Nano-scale rare earth oxide-doped powder and preparation method thereof

A rare earth oxide and nano-scale technology, applied in the field of powder metallurgy, can solve the problems of uneven particle size of the second phase, uneven performance at the microscopic level, and affecting the performance of macroscopic materials, achieving high safety, reliability, and high Integrated and continuous operation, promising results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of nanoscale rare earth oxide doped powder comprises the following steps:

[0036] (1) Preparation of raw material solution:

[0037] a. Preparation of rare earth nitrate solution:

[0038] Put the rare earth nitrate in the beaker, the rare earth nitrate can be one or more of lanthanum, yttrium, cerium, etc., then add pure water, stir and dissolve while heating until the solution becomes colorless and transparent, The concentration of the rare earth nitrate solution is controlled between 0.01 mol / L and 0.1 mol / L; the heating temperature is controlled between 40-60° C., and the stirring rate is controlled between 200-500 revolutions / min.

[0039] b. Mo / W salt solution preparation:

[0040] Dissolve the Mo / W salt solution in deionized water, such as one or more of ammonium meta-X (X represents Mo / W), ammonium para-X (X represents Mo / W), or Mo / W ammonium acid obtained by the reaction of molybdenum or tungsten trioxide with ammonia water, the solut...

Embodiment 1

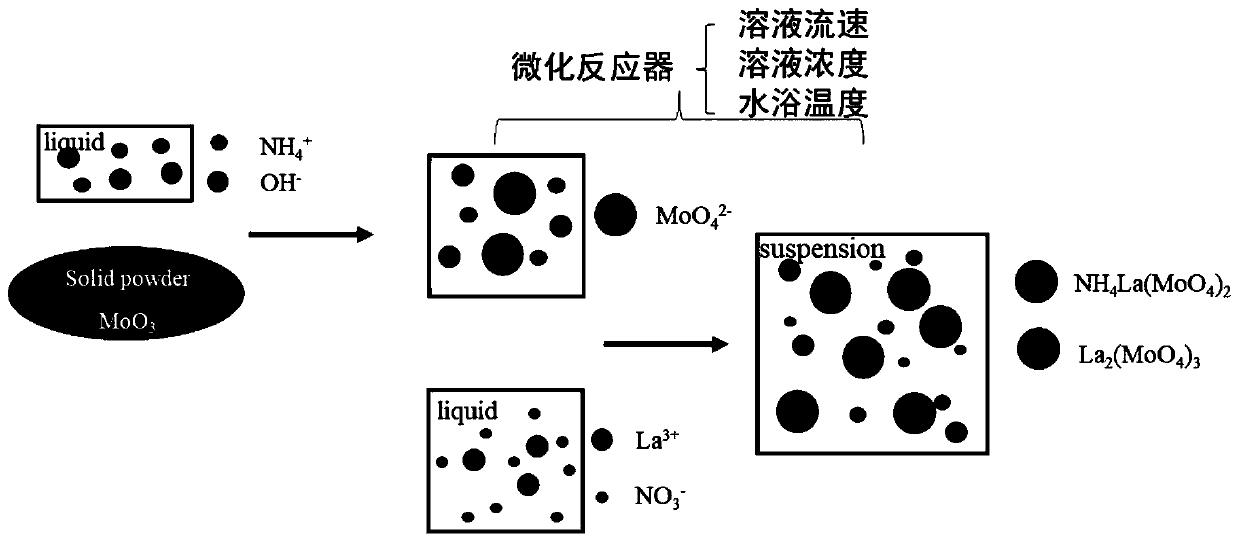

[0045] See figure 1 As shown, the raw materials of the experimental method of this embodiment are example of molybdenum trioxide, ammonia water, and lanthanum nitrate.

[0046] 1) Preparation of raw material solution: dissolving lanthanum nitrate in ionized water to obtain a lanthanum nitrate solution with a concentration of 0.035mol / L; dissolving molybdenum trioxide in ammonia water to obtain an ammonium molybdate solution with a concentration of 0.07mol / L, Stir continuously until the solution becomes colorless and transparent.

[0047] 2) Connect the lanthanum nitrate solution to the solution inlet 1 of the micronizer through a connecting tube. Connect the solution inlet 2 of the ammonium molybdate solution miniaturization reactor. The outlet 3 is connected to the reaction product collector.

[0048] 3) Check the working status of the micronizer to confirm that the instrument is operating normally.

[0049] 4) Adjust the temperature of the water bath in the micronizer, t...

Embodiment 2

[0054] The raw materials of the experimental method in this embodiment are exemplified by molybdenum trioxide, ammonia water, and lanthanum nitrate.

[0055] 1) Preparation of raw material solution: dissolving lanthanum nitrate in deionized water to obtain a lanthanum nitrate solution with a concentration of 0.046mol / L; dissolving molybdenum trioxide in ammonia water to obtain an ammonium molybdate solution with a concentration of 0.092mol / L , and kept stirring until the solution became colorless and transparent.

[0056] 2) Connect the lanthanum nitrate solution to the solution inlet 1 of the micronizer through a connecting tube. Connect the solution inlet 2 of the ammonium molybdate solution miniaturization reactor. The outlet 3 is connected to the reaction product collector.

[0057] 3) Check the working status of the micronizer to confirm that the instrument is operating normally.

[0058] 4) Adjust the temperature of the water bath in the micronizer, the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com