Chlorine ion corrosion resistant high-strength anti-seismic steel bar and production method and application thereof

A production method and steel bar technology applied in the field of metallurgy to achieve the effects of simple production process, high yield and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A method for producing steel bars, comprising the steps of:

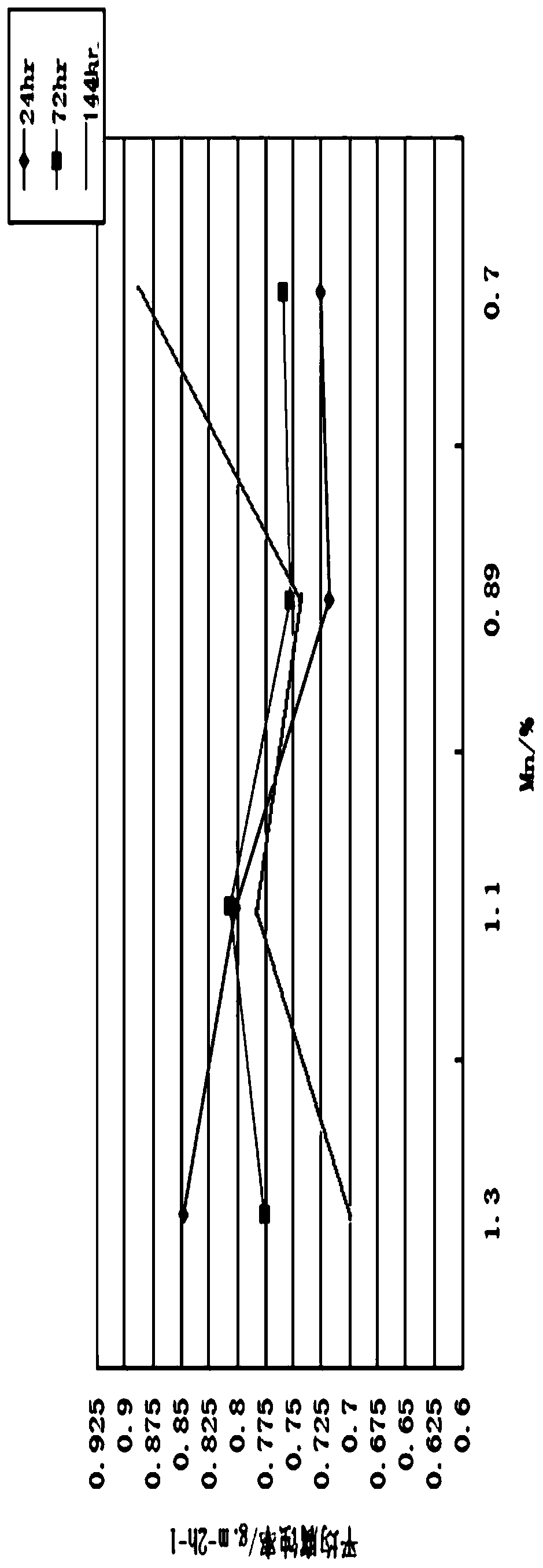

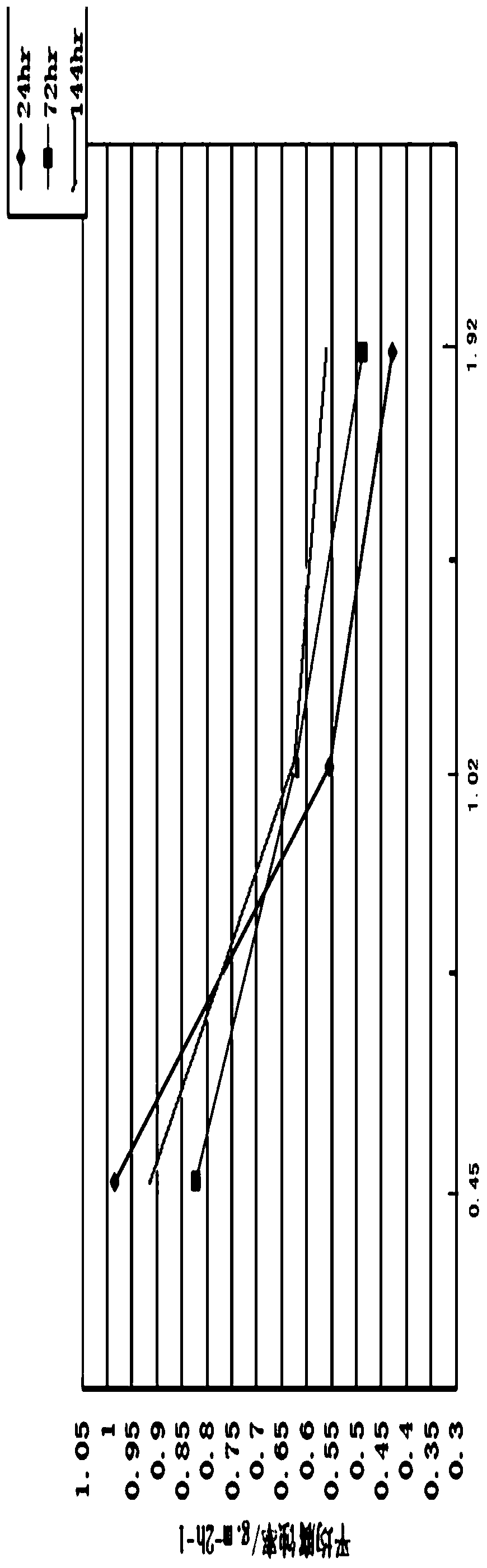

[0063] (1) Converter smelting: adding molten iron and steel scrap, according to the proportion of each element, Ni≤0.65%, Cr 0.25-7.00%, V0.028-0.029%, Ni / Cr 0.45-1.92, 0.16%≤C≤0.21% , Si≤0.80%, Mn≤1.4%, P≤0.03%, S≤0.03%, calculate and add alloys for smelting;

[0064] The alloy includes silicon-manganese alloy, silicon-iron alloy, vanadium-nitrogen alloy, high-carbon ferrochrome, nickel-iron, silicon-aluminum-barium and silicon-calcium-barium;

[0065] The temperature control parameters in the smelting process are shown in the table below:

[0066]

[0067] (2) LF furnace refining:

[0068] After the molten steel (about 120 tons per furnace) enters the station, 324kg of submerged arc slag and 40kg of fluorite are added first, and then lime is added. The lime is added in two batches to ensure that all the added lime can be completely melted. The steps of adding lime in batches are as follows: add 2 / 3 of...

Embodiment 2

[0087] A production method of a steel bar, the technological operation of which is the same as that of Example 1, the difference being the content of specific alloying elements. Specifically: 0.20% C, 0.50% Si, 1.30% Mn, 0.018% P, 0.011% S, 0.49% Cr, 0.32% Ni, 0.029% V, and the rest are Fe and unavoidable impurity elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com