A pyroelectric relaxation single crystal ultra-thin sensitive chip and its preparation method

A single-chip, pyroelectric technology, applied to thermoelectric devices, thermoelectric devices with thermal changes in dielectric constant, circuits, etc., can solve the problems of low sensitivity of pyroelectric detectors, low infrared absorption rate, poor adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

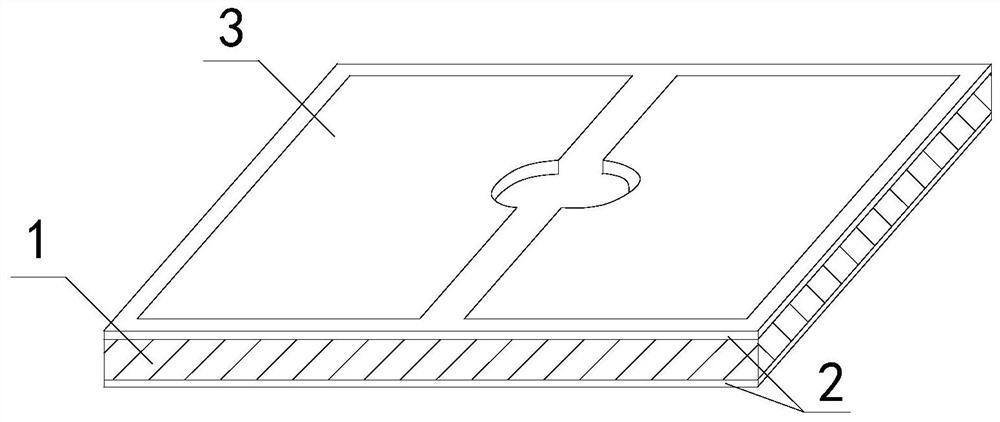

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0016] In the present invention, the grinding jig in the grinding process includes a substrate, a single wafer adsorption layer and a mask slot, the size of the slot is equivalent to that of a single wafer, the depth of the slot is fixed, and the single wafer is non-adhesively adsorbed on the card. Inside the groove, if the thickness value of the ground single wafer is equal to the depth of the groove, it indicates that the surface of the single wafer is flat, and the flatness is guaranteed to be within ±1μm.

[0017] Such as figure 1 As shown, a method for preparing a pyroelectric relaxation single crystal ultra-thin sensitive chip comprises the following steps:

[0018] Step 1: Grinding and chemical-mechanical po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com