A kind of preparation method of monoclinic zirconia nano product

A zirconia and product technology, which is applied in the field of preparation of monoclinic zirconia nano products, can solve the problems of single type of zirconium source raw materials, complex synthesis process, increased synthesis cost, etc., and achieves good application prospects, high purity, and easy operation and control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

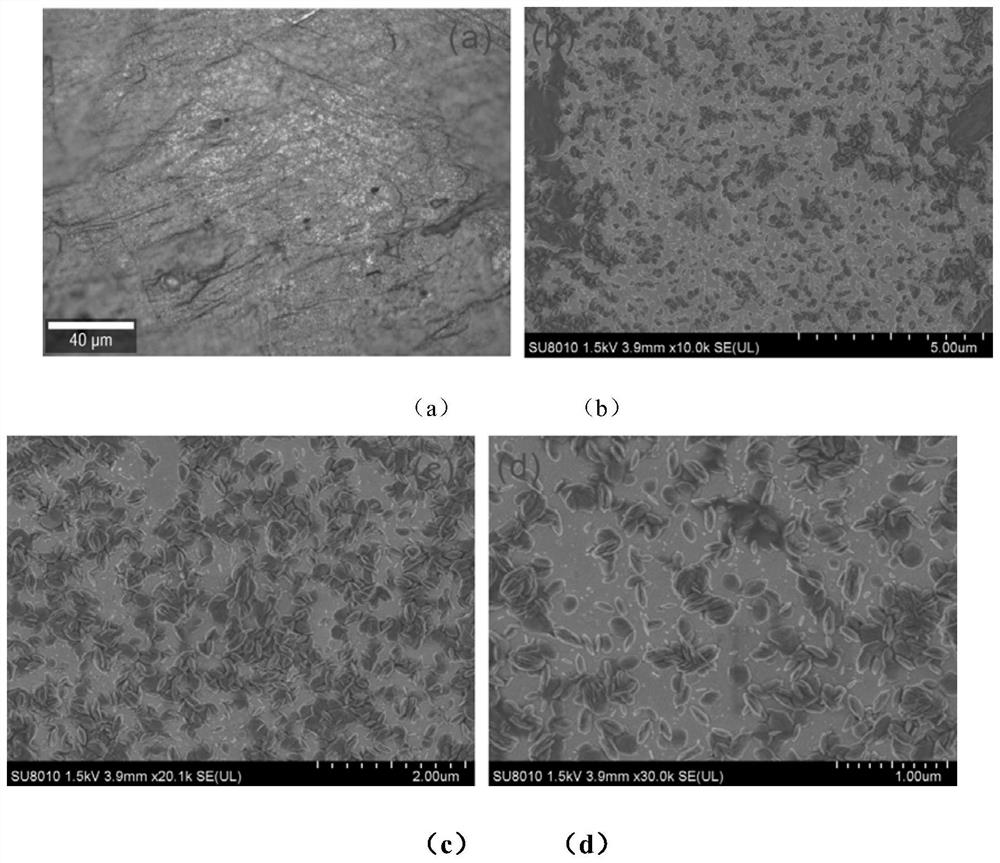

[0038] The preparation method of the monoclinic zirconia nanopowder provided in this embodiment comprises the following steps:

[0039] (1) 0.48g ammonium fluozirconate ((NH 4 ) 2 ZrF 6 , purity 99%, West Asia reagent, the same below) was dissolved in 100L deionized water and fully dissolved to obtain a 0.02mol / L reaction solution. The high-temperature and high-pressure reactor is connected with a high-precision ultra-high pressure pressure gauge, a vent pipe and a stop valve. The high-temperature and high-pressure reactor has a metal shell, and a polytetrafluoroethylene lining is arranged in the metal shell. After the reactor is tightened , inject argon gas into the kettle through the ventilation pipe to a pressure of 50MPa, close the stop valve to stop the gas injection, heat the reaction kettle through a heating furnace, and set the reaction temperature to 200°C;

[0040] (2) After the temperature rises to 200°C, open the shut-off valve in step (1), continue to add argon...

Embodiment 2

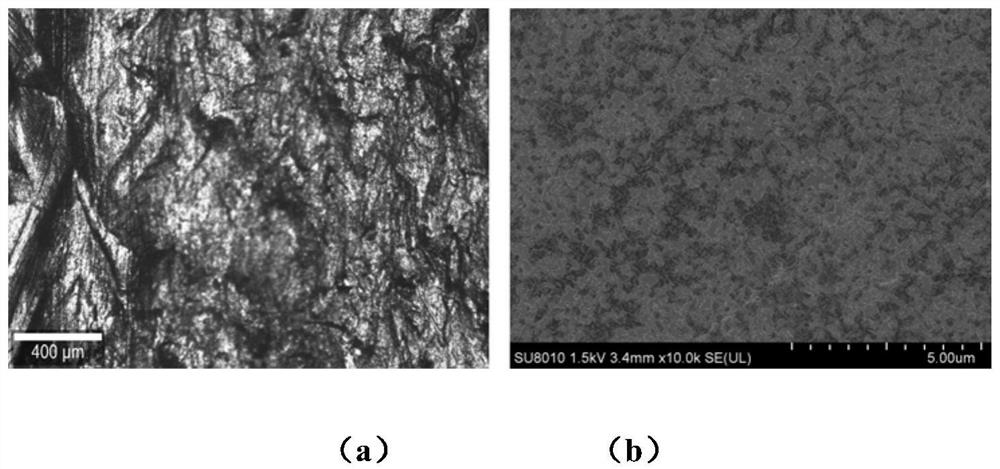

[0047] The preparation method of the monoclinic zirconia nanopowder provided in this embodiment comprises the following steps:

[0048] (1) Dissolve 0.24g of ammonium fluozirconate in 100mL of deionized water to obtain a 0.01mol / L reaction solution. Put 5mL of the prepared reaction solution into a gold tube with a diameter of 4.5mm and seal it. Then put the gold tube into the Enter the high-temperature and high-pressure reactor, after tightening the reactor, inject argon gas into the reactor through the ventilation pipe to a pressure of 80MPa, close the stop valve to stop the gas injection, heat the reactor through a heating furnace, and set the reaction temperature to 250°C;

[0049] (2) After the temperature rises to 250°C, open the stop valve in step (1), continue to add argon to the pressure of 100MPa, and keep the reaction time for 12 hours. After the reaction is completed, use ice water to pour the reactor in step (1) to carry out Rapid cooling to room temperature;

[0...

Embodiment 3

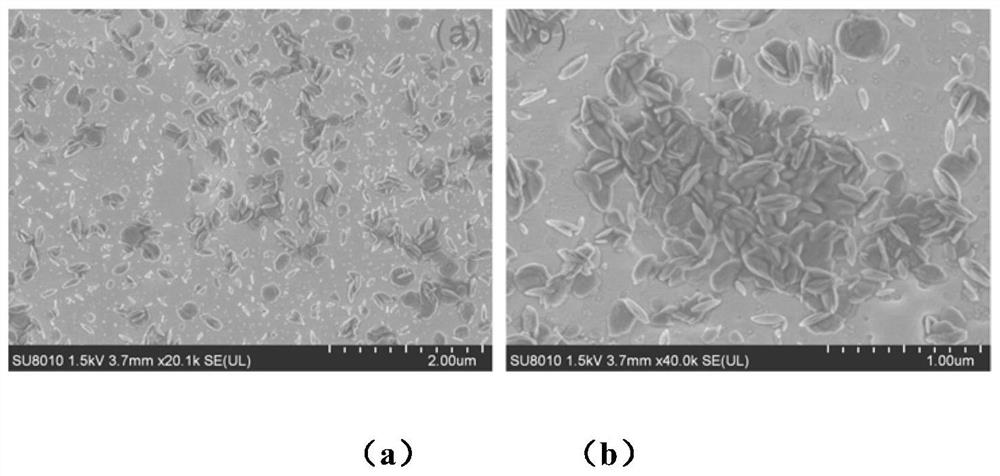

[0054] The preparation method of the monoclinic zirconia nanopowder provided in this embodiment comprises the following steps:

[0055] (1) Dissolve 0.48g of ammonium fluozirconate in 100mL of deionized water to obtain a 0.02mol / L reaction solution, put the prepared reaction solution into a hydrothermal reactor, and place a flat gold sheet at the bottom of the reactor After tightening the reactor, inject argon gas into the reactor through the ventilation pipe to a pressure of 80MPa, close the stop valve to stop the gas injection, heat the reactor through a heating furnace, and set the reaction temperature to 250°C;

[0056] (2) After the temperature rises to 250°C, open the stop valve in step (1), continue to add argon to the pressure of 120MPa, and keep the reaction time for 10 hours. After the reaction is completed, use ice water to pour the reactor in step (1) to carry out Rapid cooling to room temperature;

[0057] (3) Open the reaction kettle in step (1), recover the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com