Processing technology of sheath material for severe cable of three-generation nuclear power plant

A technology of processing technology and sheathing material, which is applied in the field of processing technology of sheathing materials for harsh cables of third-generation nuclear power plants, can solve problems such as affecting product quality, poor process control, and generation of pores, and achieves overcoming mechanical properties and flame retardant properties. , Improve the dispersibility, reduce the effect of frictional heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

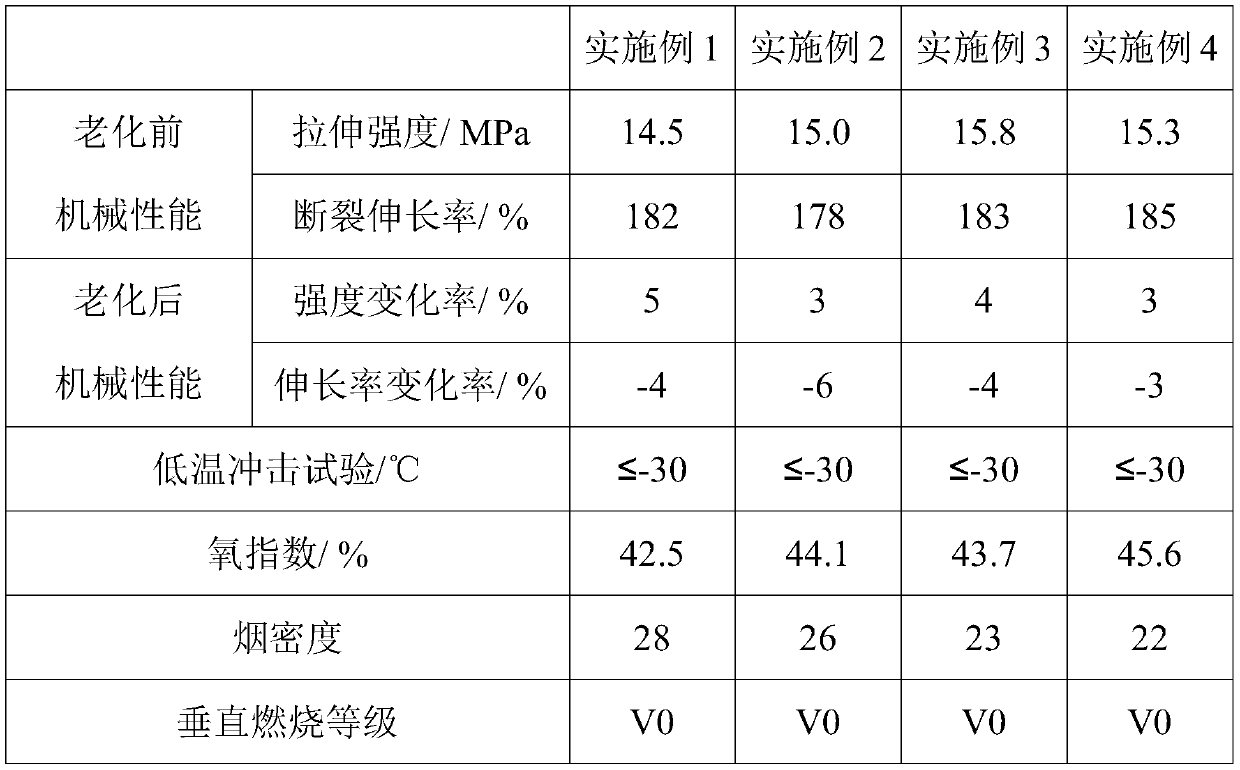

Examples

Embodiment 1

[0023] The processing technology of a kind of sheathing material for harsh cables of third-generation nuclear power plants proposed by the present invention comprises the following steps:

[0024] S1. Add 2 parts of α-zirconium phosphate into water, ultrasonically disperse for 20 minutes, then add 3 parts of zinc stannate hydrate, 0.8 parts of zinc oxide, 3.2 parts of sodium hydroxide and 7 parts of urea, ultrasonically, and stir the reaction at 70°C 5h, filter with suction, azeotropically distill the filter cake and n-butanol, dry, then mix with 4 parts of magnesium hydroxide, add to 90% ethanol solution, ultrasonically disperse, then add vinyltrimethoxysilane, at 40°C Stir and react for 3 hours, filter, and dry to obtain a composite flame retardant;

[0025] S2, get 30 parts of ethylene-vinyl acetate copolymer, 70 parts of low-density polyethylene, 1 part of antioxidant RD, 10242 parts of antioxidant, 1.5 parts of ultraviolet absorber UV-234, 2.5 parts of ultraviolet absorbe...

Embodiment 2

[0031] The processing technology of a kind of sheathing material for harsh cables of third-generation nuclear power plants proposed by the present invention comprises the following steps:

[0032]S1. Add 5 parts of α-zirconium phosphate into water, ultrasonically disperse for 30 minutes, then add 3.5 parts of zinc stannate hydrate, 1.3 parts of zinc oxide, 3.8 parts of sodium hydroxide and 8 parts of urea, ultrasonically, and stir at 80°C for reaction 6h, filter with suction, azeotropically distill the filter cake and n-butanol, dry, then mix with 7 parts of magnesium hydroxide, add to 90% ethanol solution, ultrasonically disperse, then add vinyltriethoxysilane, at 50 Stir and react at ℃ for 5 hours, filter and dry to obtain a composite flame retardant;

[0033] S2, get 40 parts of ethylene-vinyl acetate copolymer, 60 parts of low-density polyethylene, 2 parts of antioxidant RD, 10241 parts of antioxidant, 2.5 parts of ultraviolet absorber UV-234, 1.5 parts of ultraviolet abso...

Embodiment 3

[0039] A kind of processing technology of the sheathing material for severe cables of third-generation nuclear power plants proposed by the present invention is characterized in that it comprises the following steps:

[0040] S1. Add 3 parts of α-zirconium phosphate into water, ultrasonically disperse for 25 minutes, then add 3.2 parts of zinc stannate hydrate, 1 part of zinc oxide, 3.5 parts of sodium hydroxide and 7.4 parts of urea, ultrasonically, and stir at 75°C for reaction 5h, filter with suction, azeotropically distill the filter cake and n-butanol, dry, then mix with 5.4 parts of magnesium hydroxide, add to 90% ethanol solution, ultrasonically disperse, then add vinyltrimethoxysilane, at 40°C Stir and react for 3.5 hours, filter, and dry to obtain a composite flame retardant;

[0041] S2, get 35 parts of ethylene-vinyl acetate copolymer, 65 parts of low-density polyethylene, 1.5 parts of antioxidant RD, 1.5 parts of antioxidant 1024, 2 parts of ultraviolet absorber UV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com