Preparation method of aluminum alloy sectional material for producing solar energy frame

A technology for aluminum alloy profiles and solar energy, applied in the field of aluminum alloys, can solve problems such as low production efficiency and poor product surface quality, and achieve the effects of improving corrosion resistance, high surface quality, and reducing stress corrosion cracking susceptibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

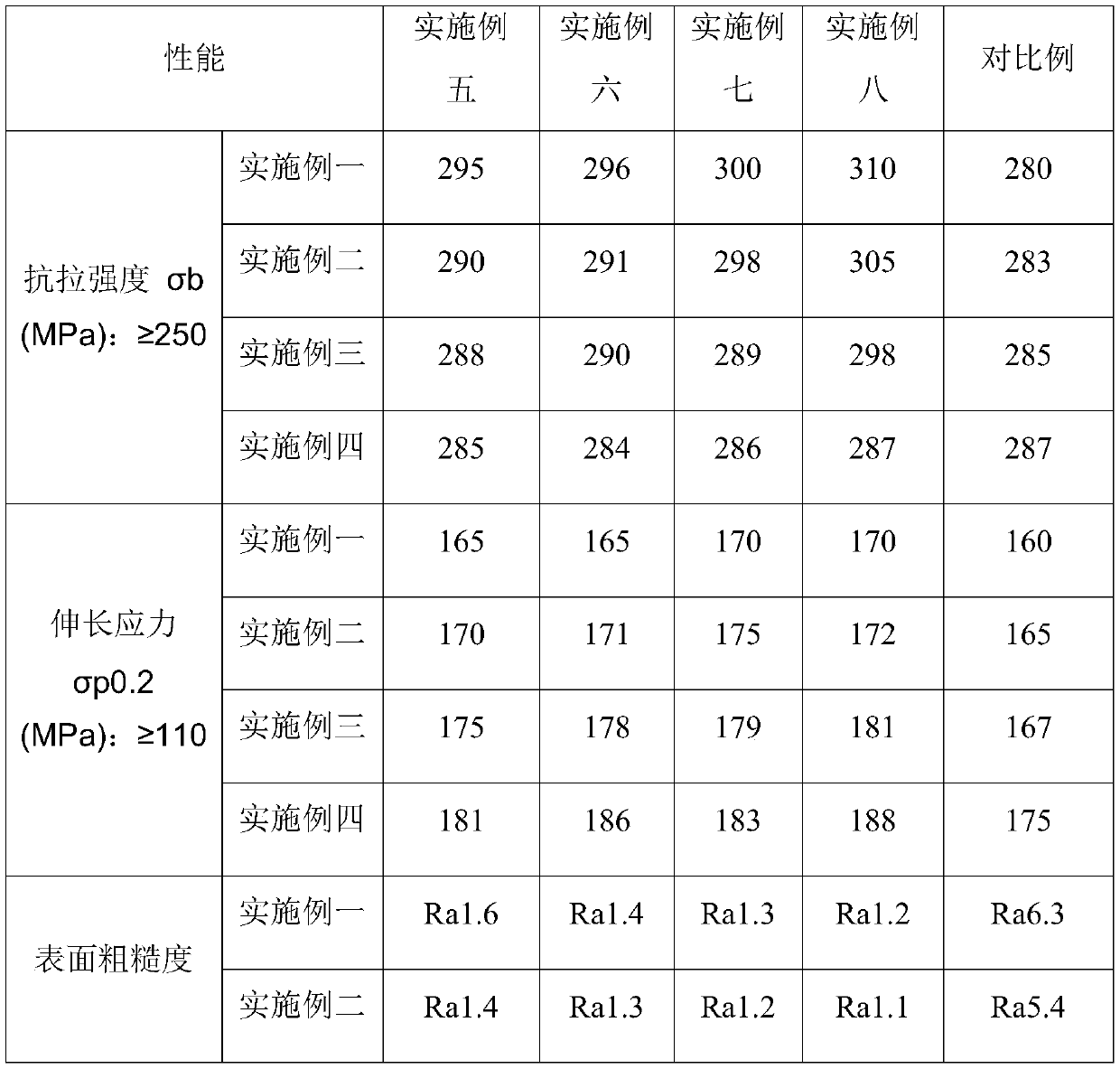

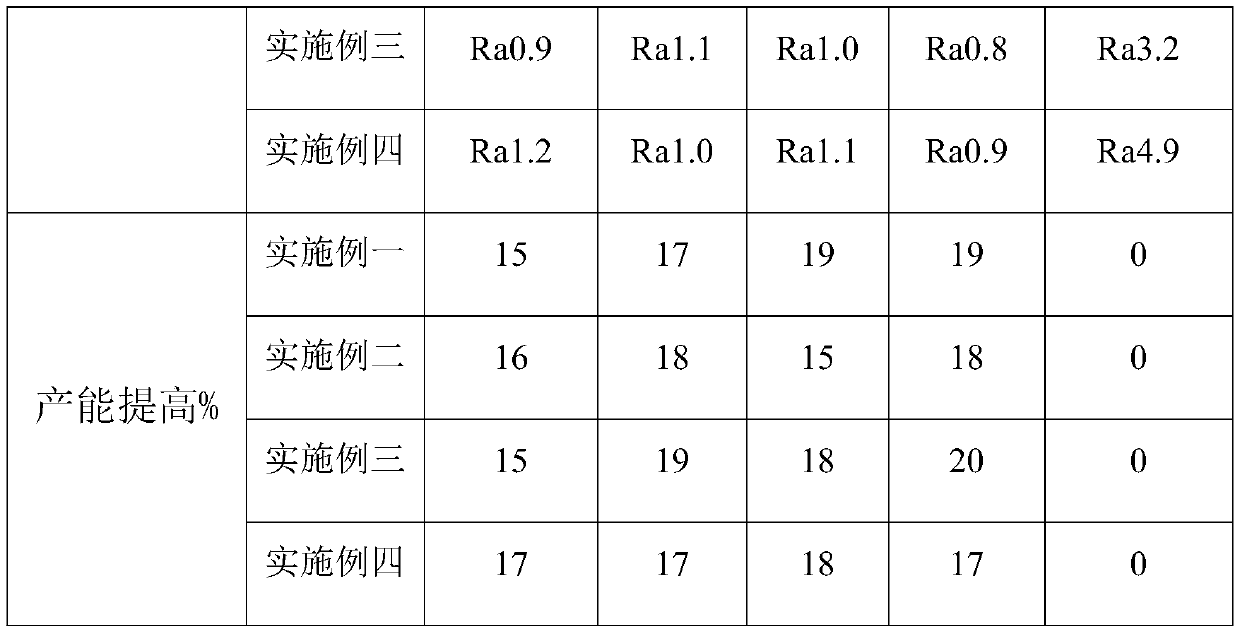

Examples

Embodiment 1

[0032] An aluminum alloy profile for the production of solar frames, the aluminum alloy is composed of the following components by weight percentage: Si0.39%, Fe 0.18%, Cu 0.04%, Mn 0.04%, Mg 0.6%, Cr 0.03%, Zn0.04 %, Ti0.03%, and the balance is aluminum.

Embodiment 2

[0034] An aluminum alloy profile for the production of solar frames, the aluminum alloy is composed of the following components by weight percentage: Si0.40%, Fe 0.15%, Cu 0.02%, Mn0.02%, Mg 0.53%, Cr0.03%, Zn0 .02%, Ti0.01%, and the balance is aluminum.

Embodiment 3

[0036] An aluminum alloy profile for the production of solar frames, the aluminum alloy is composed of the following components by weight percentage: Si0.41%, Fe 0.15%, Cu 0.02%, Mn0.02%, Mg 0.55%, Cr 0.03%, Zn0. 03%, Ti0.01%, and the balance is aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com