Infrared curing powder paint and preparation method thereof

A powder coating, infrared curing technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of high price, reduce the infrared absorption of coatings, affect the gloss and leveling of coatings, and achieve high cross-linking. The effect of density, high infrared absorption rate, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

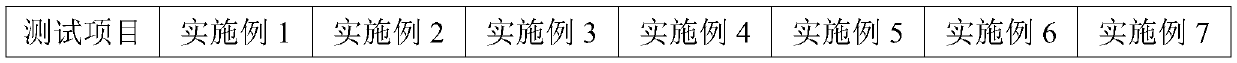

Examples

Embodiment 1

[0062] The present embodiment provides a kind of infrared curing powder coating, and its preparation method is as follows:

[0063] (1) In parts by weight, 20 parts of bisphenol A type epoxy resin (epoxy value 0.12), 30 parts of glycidyl acrylic resin (epoxy value 0.2), carboxyl polyester (acid value 70mg KOH / g ) 30 parts, self-blocking polyisocyanate (Degussa EP-BF 1320) 1.25 parts, undecanedioic acid 5 parts, hydroxyl-terminated hyperbranched polyester resin (number average molecular weight 1100, hydroxyl value 600mgKOH / g) 5 parts, nano 0.5 parts of titanium dioxide (particle size 30-80nm) and 2 parts of 2-phenylimidazoline are fully mixed and broken;

[0064] (2) Add the mixed material obtained in step (1) into an extruder, extrude at 100° C. and press into tablets, cool and pulverize to 20-80 μm, and sieve to obtain an infrared-curable powder coating.

Embodiment 2

[0066] The present embodiment provides a kind of infrared curing powder coating, and its preparation method is as follows:

[0067] (1) In parts by weight, 25 parts of bisphenol A type epoxy resin (epoxy value 0.12), 25 parts of glycidyl acrylic resin (epoxy value 0.20), carboxyl polyester (acid value 50mg KOH / g ) 35 parts, 0.75 parts of self-blocking polyisocyanate (DegussaEP-BF 1321), 4 parts of hexadecanedioic acid, 3 parts of hydroxyl-terminated hyperbranched polyester resin (number average molecular weight 2400, hydroxyl value 560mgKOH / g), 3 parts of nanometer di 5 parts of silicon oxide (particle size 30-80nm), 1.5 parts of 2-phenylimidazoline, 2 parts of leveling agent and 1.5 parts of benzoin are fully mixed and crushed;

[0068] (2) Add the mixed material obtained in step (1) into an extruder, extrude at 80° C. and press into tablets, cool and pulverize to 20-80 μm, and sieve to obtain an infrared-curable powder coating.

Embodiment 3

[0070] The present embodiment provides a kind of infrared curing powder coating, and its preparation method is as follows:

[0071] (1) In parts by weight, 30 parts of bisphenol A type epoxy resin (epoxy value 0.12), 20 parts of glycidyl acrylic resin (epoxy value 0.20), carboxyl polyester (acid value 50mg KOH / g ) 40 parts, self-blocking polyisocyanate (DegussaEP-BF 1320) 0.5 parts, dodecanedioic acid 3 parts, hydroxyl-terminated hyperbranched polyester resin (number average molecular weight 1100, hydroxyl value 600mgKOH / g) 2 parts, nano-oxidized 4 parts of aluminum (particle size 30-80nm), 1 part of 2-phenylimidazoline, 1.5 parts of leveling agent and 1 part of benzoin are fully mixed and broken;

[0072] (2) Add the mixed material obtained in step (1) into an extruder, extrude at 90° C. and press into tablets, cool and pulverize to 20-80 μm, and sieve to obtain an infrared-curable powder coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com