Integrated preparation process for long-life hydrogen storage alloy film/nickel foil combined electrode material

A technology of hydrogen storage alloy and composite electrode, which is applied in metal material coating process, battery electrode, nickel storage battery, etc., can solve the problems of slow electrochemical reaction kinetics, large contact resistance, and performance hindrance of Ni-MH battery, etc. To achieve the effect of reducing the contact internal resistance, increasing the specific surface area, and accelerating the transmission rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

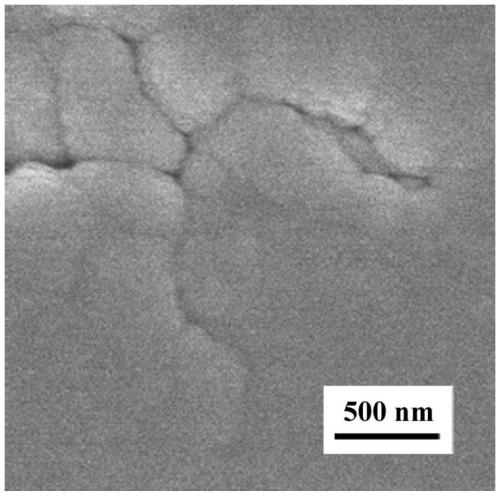

Image

Examples

Embodiment approach

[0032] An integrated preparation method for a long-life hydrogen storage alloy film / nickel foil composite electrode material, comprising the following steps:

[0033] a. Cut the nickel foil to 3.5cm×3.5cm as a substrate for sputtering, then immerse it in acetone and ultrasonicate for 10 minutes to remove oil stains on the surface of the substrate;

[0034] b. Rinse the substrate with deionized water for 3 times, then immerse it in deionized water and let it stand for 10 minutes;

[0035] c. Configure a 3mol / L hydrochloric acid solution, immerse the substrate in the prepared hydrochloric acid solution, and let it stand for 10 minutes to remove oxides on the surface of the substrate;

[0036] d. Take out the substrate, rinse it with deionized water 3 times, and then immerse it in deionized water again and let it stand for 10 minutes;

[0037] e. Finally, wash with absolute ethanol and dry in a vacuum environment for 6-12 hours.

Embodiment 1

[0039] The preparation process and steps in the present embodiment are as follows:

[0040] (1) Alloy preparation: according to La 0.6 Ce 0.3 Y 0.1 Ni 3.7 Co 0.75 Mn 0.3 Al 0.35 The chemical ratio of lanthanum, cerium, yttrium, nickel, cobalt, manganese and aluminum with a purity of ≥99.5 is vacuum induction smelted in a high-purity argon atmosphere, and the melting temperature is 1300 ° C to obtain an alloy ingot with a high cooling rate. , in order to improve the uniformity of the alloy. The ingot is then heat-treated in an argon protective atmosphere at a temperature of 1000°C, and then mechanically ground in an argon protective atmosphere to obtain hydrogen storage alloy powder with an average particle size of 50 μm;

[0041] (2) Target material preparation: Press the obtained hydrogen storage alloy powder into a target material with a diameter of ≤50mm and a thickness of ≤3mm, and use metal indium to bind it to the copper backplane to obtain a target for magnetron ...

Embodiment 2

[0045] The preparation process and steps in the present embodiment are as follows:

[0046] (1) Alloy preparation: according to La 0.6 Ce 0.3 Y 0.1 Ni 3.7 Co 0.75 Mn 0.3 Al 0.35 The chemical ratio of lanthanum, cerium, yttrium, nickel, cobalt, manganese and aluminum with a purity of ≥99.5 is vacuum induction smelted in a high-purity argon atmosphere, and the melting temperature is 1300 ° C to obtain an alloy ingot with a high cooling rate. , in order to improve the uniformity of the alloy. The ingot is then heat-treated in an argon protective atmosphere at a temperature of 1000°C, and then mechanically ground in an argon protective atmosphere to obtain hydrogen storage alloy powder with an average particle size of 50 μm;

[0047] (2) Target material preparation: Press the obtained hydrogen storage alloy powder into a target material with a diameter of ≤50mm and a thickness of ≤3mm, and use metal indium to bind it to the copper backplane to obtain a target for magnetron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com