A kind of double-scale tic particle composite strengthening low-alloy super wear-resistant steel and manufacturing method thereof

A low-alloy, wear-resistant steel technology, applied in the field of metallurgy, can solve the problems of low performance and high hardness of high-grade wear-resistant steel, achieve the effect of improving wear resistance, ensuring strength and plastic toughness, and avoiding the increase of production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of low-alloy super wear-resistant steel, comprising the following steps:

[0042] S1. Smelting: Prepare the raw materials required for smelting according to the weight percentage of the chemical composition of the above-mentioned low-alloy super wear-resistant steel; the raw materials are sequentially subjected to primary smelting in a converter, LF refining and RH refining to obtain molten steel for smelting.

[0043] S2. Solidification forming: the smelting molten steel is subjected to slab continuous casting or die casting to obtain a billet.

[0044] S3. Rolling: place the billet in a heating furnace and heat it to 1000-1250°C, and keep it warm for 3-8 hours; then use a medium-thick plate rolling mill or a hot continuous rolling mill to directly roll the billet after heating and heat preservation at high temperature for 8-16 passes , to obtain a steel plate with a thickness of 4-60 mm, and the rolling reductio...

Embodiment 1

[0050] S1. Smelting: According to the weight percentage of the chemical composition of low-alloy super wear-resistant steel, C: 0.45%, Si: 1.10%, Mn: 1.35%, Cr: 0.35%, Ti: 0.80%, Mo: 0.24%, B: 0.0005-0.003%, S: ≤0.005%, P: ≤0.015, the balance is iron and unavoidable impurity elements, and prepares the raw materials required for smelting; the raw materials are sequentially subjected to converter primary refining, LF refining and RH refining to obtain smelting molten steel.

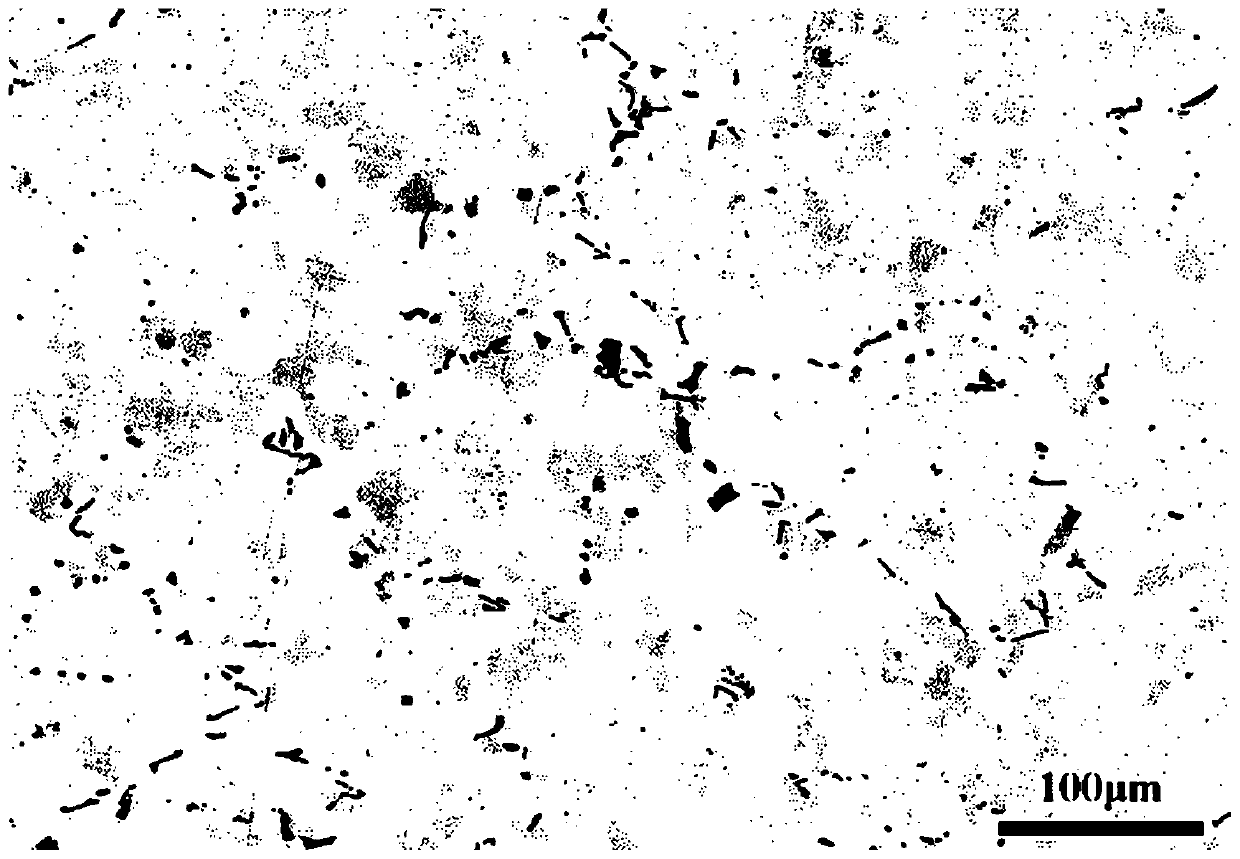

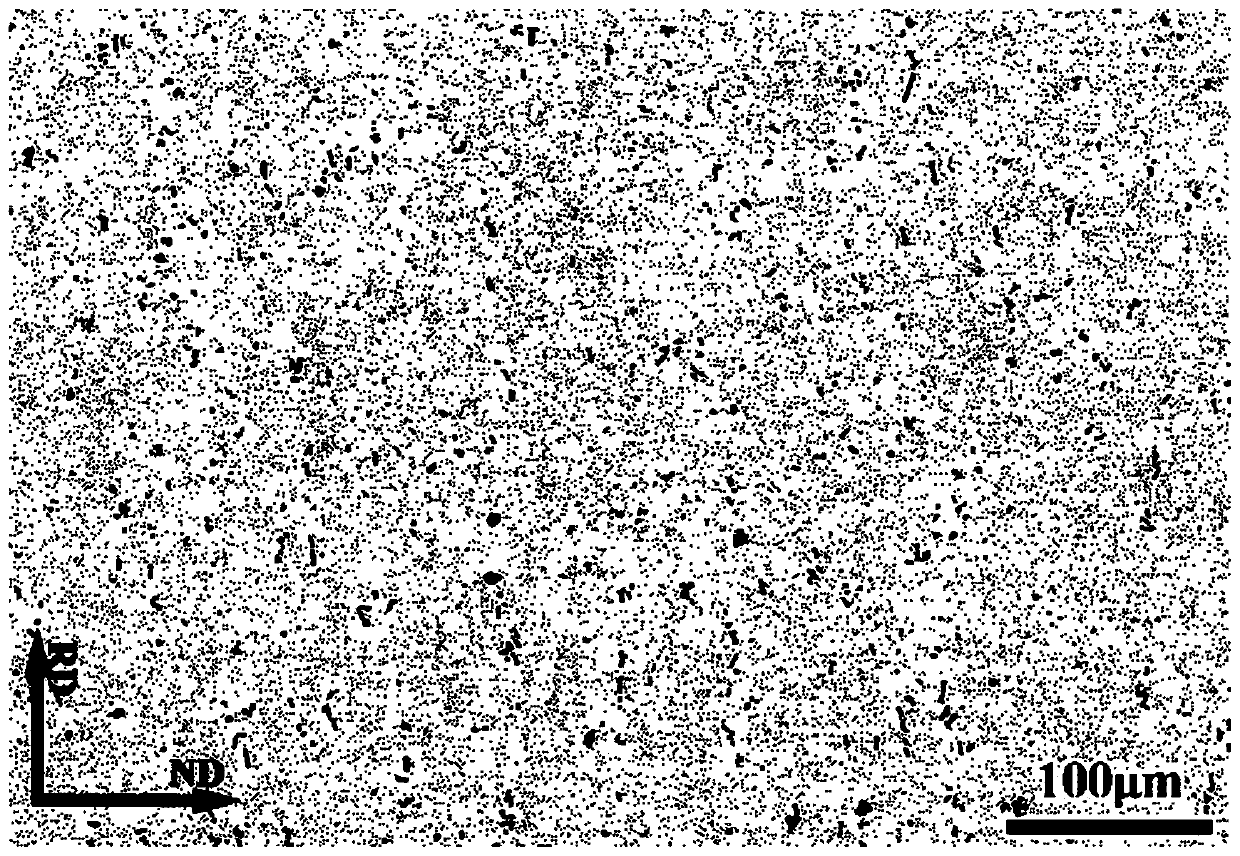

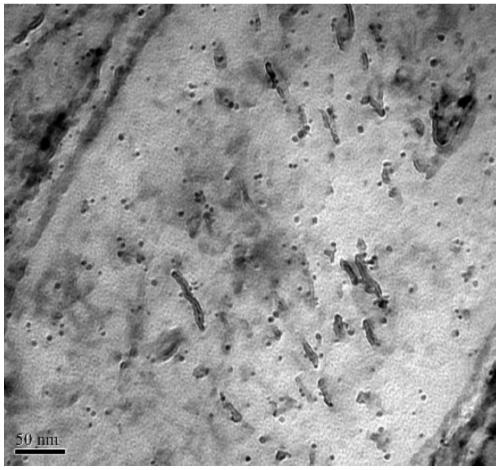

[0051] S2. Solidification forming: the molten steel is subjected to slab continuous casting to obtain a billet. Use a scanning electron microscope to observe the billet, such as figure 1 As shown, it can be seen that the micron-sized TiC particles in the blank are segregated on the grain boundary.

[0052] S3. Rolling: place the billet in a heating furnace and heat it to 1200° C., and keep it warm for 4 hours; then use a plate rolling mill to directly roll the heated and kept warm billet for 11 passes at ...

Embodiment 2

[0057] S1. Smelting: According to the weight percentage of the chemical composition of low-alloy super wear-resistant steel, C: 0.40%, Si: 0.55%, Mn: 1.32%, Cr: 0.35%, Ti: 0.60%, Mo: 0.25%, B: 0.0005-0.003%, S: ≤0.005%, P: ≤0.015, the balance is iron and unavoidable impurity elements, and prepares the raw materials required for smelting; the raw materials are sequentially subjected to converter primary refining, LF refining and RH refining to obtain smelting molten steel.

[0058] S2. Solidification forming: the molten steel is subjected to slab continuous casting to obtain a billet.

[0059] S3. Rolling: place the billet in a heating furnace and heat it to 1200° C., and keep it warm for 5 hours; then use a plate rolling mill to directly roll the heated and kept warm billet for 15 passes at high temperature to obtain a steel plate with a thickness of 10 mm.

[0060] S4. Cooling: Cool the steel plate to 600°C at a cooling rate ≥10°C / s, and then perform stack cooling.

[0061]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com