A kind of aromatic modified petroleum resin and preparation method thereof

A petroleum resin and modification technology, which is applied in the field of aromatic modified petroleum resin and its preparation, can solve the problems of large catalyst usage, increase, influence on catalyst life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

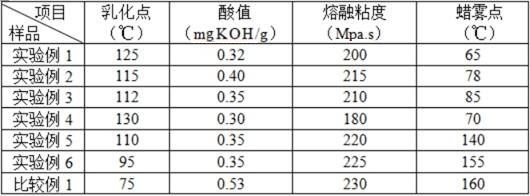

Examples

Embodiment 1

[0045] An aromatic modified petroleum resin, in parts by weight, the modified petroleum resin comprises 50 parts of C5 petroleum resin, 60 parts of n-hexane, 4 parts of maleic anhydride grafted styrene, and 20 parts of hydrogenation catalyst , C5 distillate is 80 parts, benzoyl peroxide is 3 parts.

[0046] A method for preparing an aromatically modified petroleum resin, the method for preparing an aromatically modified petroleum resin comprises the following steps:

[0047] (1) Mix 80 parts of C5 fraction with 3 parts of benzoyl peroxide and add them into the reactor, and carry out polymerization reaction at a temperature of 180°C and a pressure of 2 MPa, and the polymerization time is 6 hours;

[0048] (2) Carrying out vacuum distillation of the substance after thermal polymerization in step (1) at a pressure of -0.080MPa and a temperature of 20°C to obtain C5 petroleum resin;

[0049] (3) Take 50 parts of C5 petroleum resin in step (2), take 4 parts of maleic anhydride-gra...

Embodiment 2

[0057] An aromatic modified petroleum resin, in parts by weight, the modified petroleum resin comprises 40 parts of C5 petroleum resin, 40 parts of methylcyclohexane and normal hexane, maleic anhydride grafted styrene-ethylene-butylene 0.4 parts of diene-styrene, 10 parts of hydrogenation catalyst, 50 parts of C5 fraction, and 0.5 parts of azobisisobutyronitrile toluenesulfonate.

[0058] A method for preparing an aromatically modified petroleum resin, the method for preparing an aromatically modified petroleum resin comprises the following steps:

[0059] (1) Mix 50 parts of C5 fraction with 0.5 part of azobisisobutyronitrile toluenesulfonate and add it into the reactor, and carry out polymerization reaction at a temperature of 160 ° C and a pressure of 0.2 MPa, and the polymerization time is 1 h;

[0060] (2) Carrying out vacuum distillation of the substance after thermal polymerization in step (1) at a pressure of -0.099MPa and a temperature of 110°C to obtain C5 petroleum ...

Embodiment 3

[0069] An aromatic modified petroleum resin, in parts by weight, the modified petroleum resin comprises 60 parts of C5 petroleum resin, 120 parts of n-heptane, and 6 parts of maleic anhydride grafted styrene-butadiene-styrene Parts, 40 parts of hydrogenation catalyst, 100 parts of C5 fraction, 4 parts of diacyl peroxide.

[0070] A method for preparing an aromatically modified petroleum resin, the method for preparing an aromatically modified petroleum resin comprises the following steps:

[0071] (1) Mix 100 parts of C5 fraction with 4 parts of diacyl peroxide and add it to the reactor, and carry out polymerization reaction at a temperature of 200 °C and a pressure of 3.6 MPa, and the polymerization time is 25 hours;

[0072] (2) Carrying out vacuum distillation of the substance after thermal polymerization in step (1) at a pressure of 0 MPa and a temperature of 320° C. to obtain C5 petroleum resin;

[0073] (3) Take 60 parts of C5 petroleum resin in step (2), take 6 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com