Preparation method of high-Hk samarium-cobalt sintered permanent magnet material

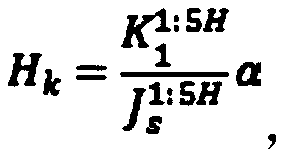

A permanent magnet material, samarium cobalt technology, applied in the direction of magnetic materials, inductors/transformers/magnet manufacturing, magnetic objects, etc., can solve the problems that the preparation of samarium cobalt sintered permanent magnets cannot be realized, and can not be satisfied, so as to increase the knee point coercivity Force, increased formation rate, reduced size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] a high H k The preparation method of samarium cobalt sintered permanent magnet material comprises the following method steps:

[0028] Ingredients: The raw materials of permanent magnet materials are formulated according to the following formula. According to weight percentage, samarium cobalt permanent magnet materials are prepared from the following raw materials: Sm25.2wt.%, Fe15.0wt.%, Cu5.7wt.%, Zr2. 8wt.%, the balance is Co;

[0029] Melting alloy ingots: put the prepared raw materials in the batching step into a vacuum induction melting furnace to melt the ingots to obtain alloy blanks;

[0030] Powder making: Coarse crushing and medium crushing of the alloy body, and under the protection of 120# solvent gasoline as the medium, use stirring ball milling to grind to an area average particle size of SMD5.2μm to obtain samarium cobalt magnetic powder;

[0031] Drying: drying the samarium cobalt magnetic powder obtained by powder milling;

[0032] Orientation bill...

Embodiment 2

[0036] a high H k The preparation method of samarium cobalt sintered permanent magnet material comprises the following method steps:

[0037] Ingredients: The raw materials of permanent magnet materials are formulated according to the following formula. According to weight percentage, samarium cobalt permanent magnet materials are prepared from the following raw materials: Sm25.2wt.%, Fe15.5wt.%, Cu6.1wt.%, Zr3. 0wt.%, the balance is Co;

[0038] Melting alloy ingots: put the prepared raw materials in the batching step into a vacuum induction melting furnace to melt the ingots to obtain alloy blanks;

[0039] Powder making: Coarse crushing and medium crushing of the alloy body, and under the protection of 120# solvent gasoline as the medium, use stirring ball milling to grind to an area average particle size of SMD5.6μm to obtain samarium cobalt magnetic powder;

[0040] Drying: drying the samarium cobalt magnetic powder obtained by powder milling;

[0041]Orientation bille...

Embodiment 3

[0045] a high H k The preparation method of samarium cobalt sintered permanent magnet material comprises the following method steps:

[0046] Ingredients: The raw materials of permanent magnet materials are formulated according to the following formula. According to weight percentage, samarium cobalt permanent magnet materials are prepared from the following raw materials: Sm25.2wt.%, Fe15.8wt.%, Cu6.4wt.%, Zr3. 3wt.%, the balance is Co;

[0047] Melting alloy ingots: put the prepared raw materials in the batching step into a vacuum induction melting furnace to melt the ingots to obtain alloy blanks;

[0048] Powder making: Coarse crushing and medium crushing of the alloy body, under the protection of 120# solvent gasoline as the medium, use stirring ball milling to grind to an area average particle size of SMD4.5μm to obtain samarium cobalt magnetic powder;

[0049] Drying: drying the samarium cobalt magnetic powder obtained by powder milling;

[0050] Orientation billet: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com