A kind of continuous firing method of boron-containing SIC fiber

A fiber and boron compound technology, applied in the field of continuous firing of boron-containing SiC fibers, can solve the problems of complex boron process, large environmental hazards, unstable boron introduction in boron oxide content gradient, etc., and achieve simple process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

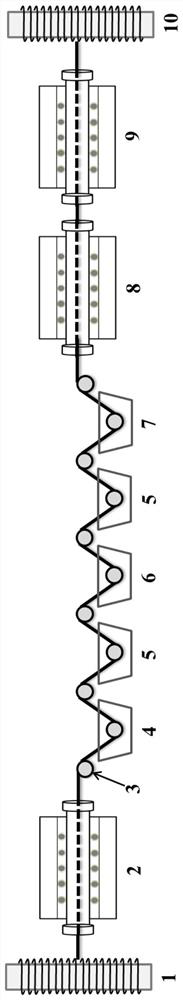

[0040] The continuous firing method of the boron-containing SiC fiber provided in this embodiment, refer to figure 1 , including the following steps:

[0041] (1) The continuous SiC fiber 1 prepared in Reference Example 2 is degummed through a nitrogen degumming furnace 2 at 500°C at a wire speed of 10 cm / min, and then transported by a roller 3 into concentrated sulfuric acid with a mass ratio of 100:50 Mixed acid pool 4 with hydrofluoric acid for pickling, deionized water pool 5 with ultrasonic device for water washing, sodium hydroxide lye pool 6 with a concentration of 40g / L for alkaline washing, deionized water pool 5 with ultrasonic device Carry out water washing to complete the surface activation treatment of SiC fiber raw materials to obtain pretreated fibers with high reactivity on the surface;

[0042] (2) Soak the pretreated fibers through the boron oxide ethanol solution pool 7 with a concentration of 20 g / L at a wire-feeding speed of 10 cm / min, and then dry them i...

Embodiment 2

[0046] The continuous firing method of boron-containing SiC fibers provided in this embodiment comprises the following steps:

[0047] (1) The continuous SiC fiber raw material prepared in Reference Example 2 is degummed through a nitrogen degumming furnace at 600°C at a wire speed of 1 cm / min, and a mixed acid of concentrated sulfuric acid and hydrofluoric acid with a mass ratio of 100:50 Pickling in the liquid pool, water washing in the deionized water pool with ultrasonic device, alkaline washing in the potassium hydroxide lye pool with a concentration of 20g / L, and water washing in the deionized water pool with ultrasonic device to complete the surface activation treatment of SiC fiber raw materials , to obtain pretreated fibers with high reactivity on the surface;

[0048] (2) soak the pretreated fiber through a boron oxide ethanol solution pool with a concentration of 40g / L at a wire speed of 1cm / min, and then dry it in a nitrogen drying oven at a temperature of 200°C to...

Embodiment 3

[0052] The continuous firing method of boron-containing SiC fibers provided in this embodiment comprises the following steps:

[0053] (1) The continuous SiC fiber raw material prepared in Reference Example 2 was degummed through a nitrogen degumming furnace at 700°C at a wire speed of 50 cm / min, and a mixed acid of concentrated sulfuric acid and hydrofluoric acid with a mass ratio of 100:100 The liquid pool is pickled, the deionized water pool with an ultrasonic device is used for water washing, the mixed lye pool of sodium hydroxide and potassium hydroxide with a concentration of 80g / L is used for alkaline washing, and the deionized water pool with an ultrasonic device is used for water washing to complete the SiC Surface activation treatment of fiber raw materials to obtain pretreated fibers with high reactivity on the surface;

[0054] (2) soak the pretreated fiber through a boron oxide ethanol solution pool with a concentration of 100g / L at a wire speed of 50cm / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com