts of polyvinyl alcohol solution, 4 parts of rice husk. ...

Embodiment 3

[0043] A high-strength crack-resistant environmentally friendly concrete, including the following components by mass: 480 parts of PC42.5 cement, 60 parts of fly ash, 600 parts of recycled lightweight aggregate, 150 parts of coated sponge iron, and fluorocarbon modified polyacrylamide 10 parts of copolymer, 50 parts of sodium bicarbonate, 80 parts of polyphenylene particles, 2 parts of polycarboxylate superplasticizer, 160-250 parts of mixing water, among which, recycled lightweight aggregates include waste ceramsite concrete blocks, waste rock wool Board, coated sponge iron includes sponge iron, borax, polyvinyl alcohol solution, rice husk.

[0044] Among them, the mass percentages of waste ceramsite concrete blocks and rock wool boards in the recycled lightweight aggregate are 80% and 20% respectively; the mass parts of each material in the coated sponge iron are 10 parts of sponge iron and 0.5 parts of borax , 10 parts of polyvinyl alcohol solution, 5 parts of rice husk.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com