Heat-resistant and high-crystallized enhanced PET/LCP (polyethylene terephthalate/liquid crystal polymer) alloy material and preparation method thereof

An alloy material and high crystallization technology, applied in the field of heat-resistant high crystallization reinforced PET/LCP alloy material and its preparation, can solve the problems of low notched impact strength of PBT, slow crystallization speed of PET, large molding shrinkage, etc., and achieve reduction Effects of stress and warpage, high compatibility, and low internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

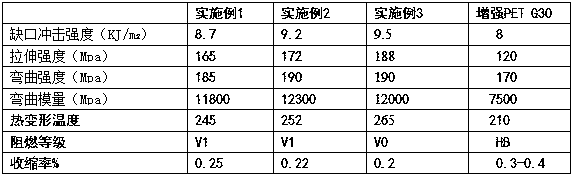

Examples

Embodiment 1

[0038] A heat-resistant high-crystallization reinforced PET / LCP alloy material comprises the following components in parts by weight:

[0039] Polyethylene terephthalate (PET) 50 parts

[0040] Liquid crystal polymer (LCP) 20 parts

[0041] 30 parts glass fiber

[0042] 0.3 part of transesterification inhibitor

[0043] 0.3 parts of coupling agent

[0044] Nucleating agent 1 part

[0045] Antioxidant 0.2 part

[0046] Lubricant 0.5 parts

[0047] 2 parts of compatible toughening agent.

[0048] Specifically, the intrinsic viscosity of the polyethylene terephthalate (PET) is 0.87.

[0049] Specifically, the liquid crystal polymer (LCP) is a copolyester liquid crystal polymer.

[0050] Specifically, the glass fiber is short glass fiber dedicated to polyester.

[0051] Specifically, the transesterification inhibitor is one or both of triphenyl phosphite and disodium hydrogen phosphate. Further, the transesterification inhibitor is SA-PGP-B transesterification inhibitor....

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that a heat-resistant high-crystallization reinforced PET / LCP alloy material includes the following components in parts by weight:

[0064] Polyethylene terephthalate (PET) 45 parts

[0065] Liquid crystal polymer (LCP) 25 parts

[0066] 30 parts glass fiber

[0067] 0.4 part of transesterification inhibitor

[0068] 0.3 parts of coupling agent

[0069] Nucleating agent 1 part

[0070] Antioxidant 0.2 parts

[0071] Lubricant 0.5 parts

[0072] 2 parts of compatible toughening agent.

[0073] The present invention also provides a preparation method of the heat-resistant high crystallization reinforced PET / LCP alloy material, comprising the following steps:

[0074] (1) Preparation of raw materials: In parts by weight, it includes 45 parts of polyethylene terephthalate (PET), 25 parts of liquid crystal polymer (LCP), 30 parts of glass fiber, 0.4 part of transesterification inhibitor, coupling 0.3 parts of...

Embodiment 3

[0079] The difference between this embodiment and Embodiment 1 is that a heat-resistant high-crystallization reinforced PET / LCP alloy material includes the following components in parts by weight:

[0080] Polyethylene terephthalate (PET) 40 parts

[0081] Liquid crystal polymer (LCP) 30 parts

[0082] 30 parts glass fiber

[0083] Transesterification inhibitor 0.5 parts

[0084] 0.3 parts of coupling agent

[0085] Nucleating agent 1 part

[0086] Antioxidant 0.2 parts

[0087] Lubricant 0.5 parts

[0088] 2 parts of compatible toughening agent.

[0089] The present invention also provides a preparation method of the heat-resistant high crystallization reinforced PET / LCP alloy material, comprising the following steps:

[0090] (1) Preparation of raw materials: In parts by weight, it includes 40 parts of polyethylene terephthalate (PET), 30 parts of liquid crystal polymer (LCP), 30 parts of glass fiber, 0.5 parts of transesterification inhibitor, coupling 0.3 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com