Preparing method of angiocarpy medical equipment surface Ti-Cu-N coating with antibacterial anticoagulation smooth muscle proliferation resistance functions

A medical device, ti-cu-n technology, applied in coatings, pharmaceutical formulations, metal material coating processes, etc., can solve problems such as bacterial infection, restenosis hyperplasia, thrombosis, etc., to improve the use effect and preparation cost Low, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

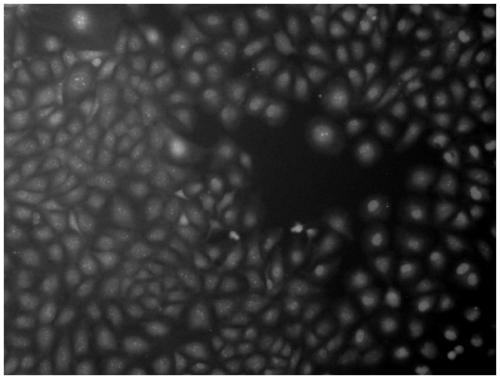

Image

Examples

preparation example Construction

[0020] A preparation method for a Ti-Cu-N coating on the surface of a cardiovascular medical device, comprising the following steps:

[0021] A. Put the cardiovascular implant device into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 0.5×10 - 3 Pa–2.0×10 -3 Pa; Introduce argon gas into the vacuum chamber until the pressure is 0.5Pa-2.0Pa, form plasma through glow discharge, sputter and clean the workpiece and sputtering target for 5-100 minutes, then turn off the argon gas and power supply;

[0022] B. Apply -50V bias voltage on the workpiece, the ratio of nitrogen and argon gas is 2 / 60-16 / 60, and the air pressure is 0.05-2.0Pa; connect the DC power supply on the target and turn it on, and adjust the power density on the target to about 0.5-10w / cm 2 , the Ti-Cu-N coating of the target product is prepared on the surface of the cardiovascular implant device; wherein the Cu doping amount is 5-50at%.

[0023] The preparation m...

Embodiment 1

[0025] A preparation method for a Ti-Cu-N coating on the surface of a cardiovascular medical device, comprising the following steps:

[0026]A. Put the cobalt-chromium-molybdenum alloy cardiovascular implant device into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 2.0×10 -3 Pa; Introduce argon gas into the vacuum chamber until the pressure is 2.0Pa; apply a DC voltage of -1000V to the workpiece, form plasma through glow discharge, and sputter and clean the workpiece and the sputtering target for 10-100 minutes, and then Turn off the power; adjust the argon pressure to 0.5Pa, apply DC sputtering power to the Ti-Cu mosaic target, sputtering current 3A, generate plasma after glow discharge, clean the target for 5-30 minutes, and then turn off the argon and power supply;

[0027] B. Apply a bias voltage of -50V on the workpiece, the ratio of nitrogen and argon to 6 / 40, and the air pressure to 0.5Pa; adjust the Ti-Cu mosaic targe...

Embodiment 2

[0030] A preparation method for a Ti-Cu-N coating on the surface of a cardiovascular medical device, comprising the following steps:

[0031] A. Put the stainless steel cardiovascular implant device into the vacuum chamber of the magnetron sputtering equipment, and the vacuum chamber is evacuated to 2×10 -3 Pa; Introduce argon gas into the vacuum chamber until the pressure is 2.0Pa, apply a DC voltage of -1000V, glow discharge to form a plasma, perform sputter cleaning on cardiovascular implants for 10-100 minutes, and then turn off the DC power supply; adjust the argon The gas pressure is 0.5Pa, respectively apply DC sputtering power supply to the sputtering target Cu target and Ti target, and the sputtering current is 3A to form glow discharge and generate plasma, clean the target for 5-30 minutes, then turn off the argon gas and power supply;

[0032] B. Introduce argon and nitrogen into the vacuum chamber respectively, the ratio of nitrogen and argon is 10 / 60, until the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com