Preparation method of super-hydrophobic bionic numerical control machining tool

A processing tool and super-hydrophobic technology, which is applied in the field of super-hydrophobic bionic CNC machining tool preparation, can solve the problems of time-consuming and labor-intensive tool replacement, reduced tool life, and reduced surface quality of workpieces, etc., to achieve high life and small friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

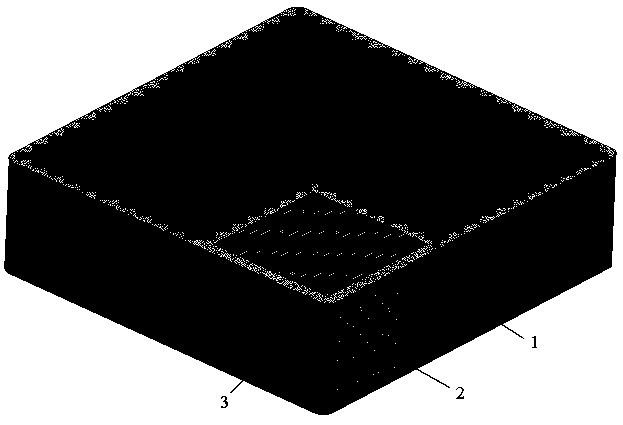

Embodiment 1

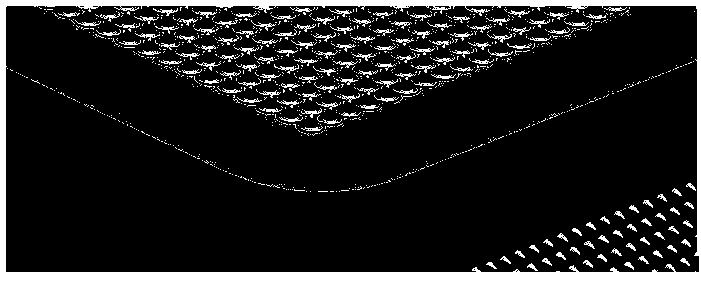

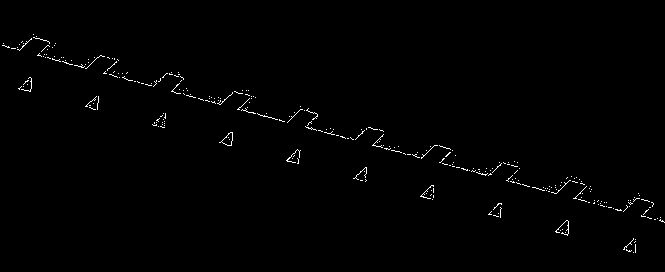

[0016] Embodiment 1: The cutting tool material is SG4 ceramic turning tool (composition is 45% aluminum oxide+55% TiC by weight percentage). First, a two-stage superhydrophobic micromorphology composed of micro-protrusions and micro-grooves is processed at a distance of 150 µm from the main and secondary cutting edges on the rake face and flank face of the tool by nanosecond laser; the processing parameters are: pump voltage 19V, scanning speed 5mm / s, repetition frequency 6Hz, scan 1 time; the corresponding micro-textured protrusion spacing is 40-60µm, and the height is about 40-50µm. Then, the femtosecond laser is used to process the serrated nanotexture at the radius of the tool tip; the processing parameters are: single pulse energy 1.75µJ, scanning speed 500µm / s, scanning once; the corresponding nanotexture spacing is about 300-400nm , the depth is about 100-150nm. Finally, supersonic flame spraying technology is used to prepare the mass percentage of 99% alumina + 1% gra...

Embodiment 2

[0017] Embodiment two: cutter material is hard alloy class cutting tool, as YT15 hard alloy car, milling cutter (composition is weight percent 79%WC+15%TiC+6%Co), YG6 hard alloy car, milling cutter (composition For weight percentage 94%WC +6%Co ) and so on. First, micron-scale pits and arches were prepared on the surface of H13 die steel (4Cr5MoSiV) with a picosecond laser to obtain a 10mm×10mm reverse lotus leaf shape, and this structure was used as a two-stage superhydrophobic micro-morphological processing template; the processing parameters are: Energy density 2.1J / cm 2 , repetition frequency 100kHz, single exposure time 0.5ms, 0.6ms, 0.7ms, repetition times 6-10. Then, using the electrolytic machining method, the reverse lotus leaf structure on the die steel was completely copied on the rake face and flank face of the cemented carbide tool to obtain two 10 mm × 10 mm distances from the main and auxiliary cutting edges of 150-200 µm. Segmented super-hydrophobic microscop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com