A kind of preparation method of low turbidity bisphenol A type cyanate ester prepolymer

A type of cyanate ester and cyanate ester technology, applied in the field of polymer material synthesis, can solve the problems of reducing the quality of bisphenol A cyanate ester resin products, small contact area of raw materials, and low reaction yield, etc., so as to reduce product turbidity. degree and purification difficulty, reducing purification difficulty and high reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

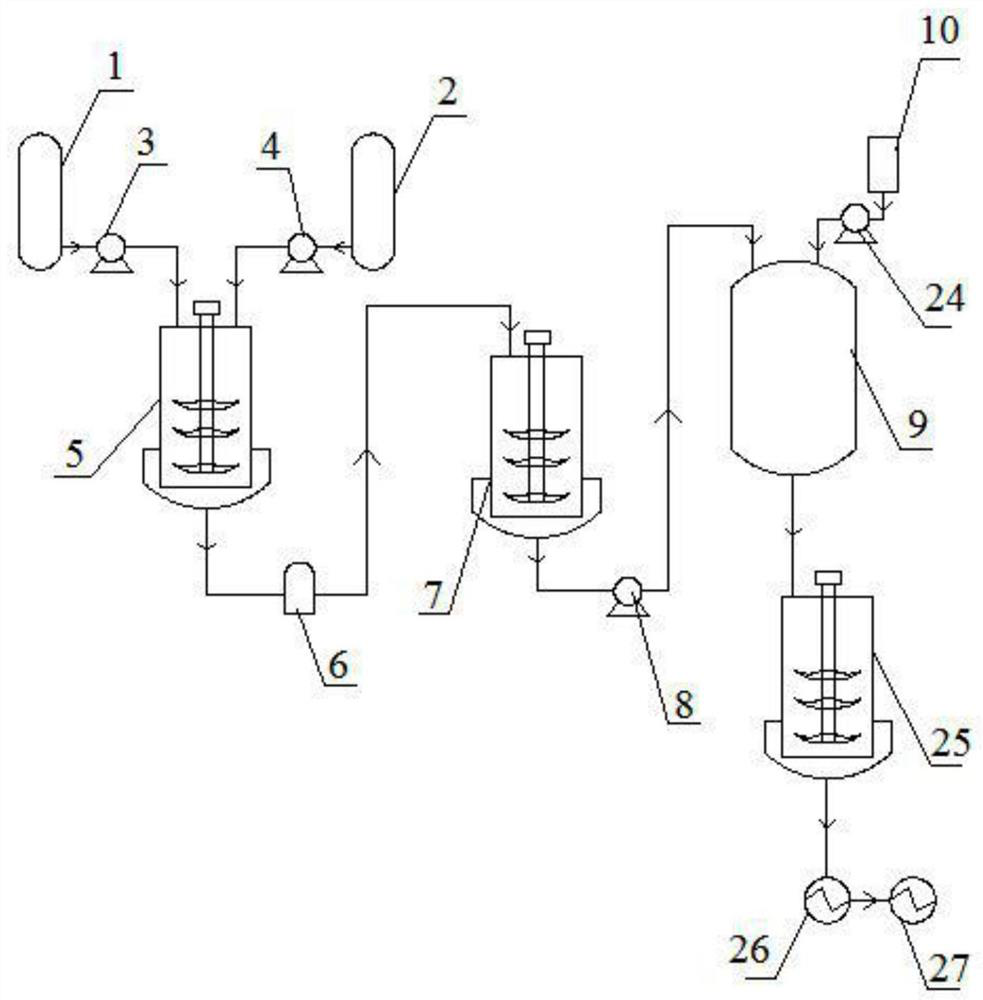

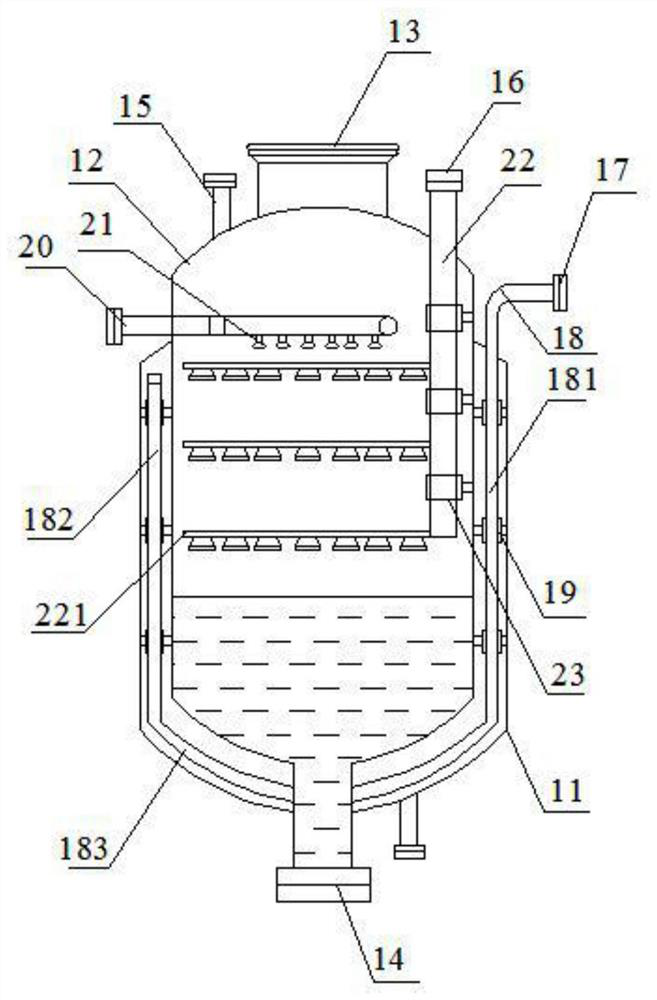

[0038] refer to Figure 1-3 Shown, the present embodiment provides a kind of preparation method of low turbidity bisphenol A type cyanate ester prepolymer, comprises the following steps:

[0039] S1. Weigh 228g of diphenol-based propane, 77.5g of cyanogen chloride, and 133.6g of triethylamine, dissolve the diphenol-based propane and triethylamine in tetrahydrofuran to form a mixed solution a, and put it into the first liquid storage tank 1; Cyanogen chloride is dissolved in dioxane to form a mixed solution b, which is pre-cooled to 0°C and loaded into the second liquid storage tank 2; the mixed solution a and the mixed solution b are respectively passed through the first booster pump 3 and the second Pump the booster pump 4 into the first reaction kettle 5, and react at -3°C for 5 minutes; the reaction liquid passes into the concentration tank 6, concentrates under reduced pressure to remove the solvent, adds petroleum ether, and recrystallizes at -2°C to obtain bisphenol A cy...

Embodiment 2

[0044] refer to Figure 1-3 Shown, the present embodiment provides a kind of preparation method of low turbidity bisphenol A type cyanate ester prepolymer, comprises the following steps:

[0045] S1. Weigh 228g of diphenol-based propane, 78.7g of cyanogen chloride, and 130.5g of triethylamine, dissolve the diphenol-based propane and triethylamine in acetonitrile to form a mixed solution a, and put it into the first liquid storage tank 1; Cyanogen chloride is dissolved in dimethylformamide to form a mixed solution b, which is pre-cooled to 2°C and loaded into the second liquid storage tank 2; the mixed solution a and the mixed solution b are respectively passed through the first booster pump 3 and the second The second booster pump 4 is pumped into the first reaction kettle 5, and reacted at -1°C for 6 minutes; the reaction liquid is passed into the concentration tank 6, concentrated under reduced pressure to remove the solvent, added cyclohexane, and recrystallized at 0°C to o...

Embodiment 3

[0050] refer to Figure 1-3 Shown, the present embodiment provides a kind of preparation method of low turbidity bisphenol A type cyanate ester prepolymer, comprises the following steps:

[0051] S1. Weigh 228g of diphenol-based propane, 80g of cyanogen chloride, and 143.7g of triethylamine, dissolve diphenol-based propane and triethylamine in tetrahydrofuran to form a mixed solution a, and put it into the first liquid storage tank 1; Chlorine Cyanide is dissolved in tetrahydrofuran to form a mixed solution b, which is pre-cooled to 5°C and loaded into the second liquid storage tank 2; the mixed solution a and the mixed solution b are respectively passed through the first booster pump 3 and the second booster pump 4 Pump into the first reaction kettle 5, and react at -4°C for 6 minutes; the reaction liquid is passed into the concentration tank 6, concentrated under reduced pressure to remove the solvent, add cyclopentane, and recrystallize at 3°C to obtain bisphenol A cyanat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com