Preparation method and application of core-shell P-CoFe2O4(at)GCN photocatalyst

A p-cofe2o4, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc. Harm, low photocatalytic efficiency and other problems, to achieve the effect of improving photocatalytic performance, modifying photocatalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

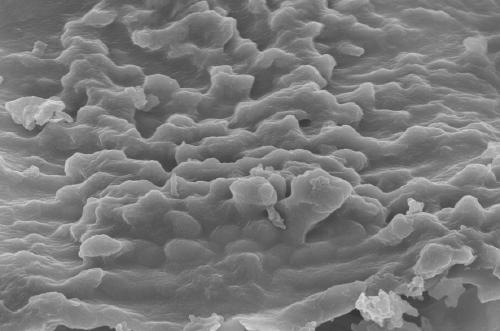

Image

Examples

Embodiment 1

[0028] A core-shell type P-CoFe 2 o 4 The preparation method of @GCN photocatalyst comprises the following steps:

[0029] a) Fully mix cobalt nitrate and ferric nitrate in equal volume for 0.5h according to the molar concentration ratio of 1:1, the reaction temperature is 35°C, and the stirring rate is 500r·min -1 ;

[0030] b) Slowly add 2mol / L potassium hydroxide solution dropwise to the fully mixed solution until complete precipitation, and react at 80°C for 3h, then rinse with absolute ethanol and distilled water several times, and dry at 60°C for 16h, Strong magnetic nanoparticles CoFe can be prepared 2 o 4 ;

[0031] c) Weigh the prepared CoFe 2 o 4 Add to 80 ml of distilled water, add thiourea and melamine polyphosphate to the mixed solution, fully stir for 5 hours, the stirring rate is 500r·min -1 , CoFe 2 o 4 , The mass ratio of thiourea and melamine polyphosphate is 0.05:1:0.2;

[0032] d) Dry the mixed solution at 80°C for 12 hours after solid-liquid sep...

Embodiment 2

[0037] A core-shell type P-CoFe 2 o 4 The preparation method of @GCN photocatalyst comprises the following steps:

[0038] a) Fully mix cobalt sulfate and ferric chloride in equal volumes at a molar concentration ratio of 1:2 for 0.5h, the reaction temperature is 45°C, and the stirring rate is 600r·min -1 ;

[0039] b) Slowly add 2mol / L ammonia solution dropwise to the fully mixed solution until complete precipitation, and react at 90°C for 4h, then rinse with absolute ethanol and distilled water for several times, and dry at 70°C for 18h. Preparation of strong magnetic nanoparticles CoFe 2 o 4 ;

[0040] c) Weigh the prepared CoFe 2 o 4 Add it to 80 ml of distilled water, add urea and phytic acid to the mixed solution, stir thoroughly for 80 hours, and the stirring rate is 700r·min -1 , CoFe 2 o 4 , The mass ratio of urea and phytic acid is 0.08:1:0.5;

[0041] d) Dry the mixed solution at 90°C for 16 hours after solid-liquid separation, and grind it into powder;

...

Embodiment 3

[0045] A core-shell type P-CoFe 2 o 4 The preparation method of @GCN photocatalyst comprises the following steps:

[0046] a) Fully mix cobalt chloride and ferric chloride in equal volumes according to the molar concentration ratio of 1:2 for 1.0h, the reaction temperature is 55°C, and the stirring rate is 800r·min -1 ;

[0047] b) Slowly add 2mol / L sodium hydroxide solution dropwise to the fully mixed solution until complete precipitation, and react at 90°C for 5h, then rinse with absolute ethanol and distilled water several times, and dry at 80°C for 24h, Strong magnetic nanoparticles CoFe can be prepared 2 o 4 ;

[0048] c) Weigh the prepared CoFe 2 o 4 Add to 80 ml of distilled water, add melamine and melamine polyphosphate to the mixed solution, fully stir for 10h, the stirring speed is 1000r·min -1 , CoFe 2 o 4 , The mass ratio of melamine and melamine polyphosphate is 0.1:1:1;

[0049] d) The mixed solution in step c) is subjected to solid-liquid separation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com