High-dispersity nano molybdenum disulfide water-based rolling liquid and preparation method thereof

A nano-molybdenum disulfide, high-dispersibility technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of surrounding environmental pollution and environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

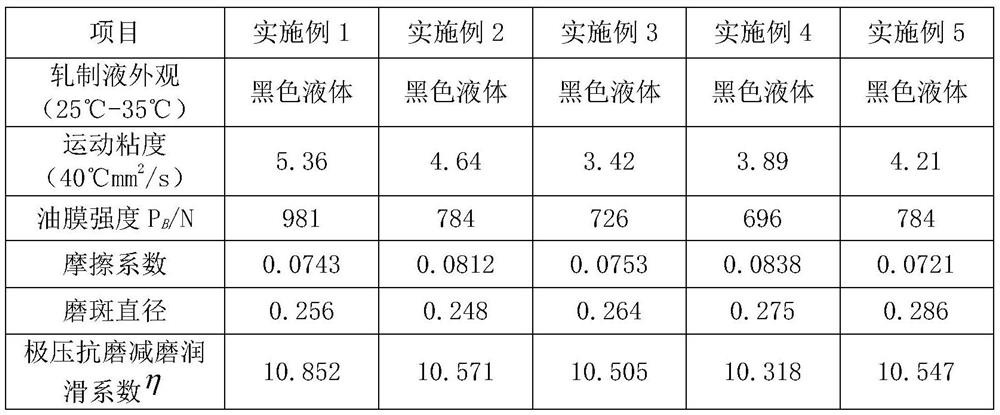

Examples

preparation example Construction

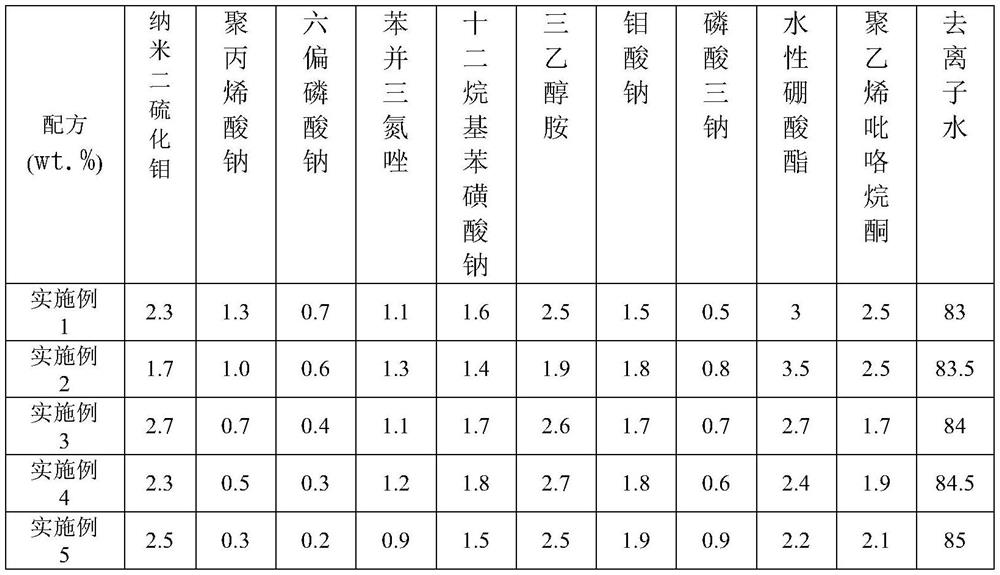

[0022] A preparation method of highly dispersed nano molybdenum disulfide water-based rolling liquid, comprising the steps of:

[0023] 1) Add deionized water into the reaction kettle, add nano-molybdenum disulfide, sodium polyacrylate and sodium hexametaphosphate during the stirring process; heat the solution to 60-80°C to realize surface modification of nano-molybdenum disulfide particles and scattered;

[0024] 2) Heat the solution containing the modified molybdenum disulfide nanoparticles to 75-80°C for heat preservation, and keep stirring for 30-40 minutes; then add benzotriazole, sodium dodecylbenzenesulfonate, triethanolamine , sodium molybdate, and trisodium phosphate, heated to 80-85°C, and stirred for 35-45 minutes; then added aqueous borate and polyvinylpyrrolidone, stopped heating, and continued to stir to room temperature;

[0025]3) Ultrasonic dispersion of the solution obtained in step 2) for 30 to 45 minutes, and the finally obtained black solution is a highly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com