Hot-melt strippable pressure-sensitive adhesive resin as well as preparation method and application thereof

A pressure-sensitive adhesive, hot-melt technology, used in the chemical industry, can solve problems such as large solvent emissions, low cohesion, and harmful residues, and achieve the effect of high-efficiency and easy-to-operate environment and excellent peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

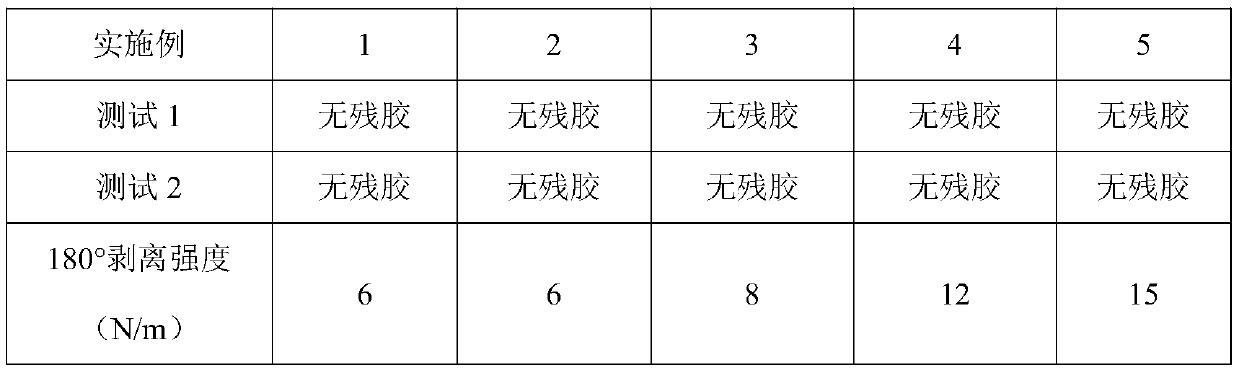

Examples

Embodiment 1

[0024] A four-neck flask with a condenser and a stirrer was heated to 120°C, filled with nitrogen, and 0.5g of 2-hydroxy-4-(methacryloyloxy)benzophenone, 5g of 2-(4-cyclohexene- 1,2 dicarboxyimide) ethyl acrylate, 20g of isooctyl acrylate, 44.5g of butyl acrylate, 30g of acrylic acid, 95g of glycidyl tert-carbonate, and 0.97g of dioctyl peroxydicarbonate are mixed evenly , 120 ° C stirring reaction for 7 hours to obtain a hot-melt peelable pressure-sensitive adhesive resin.

Embodiment 2

[0026] A four-necked flask with a condenser and a stirrer was heated to 125°C, filled with nitrogen, and 1g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl 2-acrylate, 20g of 2-(1,2 -cyclohexanedicarboxyimide) ethyl acrylate, 40g isodecyl acrylate, 29g butyl acrylate, 10g acrylic acid, 106.75g carbon 12-14 alkyl glycidyl ether and 1g dioctyl peroxydicarbonate The esters were mixed evenly, and stirred and reacted at 125° C. for 6 hours to obtain a hot-melt peelable pressure-sensitive adhesive resin.

Embodiment 3

[0028] A four-necked flask with a condenser and a stirrer was heated to 120°C, filled with nitrogen, and 0.8g of 4-acryloyloxybenzophenone, 13g of isobornyl methacrylate, 30g of isotridecyl acrylate , 34g of butyl acrylate, 22.2g of acrylic acid, 57.39g of octyl glycidyl ether and 1.1g of dioctyl peroxydicarbonate were mixed uniformly, and stirred and reacted at 120°C for 6 hours to obtain a hot-melt peelable pressure-sensitive adhesive resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com