Preparation method of high-performance Pb/Al coating

A high-performance, coating technology, applied in pressure inorganic powder coating and other directions, can solve the problems of low energy utilization rate of laser surface alloying technology, low production efficiency of ion beam implantation, low bonding strength of vapor deposition, etc., to improve friction The effect of service life, low cost and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

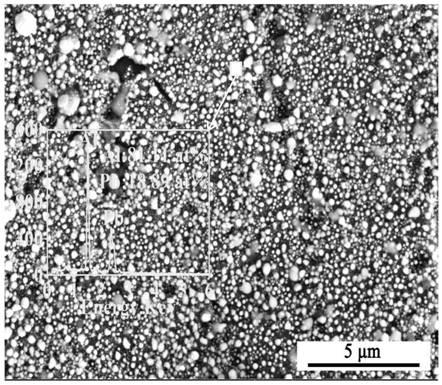

Image

Examples

Embodiment 1

[0028] (1) Alloy layer preparation:

[0029] In the first step, after cutting, pre-grinding, cleaning, and polishing the base 1060 block of pure aluminum, use mechanical coating technology to deposit pure Pb coating on the surface, with a thickness of 10 μm; select the ball material according to the technical requirements of mechanical coating equipment The mass ratio is 10:1, the rotational speed is 250r / min, the time is 1h, and the coating thickness is 10μm.

[0030] In the second step, the sample to be irradiated is fixed on the stage, and the "HOPE-1" type high-current pulsed electron beam device is used to vertically irradiate the surface of the preset coating, and then a Pb / Al alloy layer is obtained on the surface of the Al matrix sample. . Among them, the technical parameters of high-current pulsed electron beam irradiation are: electron beam energy is 23.4KeV, energy density is 3.5J / cm 2 , the target source distance is 15cm, the pulse width is 1.5μs, and the vacuum ...

Embodiment 2

[0035] (1) Alloy layer preparation:

[0036] In the first step, after cutting, pre-grinding, cleaning, and polishing the base 1060 block of pure aluminum, use mechanical coating technology to deposit pure Pb coating on the surface, with a thickness of 10 μm; select the ball material according to the technical requirements of mechanical coating equipment The mass ratio is 10:1, the rotational speed is 250r / min, the time is 1h, and the coating thickness is 10μm.

[0037] In the second step, the sample to be irradiated is fixed on the stage, and the "HOPE-1" type high-current pulsed electron beam device is used to vertically irradiate the surface of the preset coating, and then a Pb / Al alloy layer is obtained on the surface of the Al matrix sample. . Among them, the technical parameters of high-current pulsed electron beam irradiation are: electron beam energy is 23.4KeV, energy density is 3.5J / cm 2 , the target source distance is 15cm, the pulse width is 1.5μs, and the vacuum ...

Embodiment 3

[0042] (1) Alloy layer preparation:

[0043] In the first step, after cutting, pre-grinding, cleaning, and polishing the base 1060 block of pure aluminum, use mechanical coating technology to deposit pure Pb coating on the surface, with a thickness of 10 μm; select the ball material according to the technical requirements of mechanical coating equipment The mass ratio is 10:1, the rotational speed is 250r / min, the time is 1h, and the coating thickness is 10μm.

[0044] In the second step, the sample to be irradiated is fixed on the stage, and the "HOPE-1" type high-current pulsed electron beam device is used to vertically irradiate the surface of the preset coating, and then a Pb / Al alloy layer is obtained on the surface of the Al matrix sample. . Among them, the technical parameters of high-current pulsed electron beam irradiation are: electron beam energy is 23.4KeV, energy density is 3.5J / cm 2 , the target source distance is 15cm, the pulse width is 1.5μs, and the vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com